Stainless steel corrugated plate, also known as stainless steel profiled plate, is a metal sheet that is rolled and cold-bent into various corrugated profiles on stainless steel plates. It has the features of good corrosion resistance, great durability, unique design, flexible affordability, light weight, fast installation, and easy maintenance. Therefore, it is extensively used in construction, commerce, residence, machinery, chemistry, transportation, agriculture, etc. For more information or to order, contact Gnee Stainless Steel Supply immediately.

Corrugated Stainless Steel Plate Specifications

| Material | stainless steel plate/stainless steel coil |

| Grade | 304, 310, 316, 321, 410, 420 |

| Standard | JIS, AISI, ASTM, GB, DIN, EN |

| Thickness | 0.2 – 12 mm |

| Width | 600 – 1500 mm (support customization) |

| Length | 800 – 2000 mm (support customization) |

| Tolerance | ±1% |

| Finish | brushed, color coated, sandblasted, polished, etc |

| Packing | PVC + waterproof or paper + wooden package |

Different Designs of Stainless Corrugated Roofing Plate

Gnee Steel offers different designs of stainless corrugated roofing sheets, including trapezoidal design, wavy design, tile design, curved design, ridge tiles, etc. Except for their different appearances, they are also different in their applications. Here we can take a simple look.

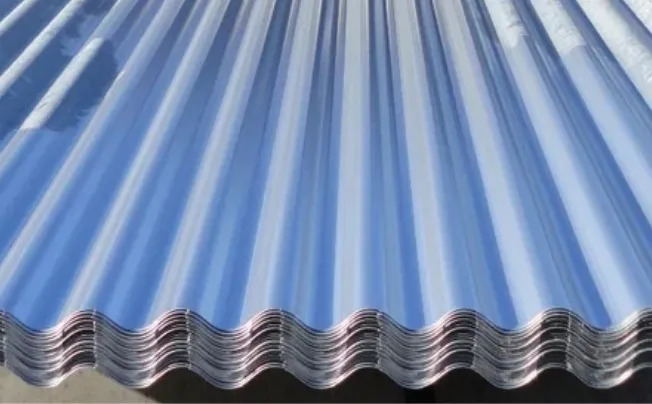

1. Curved Stainless Corrugated Roofing Plate

Curved corrugation is designed using stainless steel sheets and is offered in various sizes, dimensions, thicknesses, and designs. These roofing sheets have a variety of use in a construction structure with a large space span. Owing to easy and fast installation, they are fabricated exactly as demanded by the customers and are widely acclaimed as perfect architectural creativity.

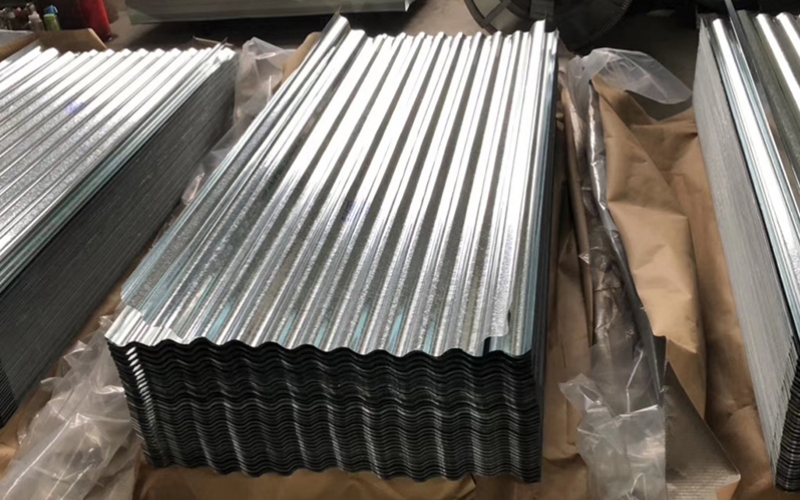

2. Wavy Stainless Corrugated Roofing Plate

The wavy corrugation is widely used as roofing or wall panels of industrial and civil buildings, warehouses, special constructions, etc. The most popular width of this type is 780mm, 836mm, 852mm, and 820mm. At Gnee Steel, we can also customize the size, length, and width of wavy stainless corrugated roofing sheets to your needs!

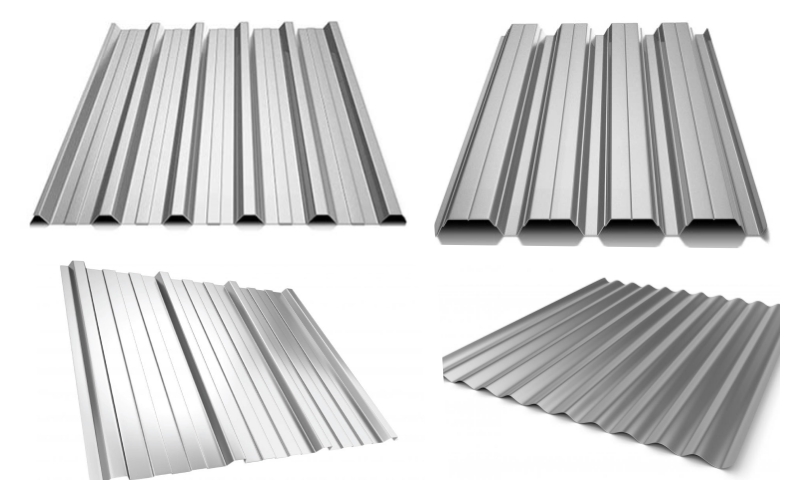

3. Trapezoidal Stainless Corrugated Roofing Plate

Trapezoid corrugation belongs to large structural stainless corrugated roofing sheet members thanks to their high load-bearing capacity. Arch fluting enables spaces of up to 20m to be bridged without having to use supports thanks to the load-bearing effect of arches. Trapezoidal roofs have excellent sound suppression characteristics. The sound reduction assessments of up to 53dB for trapezoid profiles have been tested. Despite their low weight, trapezoidal sheets are very durable. The degradative effect of wind and atmospheric effects such as acid rain have proved unable to damage them.

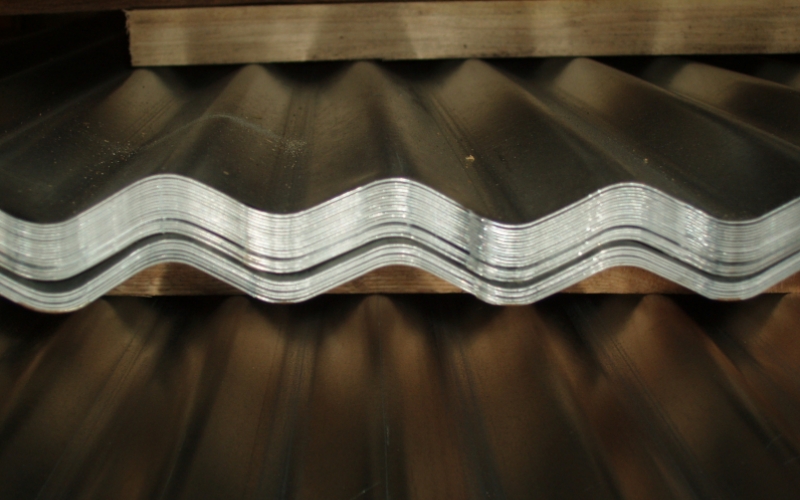

4. Corrugated Stainless Roofing Tile

Stainless corrugated roofing tile combines the attractive style of traditional tiles with the lightweight nature of stainless steel. It is an ideal material for many roofing applications, such as garden sheds, garages, summer houses, workshops, and so on. In the past, you would require dozens of individual tiles to build a roof. The whole process was time-consuming and costly, sometimes it may even endanger the safety of people who passed through the construction sites. However, now with this highly durable and easy-to-fit material, the installation speed has been largely improved and the whole construction process is safer and more environmental-friendly.

SS Corrugated Metal Manufacturing Process

Generally speaking, stainless steel corrugated sheet metal is manufactured by a roll-forming process, with metal sheets pulled off from huge round stainless steel coils before passing through rolling dies. Once the sheet metal has passed through the rollers, it is then cut into the correct panel length. This process then forms the panel into corrugated sheet metal. The corrugation process can further increase the tensile strength of stainless steel.

Product Advantages

Nowadays, stainless steel corrugated roofing panels are at the top of the list for homeowners, builders, and architects alike. That’s because it has many favorable benefits, including but not limited to:

1. Excellent Corrosion Resistance: the stainless steel material makes the plate highly resistant to corrosive elements and impacts, including intense storms such as harsh hail, rain, wind, hurricanes, temperature fluctuations, or tornadoes.

2. Unique Design: they can be easily distinguished due to their special designs. Corrugated metal starts with a stainless steel plate which is often pressed into three-dimensional patterns. More importantly, this feature can move water and moisture off a roof quickly and maintain control over internal temperatures. Besides, Gnee Steel can add color to your stainless steel corrugated plate if you need it.

3. Easy Installation & Low Maintenance: due to its light weight, these stainless corrugated panels are easy to install, just attaching to the roof with screws. Besides, metal is one of the easiest materials to maintain. Therefore, it doesn’t require monthly cleaning, yearly staining, or heavy-duty cleaning. Instead, you just need an annual look-over due to their exposed fastener system. If cleaning is required, the metal usually just needs a nice rinse and light wipe-down.

4. High Strength & Light Weight: stainless corrugated roofs are lightweight, and flexible, but incredibly robust. That’s because they have been molded to increase the hardness against horizontal and vertical loads.

5. Great Durability: like other steel products, stainless corrugated metal will last much longer than other materials. Regardless of how you use it — inside or outside –, you can expect it to last for up to 30 years. That lifetime extends even further on interior applications where the steel isn’t exposed to weather or other elements.

6. Green Choice: corrugated stainless steel roofing sheets are one of the most cost-effective roofing materials on the market today. Firstly, the main body of the corrugated plate structure can be better recycled, and excessive construction waste will not be generated during the production and installation process, thus reducing construction costs by 15-30% compared to that of concrete steel structures. Besides, corrugated metal roofing is an excellent alternative to traditional asphalt shingles or clay tile roofs.

Usage Introduction

Stainless steel corrugated plates can be used in multiple different applications. Its versatility is one of the many reasons it has remained so popular throughout the years. Here are just a few of the different ways we’ve seen our stainless corrugated panels used. The possibilities are endless!

Construction Applications

Roofing, siding, cladding, ceiling, wainscoting, commercial and civil buildings, warehouses, large-span steel structure workshops, supports and columns, retaining walls, barns, sheds, garages, etc.

Household Applications

Washing machine drums, cutlery, sinks, razor blades, microwave, oven liners, sinks, saucepans, furniture, door & window fittings, etc.

Transportation Applications

Underground stations, stadiums, ship containers, exhaust systems, car grilles, the side panels of trains, containers, trucks, and carports.

Oil & Gas Applications

Oil and gas storage tanks for wind deflection, oil & water separators, etc.

Medical Applications

Surgical implants, surgical instruments, hospitals, and so on.

Food Applications

Catering equipment, food processing equipment, brewing, distilling, etc.

Chemical Applications

Piping process, pressure vessels, chemical tankers, etc.

Public Applications

Piping and ducting, water & sewage treatment, cable trays, structural sections, shelters, handrails, drainage systems, waterproofing projects, and other interior and exterior uses.

How Much Does Stainless Steel Corrugated Metal Cost?

Frankly speaking, the price point of stainless corrugate plates heavily depends upon the specifications, grades, designs, widths, lengths, thicknesses, grades, applications, budgets, and so on. Therefore, the best way to get an accurate price on how much it costs to install a stainless corrugated metal roof is to fill out a quote form or talk to Gnee Specialist directly.