Stainless Steel Round Hole Plate Introduction

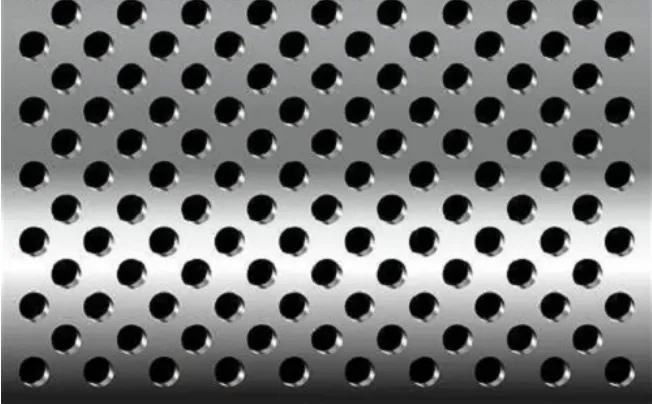

Stainless steel round hole plate is a type of metal that punches/perforates on stainless steel plates to form round hole patterns by mold. The round hole perforation is the most popular type of perforated pattern. Why?

Geometrically, a round hole is the most solid shape. What’s more, round rolls are manufactured relatively easily with aesthetic effects, which makes the round hole perforated sheet cheaper than any other perforated sheet with other hole patterns. Therefore, the round hole pattern becomes the most popular shape.

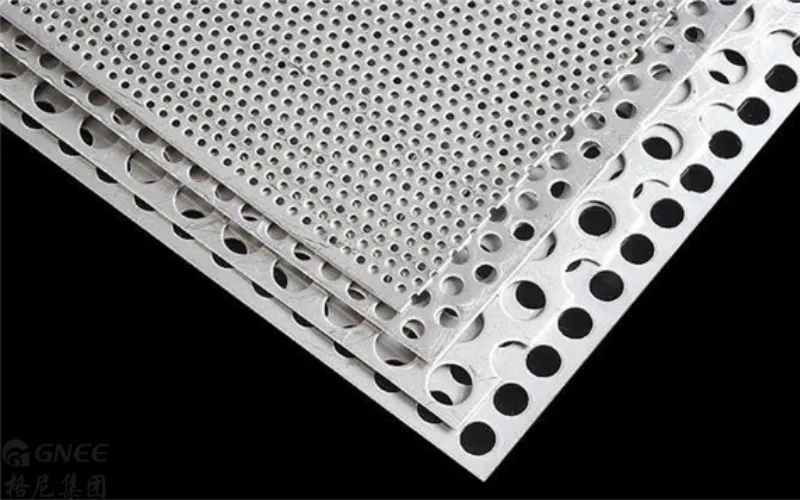

Stainless Steel Round Hole Plate Specification

| Raw Material | stainless steel plate |

| Standards | JIS, AISI, ASTM, GB, DIN, EN |

| Grades | 304, 310, 316, 321, 409, 410, 420, etc |

| Thickness | 1 – 12 mm or according to the customer’s requirements |

| Width | 600 – 1500 mm or according to the customer’s requirements |

| Length | 800 – 3000 mm or according to the customer’s requirements |

| Hole size | 0.2 -155 mm or according to the customer’s requirements |

| Hole patterns | round |

| Finish | 2B, 2D, BA, No 4., HL, 6K/8K, brushed, polished, etc |

| Punching arrangement methods | straight row (90 degrees straight ), staggered row (60 degrees staggered or 45 degrees staggered), irregular row, combination arrangement of large and small holes, etc |

| Value-added service | cutting, rolling, folding, welding, bending, etc., |

| Supply Form | in rolls/panels |

| Package | plastic film packing and pallet transportation, or according to the customer’s requirements |

Stainless Steel Round Hole Plate Manufacturing Process

The production process of stainless steel round-hole perforated plates is shown as follows:

1. First select the material: stainless steel plates.

2. Prepare the mold with round holes.

3. Punching.

4. Plate cutting: cut the plate into the required size according to the customer’s needs.

5. Flattening: use a straightening machine to restore the punched plate to its original flat state after punching deformation.

Stainless Steel Round Hole Plate Features

1. Good Corrosion Resistance

One of the main benefits of using stainless steel for this mesh is its strong resistance to rust and corrosion. This makes the product durable, especially in environments exposed to moisture or chemicals.

2. Hole Design

The round hole design can provide a range of functional and decorative features.

For example, it ensures the passage of light, liquid, sound, and air, making it an excellent choice for ventilation, filtration, screening, and other applications. Additionally, the uniform perforations can serve aesthetic purposes, lending a modern look to architectural or design projects.

3. Light Weight

The perforation design also makes it much lighter than stainless steel plates of the same size.

4. Easy Maintenance

The stainless steel material provides a smooth surface. This makes it easy to clean and maintain, reducing the need for frequent cleaning and maintenance.

Stainless Steel Round Hole Plate Applications

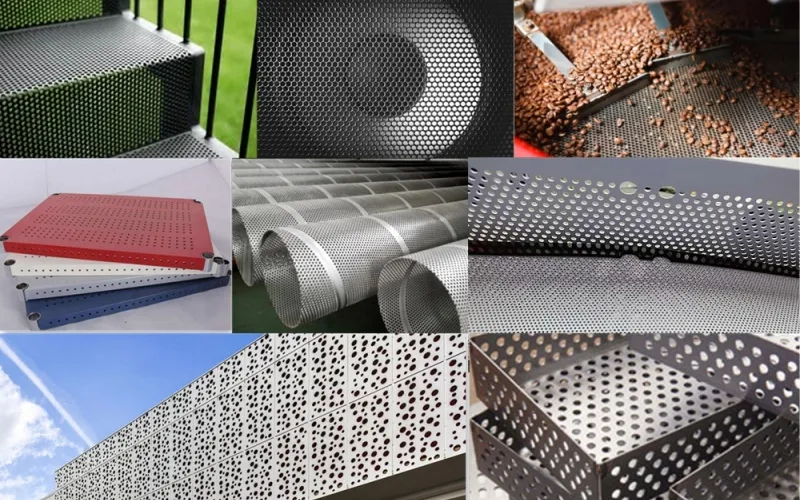

Today, the perforated ss round hole sheet has been applied in various fields to achieve the purpose of sound insulation, decoration, ventilation, and filtration. Typical examples include:

Cladding, walling, partitions, and ceiling panels

Sunshade and sunscreen

Filters for grain sieving, sandstone, and kitchen garbage

Decorative banister and balustrade panels

Protective guards of machine equipment

Ventilation sheets such as air condition grilles

Noise reduction panel

daily furniture like fruit baskets, food covers, tables, benches, shelves, etc

Shopping mall display signage

Diffusers or covers for lighting fixtures

Animal fencing meshes

Contact Gnee Steel for Stainless Steel Plates with Round Holes

If you are looking for round-hole perforated stainless steel sheets, Gnee offers a variety of options in terms of thickness, sizes, hole patterns, and open area percentage. As the world’s leading supplier of stainless steel products, Gnee Stainless Steel provides customers with high-quality stainless steel round hole plates and other stainless steel products at very competitive prices.