Product Specification, Characteristics, and Applications

1. Stainless steel oval pipes are classified as 304, 316, 321, and 316L depending on the material.

2. It is classified as bright surface treatment or no bright surface treatment based on the surface treatment.

3. It may be classified into industrial, building decoration, food and medical, ship and marine, petrochemical, and so forth.

It can also be categorized based on processing technology and unique application.

The characteristics and applications are as follows:

1. Corrosion resistance: It is resistant to corrosion in both oxidizing and reducing environments, making it a popular choice for chemical processing and other corrosive environments such as heat exchangers, furnaces, petrochemical equipment, conduits, masts, anchor chains, distillation columns, storage tanks, and so on.

2. Heat resistance: Because of its excellent heat resistance, it is appropriate for high-temperature applications such as furnaces, burners, pipelines, and so on.

3. Biocompatibility: It is widely used in the production of medical equipment and instruments such as surgical instruments, acupuncture instruments, other medical care instruments, treadmills, and other fitness equipment because it is non-irritating to human tissues and has excellent biocompatibility.

4. Stainless steel oval pipe can tolerate high temperatures, has excellent creep strength, and can be used continuously at high temperatures without distortion.

5. Because they are easy to maintain, clean, and non-corrosive, they are suited for applications that value cleanliness, such as environmental protection equipment, sewage treatment systems, and so on.

6. Safe and clean: Stainless steel oval pipe fulfills hygiene standards, is difficult for bacteria to grow on, and is completely safe to use. It is widely used in food, medical, and other industries to make spice storage tanks, cutlery, syringes, workstations, and other items.

7. Plasticity: The pipe may be made using a range of processing processes, including as cold drawing, cold rolling, cold bending, and so on, to accommodate a variety of shapes and sizes.

| Item | Stainless Steel Oval Pipe | |

| Standard | ASTM, DIN, GB, or customized size required by customers. | |

| Material | C, Fe, Mo, Mn, Si, N, etc. | |

| Grade | 304, 316, 321, etc. | |

| Size | Wall Thickness | 0.5mm~2.0mm |

| Outer Diameter | 9.5mm~108mm | |

Product Purchase Considerations

1. The elliptical tube is typically pressed with a round tube, and the specifications to be utilized should be determined by the size of the round tube and the size of the elliptical elbow. It should be noted that the size pressed out by the supplier must nearly match the elliptical elbow, or it will not be welded.

2. The thickness should be appropriate: too thin a pipe with stainless steel pipe cannot be squeezed out and is easily deformed; too thick a pipe pressure pipe price will be significantly more, so keep this in mind when creating a budget.

3. The technology of the chosen provider must pass customs, which means that the extruded pipe must be straight, as it cannot be welded if it is not straight.

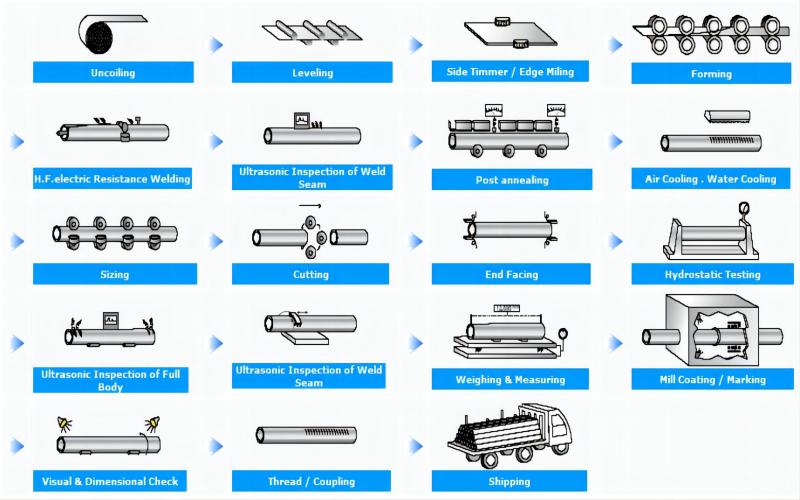

Product Manufacturing Process

1. Raw material selection: Depending on the necessary mechanical, corrosion, and temperature resistance capabilities, manufacturers may use different grades of stainless steel, such as 304 or 316.

2. Tube formation: To create the oval tube from a flat sheet or strip of stainless steel, manufacturers may employ a variety of tube forming techniques such as roll forming, press bending, or rotary drawing.

3. Welding: To combine the two ends of the oval tube and ensure a continuous and smooth surface, manufacturers may employ various welding processes such as TIG or laser welding.

4. Heat treatment: Depending on the desired material qualities, some producers may subject the stainless steel oval tube to heat treatment methods such as annealing or quenching, and tempering to improve mechanical, thermal, or corrosion resistance.

5. Finishing: To obtain the desired look and surface quality of the stainless steel oval pipe, manufacturers may use several finishing procedures such as polishing or satin finishing.

Market Competition and Prospect

The global stainless steel market is predicted to expand as a result of rising demand from industries such as construction, automotive, and chemical processing, as well as the development of new stainless steel grades and applications. The stainless steel market is highly competitive because numerous global and regional competitors offer a diverse range of products and services, including flat items, long products, pipes, and tubes, as well as manufacturing, engineering, and distribution services. Furthermore, the stainless steel industry faces issues such as variable raw material prices, greater competition from low-cost producers in emerging regions, and the need to adapt to changing customer expectations and environmental rules. In terms of the stainless steel industry’s prognosis, there are growth opportunities in rising regions such as Asia Pacific and Latin America, as well as innovative stainless steel uses in industries such as medical devices, renewable energy, and 3D printing.

The Gnee Steel Group is a supply chain firm that combines panel design and processing, pipes and profiles, outdoor landscaping, and overseas small product sales. It was founded in 2008 to be the most competitive supply chain group in the world; since then, we have been committed to achieving that goal with great, consistent, and creative services. The Gnee Steel Group has become the most professional steel supply chain worldwide firm in the Central Plains after many years of hard labor.