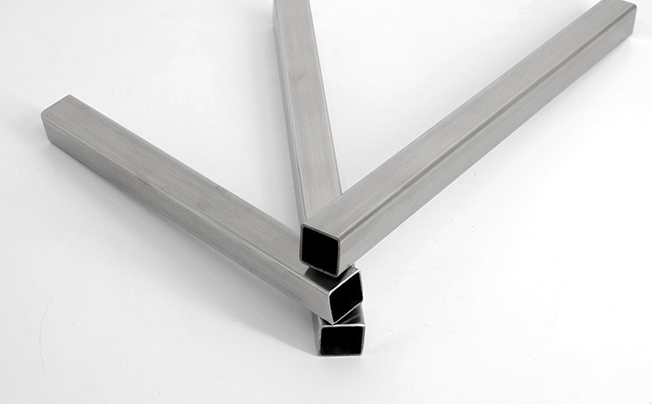

A stainless steel tubular product with a square cross-section is known as a stainless steel square tube. It is one of the materials that is frequently used in industrial production and is typically formed from stainless steel plates through cutting, crimping, welding, etc.

What is the difference between tubing and piping?

Production: Using a stainless steel strip, the pipe is extruded into a circular shape before being online welded. The tube is first created as a round tube, and then it is extruded through the mold into a square tube.

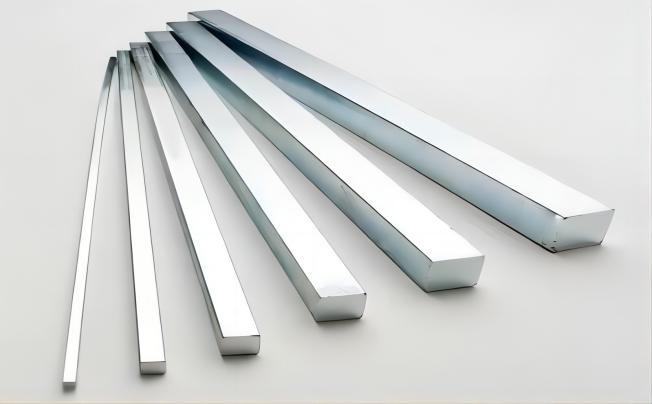

Walls of pipes and nozzles: Most pipe interior and exterior walls are polished, and the tubes are buffed. The brushed surface can lessen the presence of scratches because the tube is susceptible to scratches. Regarding the pipe mouth, the tube cannot be treated; however, the pipe can be processed by flaring, shrinking the tip, reducing, crimping, chamfering, etc.

Structural stress: The surface force of the pipe is more uniform; The tube has four angles of 90 degrees, which is not easy to rotate and twist, and is firmer when fixing certain objects.

Application: In terms of fluid transportation, pipes are preferred, because the inner and outer walls of the pipe wall can be polished, do not easy to accumulate scale, and are simple to clean; In terms of structural support, tubes will be used, and their resistance torque is stronger than that of pipes.

Specification and Grade of Stainless Steel Square Tube

| Wall Thickness(WT) | 10mm-300mm or more |

| Side Length(SL) | 0.5mm-6mm or more |

| Standard | ASTM, DIN, ISO, etc. |

Different dimensions standards, units, and wall thickness options may be used in various nations and areas. As a result, particular specifications must be chosen and verified by making use of the pertinent standards and criteria.

What grade is square tubing made of stainless steel? It comprises the following grades for diverse industrial applications: 304, 321, 316L, and 347.

Characteristics and Applications

1. It contains a high proportion of chromium, and corrosion resistance is good, so it can be used in chemical equipment, liquid storage, transportation, food processing and medicine, and other fields which are usually containing acid, alkali, and other corrosive media humid and corrosive environment. But corrosion resistance characteristics help reactors, storage tanks, pharmaceutical pipelines, food processing equipment, and other applications.

2. Due to its high-temperature resistance, durability, and good seismic resistance, it is also widely used in the production of furniture, automobiles, and transportation. It can provide good safety, durability, and bearing capacity for body frames, ship pipelines, automobile exhaust systems, table and chair structures, etc., and is difficult to deform, loosen, or oxidize.

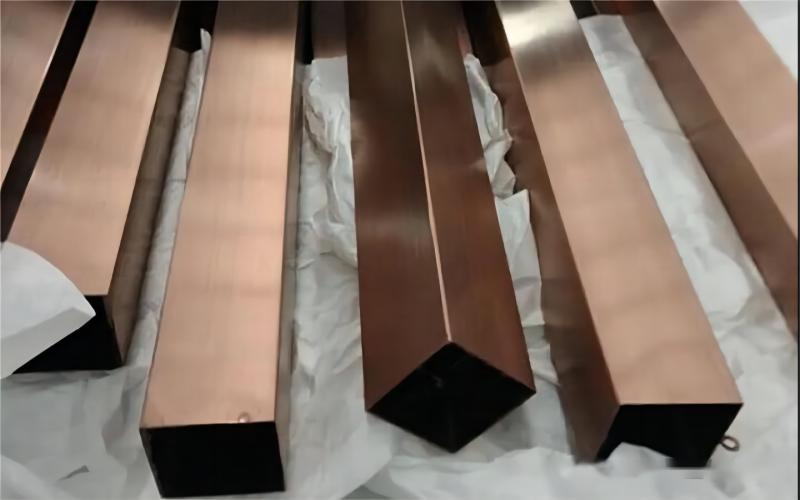

3. The surface of stainless steel square tube is smooth, bright, and elegant appearance, can be formed by cold working and hot working and other processes, to obtain a variety of different shapes and sizes of pipes, and does not easy to accumulate dust, stains, etc., easy to clean and maintain. These properties make it an ideal building material, so it is often used in the structure and decoration of buildings, such as railings, handrails, ceilings, door, and window frames, etc.

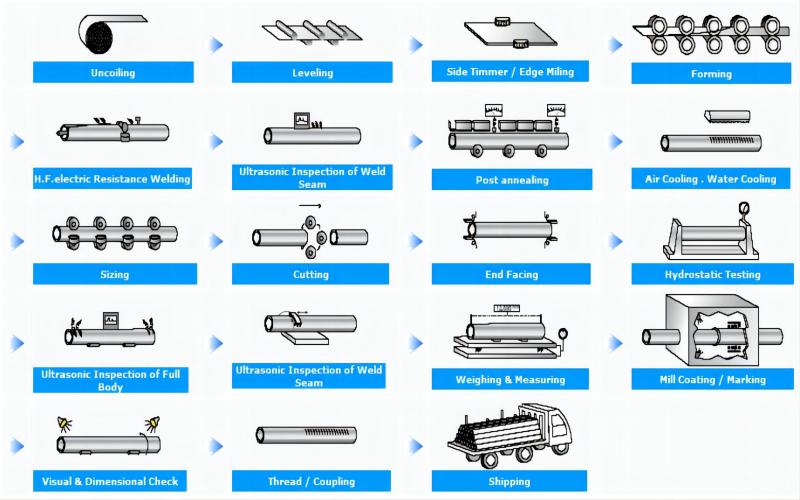

How are square tubes manufactured?

Round bar preparation, heating, hot rolled perforation, head cutting, acid pickling, regrinding, degreasing, cold rolling processing, solution heat treatment, straightening, tube cutting, acid pickling, and finished product inspection are the steps involved in making a stainless square tube.

It should be noted that the raw material starts in the form of a hot extruded seamless tube, and then cools and processes a long and straight form through the tube reducer. For longer-length tubes, the cold reduction is the most efficient manufacturing method.

Why choose to stainless steel square tube?

Superior quality means that it won’t corrode easily, can withstand corrosive media, and has a steady, robust bearing capacity, making it extensively used, safe, and dependable.

Environmentally sound and hygienic: Recyclable stainless steel square pipe has a low impact on the environment and complies with the idea of sustainable development.

Economical and useful: For consumers, a fair price is the most crucial factor. Due to the manufacturing method, stainless steel square tube is somewhat more expensive than stainless steel seamless pipe, but overall, stainless steel square pipe is worth purchasing high-quality and affordable goods.

Market Competition and Prospect

Market rivalry for stainless steel square tubes is strong. Numerous players on the market provide it in a variety of sizes, grades, and specifications. In the upcoming years, the demand for stainless steel tubes is anticipated to rise due to reasons like rising demand from the construction, automotive, and industrial sectors. Product quality and price strategies are being improved through innovation and market rivalry. To obtain a competitive edge, several businesses concentrate on enhancing their management and quality control programs. A number of efforts will also be implemented to deepen its specialization. Overall, there is fierce competition in the stainless steel square tube industry, and businesses are continuously looking for ways to set themselves apart through innovation, pricing, and quality.

Attention to Using Stainless Steel Square Tube

First, it’s simple to make and weld stainless steel square tubes. When cutting pipes, caution should be taken to prevent material damage by using the proper equipment and methods. Then, the entire appearance and feel are then influenced by its surface treatment. It is crucial to select a surface treatment appropriate for the pipe’s intended function. Third, stainless steel square tube is more robust and long-lasting. However, a variety of factors, like the type of steel used, the tube’s wall thickness, and its size, will have an impact on the tube’s strength. Making ensuring the tube can support the anticipated load or weight is crucial.

Gnee Steel Group is a supply chain enterprise integrating the design and processing of panels, pipes, profiles, outdoor landscaping, and the sales of international small products. It was established in 2008 with a vision to be the most competitive supply chain group in the global; ever since then, we have always been dedicated to fulfilling that vision with excellent, consistent, and innovative services. After several years of hard work, Gnee Steel Group has become the most professional steel supply chain international enterprise in the Central Plains.