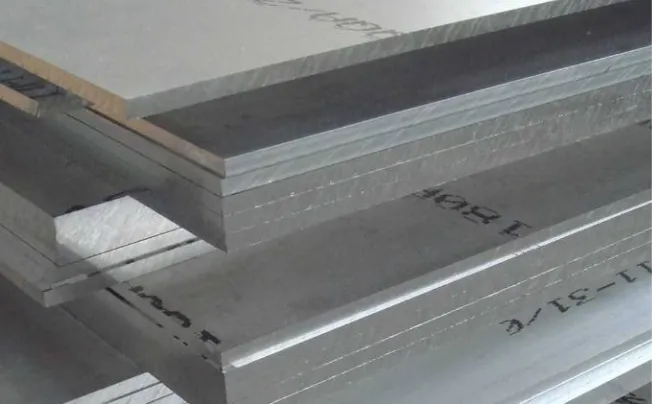

Generally speaking, stainless steel medium thickness plate refers to stainless steel plate with a thickness of 4 – 25 mm. It is often manufactured by either hot rolling or cold rolling, which offers high toughness, excellent corrosion resistance, and good processability. This provides a perfect solution to meet different applications, including steel structures, pressure vessels, shipbuilding, automobile engineering, marine projects, etc. Gnee Steel provides premium stainless steel medium-thickness plates in 321, 347, 410, and 904L grades. If you are interested, come to contact us for more!

Product Specifications

| Standard | DIN, JIS, AISI, ASTM, GB, BS |

| Grades | 321, 347, 410, and 904L |

| Thickness | 4-25 mm |

| Width | 600 – 1500 mm |

| Length | 800 – 2000 mm |

| Techniques | hot rolled and cold rolled |

| Surface | 2B, 2D, BA, NO. 1, NO. 4, NO. 8, 8K, mirror, embossed, hair line, sand blast, brushed, etching, etc |

| Package | standard export seaworthy package |

Different Types of Stainless Steel Medium Thickness Plate

Stainless medium thickness plates can be classified by strength, making method, grades, and usage. Here we take a closer look at it.

1. Strength

According to the strength classification, it is generally graded by the lower limit of the tensile strength. The stainless steel medium-thickness plate with a tensile strength above 50kgf/cm is called a high-strength stainless steel medium thickness plate.

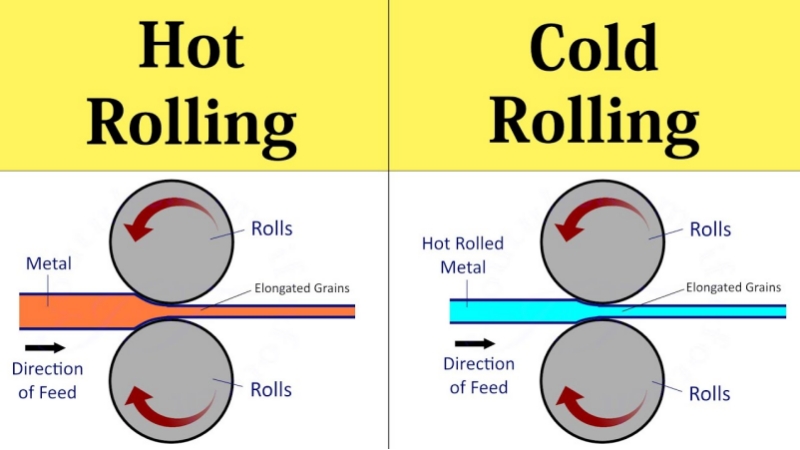

2. Making Method

This plate is often produced by rolling processes, including hot rolling and cold rolling. Correspondingly, it can be divided into hot rolled stainless medium thickness plate and cold rolled stainless medium thickness plate.

3. Grade

According to the stainless steel chemical composition and stainless steel grade table, it can be divided into:

321 stainless steel medium-thickness plates,

347 stainless steel medium-thickness plates,

410 stainless steel medium-thickness plates,

904L stainless steel medium-thickness plates.

4. Usage

As for the specific uses, this kind of plate can be categorized into:

Stainless medium thickness plate for shipbuilding: used to manufacture marine and inland ship hulls.

Stainless medium thickness plate for making boilers: used in the manufacture of various boilers and important accessories.

Stainless medium thickness plate for making pressure vessels: applied in the manufacture of pressure vessels and other similar equipment for petroleum, chemical gas separation, and gas storage and transportation.

Stainless medium thickness plate for automobile frame: used to make automobile girders like longitudinal beams and beams.

Stainless medium thickness plate for welding: used for welding parts.

Stainless medium thickness plate for special purpose: used for some particular items.

Manufacturing Process of Stainless Medium Thickness Plate

By industry standards, a stainless medium thickness plate is usually processed by rolling technique on heavy stainless steel plates. It includes hot rolling and cold rolling.

1. Hot Rolling

The billet will be heated to a certain temperature to fabricate in order to save fuel consumption. The manufacturing process includes:

Preparing billets — putting into the furnace — heating — pickling — annealing — rolling — heating — annealing — rolling (second time) — sizing — straightening — leveling — cooling — examining — testing — packing — waiting for sale

2. Cold Rolling

Using the hot rolled stainless medium thickness plate as the substrate, it is usually rolled at room temperature. By comparison, cold rolled stainless steel medium thickness plate has a brighter finish, more precise size, and better processing ability.

General Characteristics

The characteristics of SS medium thickness plate include:

1. Excellent Corrosion and Rust Resistance

It’s proven that stainless steel product has stronger anti-corrosion performance than ordinary steel in terms of air, steam, water, solution, chemically aggressive media (such as acid, alkali, and salt,) and other corrosive substances.

2. High Temperature and Oxidation Resistance

All stainless steel plates, including stainless medium-thickness plates, have high-temperature oxidation resistance, suitable for high-temperature applications whose working temperature is 1000℃. But the oxidation rate will be affected by inherent factors such as exposure environment, product shape, and stainless steel grade. Generally speaking, the higher the grade of stainless steel, the stronger the oxidation resistance.

3. High Toughness

With a thickness range between 4mm and 25 mm, the stainless medium thickness plate has high plasticity, toughness, and mechanical strength.

4. Beautiful Appearance

Its appearance is generally silvery-white and bright, which can add some extra value to your projects.

5. Environmental-friendly Solution

It is a kind of material-friendly and environmentally friendly product, which can be recycled for use to not cause pollution to the environment.

Common Uses

With the development of industry in modern society, stainless steel medium thickness plate is extensively applied to many heavy industries because of its thickness, practicality, durability, corrosion resistance, and other characteristics. It can be used in construction, petroleum, chemistry, electricity, machinery, manufacturing, transportation, and so on. Here list some examples for your reference.

1. Construction: roofing, steel structures, shipbuilding, wall cladding, stairs, building scaffolding, guardrails, protective fencing, tool steel bars, pressure vessels, pipelines, oil and gas exploration, marine engineering projects, and interior and exterior decoration of buildings.

2. Manufacturing: can be used to make stainless steel medium thickness pipes, stainless steel pattern plates, and other welding parts.

3. Transportation: railcar and automotive exhaust systems, bumpers, exterior trim, valves, certain parts of tractors, bicycle parts, engine parts, car decorations, etc.

4. Machinery: pulp and paper processing equipment, food/chemical/pharmaceutical processing equipment, metallurgical processing equipment, scrubbers for coal-fired power plants, and so on.

5. Public Uses: escalators, boilers, storage tanks, condensers, heat exchangers, flanges and fittings, furnace shells, medical instruments, tableware, hardware, reactors, armors, nuclear power plant containment, large dam gates, kitchen utensils, shelves, cabinets, etc.