The stainless steel coil is a coiled product made of stainless steel, mainly a narrow and long steel plate produced to meet the needs of industrial production of various metal or mechanical products in different industrial sectors. As a major distributor of stainless steel iron, Gnee can provide 300 series stainless steel coils, 400 series stainless steel coils, duplex stainless steel coils, and other stainless steel coil products for customers to use to meet their diverse needs of customers.

What Is Stainless Steel Coil?

Simply speaking, stainless steel coil is an extension of an ultra-thin stainless steel plate, also called strip steel. It is an alloy steel with corrosion resistance and high-temperature resistance. The main components include iron, chromium, nickel, and other alloying elements. The stainless steel coil is a continuous roll product made by processing, cutting, and rolling stainless steel sheets. It is widely used in many industries and fields, such as construction, manufacturing, electric power, petrochemical, food processing, etc.

What Are the Grades of Stainless Steel Coil?

Stainless steel is a ferrous alloy with many advantages such as anti-fouling and anti-rust, ease to clean, corrosion resistance, durability, economy, and aesthetics. It has become the metal of choice for manufacturing materials in many industries. The stainless steel coil is the most common form of stainless steel material, and it is also the most versatile one. Our company is an ISO 9001:2008 certified stockist distributor of stainless steel strip and coil, dealing in all basic grades of stainless steel coil commonly found in the market, the current stainless steel coil products in operation are as follows:

| product | series |

type |

|

Stainless Steel Coil |

300 Series Stainless Steel Coil | 301 Stainless Steel Coil |

| 304 Stainless Steel Coil | ||

| 316 Stainless Steel Coil | ||

| 321 Stainless Steel Coil | ||

| 400 Series Stainless Steel Coil | 409 Stainless Steel Coil | |

| 410 Stainless Steel Coil | ||

| 420 Stainless Steel Coil | ||

| 430 Stainless Steel Coil | ||

| Duplex Stainless Steel Coil | 2205 Stainless Steel Coil | |

| 2507 Stainless Steel Coil |

Common stainless steel coil series include 300 series stainless steel coil, 400 series stainless steel coil, and duplex stainless steel coil, which have different alloy compositions and performance characteristics to meet different application requirements.

300 Series Stainless Steel Coil:

300 series stainless steel coil is a type of stainless steel that contains chromium, nickel, and less carbon. The most common of these are 304 stainless steel and 316 stainless steel. Known for their excellent corrosion resistance, these stainless steel coils are resistant to oxidation, acids, and alkalis and are suitable for wet and seawater environments. It also has good processability, is easy to cut, weld, and form, and is widely used in manufacturing and construction industries. High-temperature tolerance is also one of its major features.

400 Series Stainless Steel Coil:

The most common of the 400 series stainless steel coils is 430 stainless steel. Compared to 300-series stainless steels, 400-series stainless steels generally contain higher iron content and lower nickel content. This makes the 400 series stainless steel coil slightly inferior to the 300 series in terms of corrosion resistance, but better in terms of wear resistance and mechanical properties. It has good mechanical properties, high hardness, and strength, and is suitable for applications that require wear resistance. It is often used to make kitchen utensils and home appliances.

Duplex Stainless Steel Coil:

Duplex stainless steel is a special type of stainless steel that combines the properties of austenite and ferrite, hence the name “duplex”. This structure endows the duplex stainless steel coil with high strength, high corrosion resistance, and good welding performance. It has good resistance to the corrosion of chemicals such as chloride ions and can remain stable during the welding process. It is suitable for applications that require tensile strength elongation and impact resistance applications.

The selection of stainless steel coils is usually based on the characteristics and applicability of different series of stainless steel materials. If you have needs for stainless steel coils, or you have not yet found a stainless steel product that suits your needs, please feel free to contact us and we will do our best to Work hard to find it for you.

What Are the Benefits of Stainless Steel Coils?

The stainless steel coil is a kind of alloy steel, which has the characteristics of a smooth surface, high weldability, corrosion resistance, polishability, heat resistance, corrosion resistance, and so on. It is widely used in all walks of life and is an important material in modern industry. The specific advantages are as follows:

Excellent corrosion resistance: The chromium element in stainless steel reacts with oxygen in the air to form a dense chromium oxide layer, which can prevent further oxidation and corrosion. Therefore, stainless steel coils perform well in corrosive conditions such as humid environments, acidic, alkaline media, chlorides, etc.

High-temperature resistance: stainless steel coils can maintain good performance under high-temperature conditions because the alloying elements in stainless steel (such as chromium and nickel) can provide good high-temperature oxidation resistance and maintain structural stability, so stainless steel Coils are ideal for high-temperature applications such as refractories, furnaces, and heat exchangers.

Excellent mechanical properties: Stainless steel coil has high hardness, strength, and ductility, which can resist external impact and stress. At the same time, it also has good plasticity and can be made into products of various shapes and sizes by cold working, bending, etc.

Aesthetics and decoration: The smooth and bright surface of the stainless steel coil endows the product with modernity and aesthetics, and it can be polished, brushed, and coated to meet different decorative needs. It is widely used in construction, interior design, furniture manufacturing, and other fields, such as doors and windows, railings, columns, kitchen utensils, household items, etc.

Hygienic and easy to clean: Stainless steel coil is a hygienic and safe material with antibacterial properties, which is not easy to breed bacteria and microorganisms. In addition, its smooth surface does not absorb dirt, is easy to clean, and is resistant to corrosion and chemical attack, making it an excellent performer in food processing, medical equipment, sanitation facilities, and more.

How to Choose the Right Type of Stainless Steel Coil?

There are several key factors to consider when choosing the right size stainless steel coil. Here are some suggestions to help you make an informed choice:

Environment And Application:

Consider the environment in which you will use the stainless steel coil. If you need to resist corrosion and oxidation, it is recommended to choose 300 series stainless steel coils with good corrosion resistance, such as 304 and 316 stainless steel; for high-temperature applications, you need to choose stainless steel coils with excellent high-temperature resistance; for high strength and wear resistance For permanent applications, you can consider choosing 400 series stainless steel coils, such as 430 stainless steel.

Physical Properties:

Depending on your specific needs, consider the physical properties of stainless steel coils such as hardness, strength, and ductility. 300 series stainless steel coils generally have lower hardness and strength, but have good ductility, suitable for applications that require bending and forming; 400 series stainless steel coils have higher hardness and strength than 300 series stainless steel coils, and are suitable for applications requiring higher Applications with mechanical properties and wear resistance; duplex stainless steel coils have high toughness and are suitable for applications requiring tensile and impact resistance.

Solderability And Processability:

If you need to do welding or machining, make sure to choose a stainless steel coil with good weldability and machining properties. 300-series stainless steel coils generally have good welding properties, while 400-series stainless steel coils may be relatively poor. Duplex stainless steel coils have better welding performance and can maintain stable performance during the welding process.

Relevant Standards And Specifications:

Learn about relevant standards and codes based on your industry and application requirements. Ensure that the stainless steel coil selected meets the applicable quality standards and specification requirements.

Cost-effectiveness:

Consider the cost-effectiveness of stainless steel coils. The price of stainless steel coils of different models and series will vary. According to your budget and project requirements, choose the suitable model.

The above are just some reference opinions we provide when choosing stainless steel coil products. The final selection of suitable stainless steel coils should be comprehensively evaluated according to specific applications and needs. If you can’t make a choice or have some questions, please feel free to consult us, and we will provide you with the most professional solutions.

What Are Stainless Steel Coils Used for?

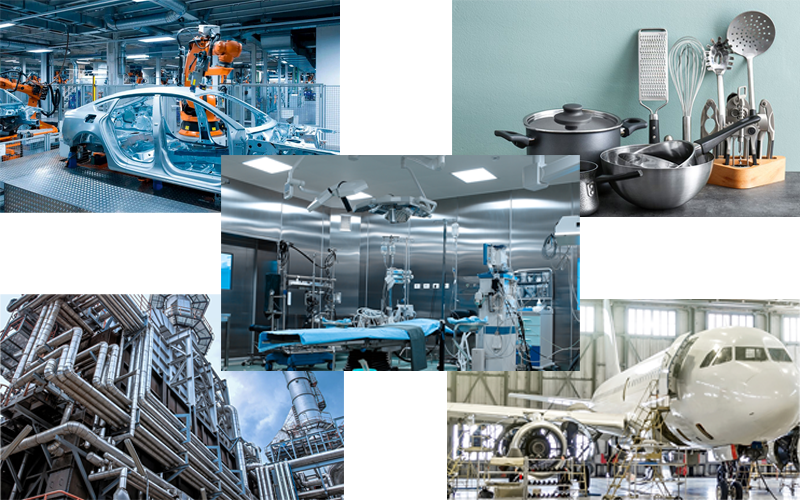

Due to its excellent characteristics, stainless steel coils are widely used in many fields and industries. Below are some of our application areas:

Automobile industry: Stainless steel coil is an ideal choice for auto parts and can be widely used in automobile manufacturing, such as manufacturing bodies, exhaust pipes, intake pipes, wheel covers, body decoration, etc. Stainless steel coils are used to manufacture the body structure of automobiles, providing strength and stability, and helping to improve the collision safety performance of automobiles; used to manufacture exhaust pipes and intake pipes, stainless steel coils are resistant to high temperature and corrosion, and are suitable for various Environment and working conditions; used in the manufacture of wheel covers, stainless steel coils have good wear resistance and stylish appearance, which can improve the aesthetics of vehicles.

Kitchen utensils: Stainless steel has the characteristics of corrosion resistance and high-temperature resistance, it will not chemically react with food, and at the same time it is easy to clean, modern, and beautiful, it is an ideal material for kitchen utensils. It can be used to make kitchen utensils, washbasins, sinks, countertops, door and window frames, etc.

Chemical and petroleum industry: Stainless steel has high corrosion resistance to corrosive media. It is used in the chemical and petroleum industries to manufacture storage tanks, pipes, valves, heat exchangers, and other equipment to ensure the safe and reliable operation of the equipment.

Aerospace field: Due to its high strength, lightweight and corrosion resistance, stainless steel coils are used in the aerospace field to manufacture aircraft parts, such as wings, engine casings, hatches, etc., which improve the performance and durability of the aircraft. In addition, it can also be used to manufacture structural components of missiles and satellites. The excellent performance of stainless steel coils in extreme environments can ensure the reliability of equipment.

Medical field: Stainless steel coils have good hygienic performance and corrosion resistance, and are also non-toxic, easy to clean, and have good mechanical properties. They can be used to manufacture medical and surgical instruments, such as scalpels, syringes, surgical instruments, etc.

The above are just some common application suggestions. With the advancement of technology and changes in demand, stainless steel coils can also play a role in other fields. If you have related needs, please feel free to contact us, we will provide you with the most professional opinions, the most suitable products, and the best service!