What Is Stainless Steel Reducing Tube?

Stainless steel reducing tube is a pipe fitting that is used to connect stainless steel pipes or tubes of different sizes. It is designed to decrease the diameter at one end, allowing for a seamless connection between pipes or tubes of varying sizes.

Stainless Steel Reducing Tube Specification

| Raw Material | stainless steel pipe, stainless steel plate |

| Standard | JIS, AISI, ASTM, DIN, SUS, EN, GB |

| Certifications | ISO 9001, SGS, BV, GB |

| Grades | 304, 310, 316, 321, 410, 420, etc |

| Thickness | 1.5 – 26 mm or as customer’s requirements |

| Shapes | stainless steel concentric reducers, stainless steel eccentric reducers |

| Delivery time | within 7-10 working days |

*Notice:

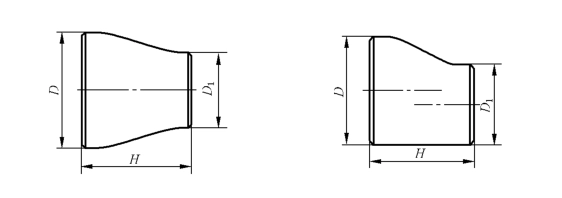

The roundness of the eccentric reducer should not be greater than 1% of the outer diameter of the corresponding end, and the allowable deviation is ±3mm; the center lines of the two ends of the concentric reducer should coincide, and the allowable deviation of the eccentricity value is ±5mm.

Stainless Steel Reducing Tube Types

Stainless steel reducing types can be divided into different kinds according to shape, manufacturing process, and grade. Let’s see below.

1. Shape

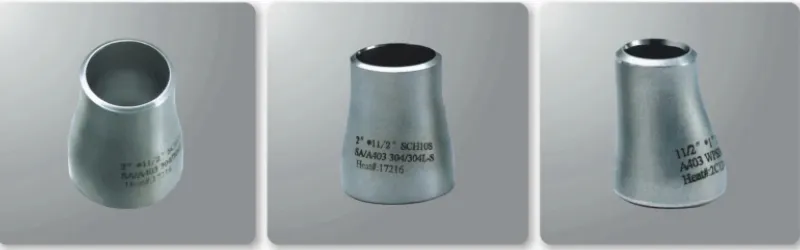

According to shapes, stainless steel reducing tubes are usually divided into stainless steel concentric reducers and stainless steel eccentric reducers.

Stainless steel concentric reducers mean the center of the circle is on the same line.

Stainless steel eccentric reducers mean one side is larger in diameter than the other, creating an offset or eccentric connection.

2. Manufacturing Process

According to the manufacturing process, stainless steel reducing tube is generally divided into welded stainless steel reducing tubes and welded stainless steel reducing tubes.

Seamless stainless steel reducing tube: it is to put the stainless steel pipe into the forming mold, and press or expand along the axial direction of the tube blank. The metal moves along the mold cavity and shrinks into shape.

Welded stainless steel reducing tube: it is made by welding stainless steel plate to form the corresponding reducing pipe fittings.

3. Grade

According to stainless steel grade, it can be divided into stainless steel reducing tubes in different grades, such as 304 stainless steel reducing tubes, 316 stainless steel reducing tubes, 321 stainless steel reducing tubes, etc.

Stainless Steel Reducing Tubes Properties

1. Good Corrosion Resistance

Stainless steel reducing tubes are made from high-quality stainless steel. Therefore, it offers excellent corrosion resistance, making the tube suitable for applications where strength and resistance to harsh environments are required.

2. Great Durability

They usually have a longer service life than conventional reducing tubes, almost more than 30 years.

3. Heat Resistance

They can withstand high temperatures and pressures, making them suitable for a wide range of applications.

4. Various Designs

The dimensions of stainless steel reducing tubes can vary depending on the specific requirements of the project. At Gnee Steel, they are available in various sizes, wall thicknesses, and lengths to meet customers’ demands.

5. Easy Installation

There are various connection methods for reducing stainless steel pipes. Common methods include compression type, union type, push thread type, socket welding type, union flange connection, and welding and traditional connection. All are easy to install.

Besides, the connection joints can be sealed by silicone rubber, nitrile rubber, and EPDM rubber that meet standard requirements.

Stainless Steel Reducing Tube Applications

These tube fittings have been designed specifically for the many demanding applications such as chemical, petroleum, power generating, construction, energy, etc. For example, they can be used in instrumentation, pipe processing, liquid or gas transmission, high pressure, and temperature control systems.

What’s more, it is worth noting that stainless steel reducing tubes are often used in conjunction with stainless steel fittings, such as elbows, tees, reducers, and flanges. These fittings are used to connect and join the different sections of the tubing system.

Overall, stainless steel reducing tubes are versatile components that play a crucial role in various industries, providing a reliable and durable solution for connecting pipes or tubes of different sizes.

Factors to Consider When Choosing Stainless Steel Reducing Tubes

When selecting stainless steel reducing tubes, it is important to consider factors such as material grade, size, wall thickness, and end connections. Choosing the right specifications based on the specific requirements of the application is crucial for your applications. If you have any questions, welcome to contact our technical team for help.