What is Stainless Steel I Beam?

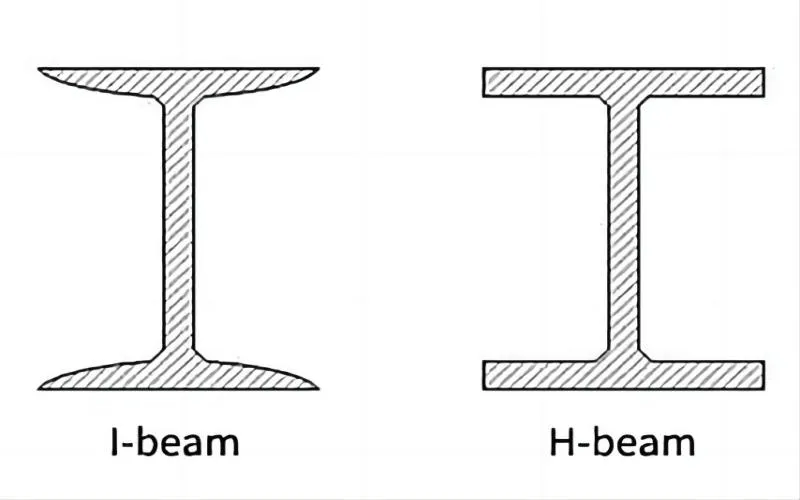

A structural beam having an I or H-shaped cross-section is called a stainless steel I-beam, or stainless steel H-beam. Stainless steel, which is used in its construction, provides exceptional durability and resistance to corrosion. I-beams made of stainless steel are widely utilized in a variety of sectors and settings because of their durability and visual beauty.

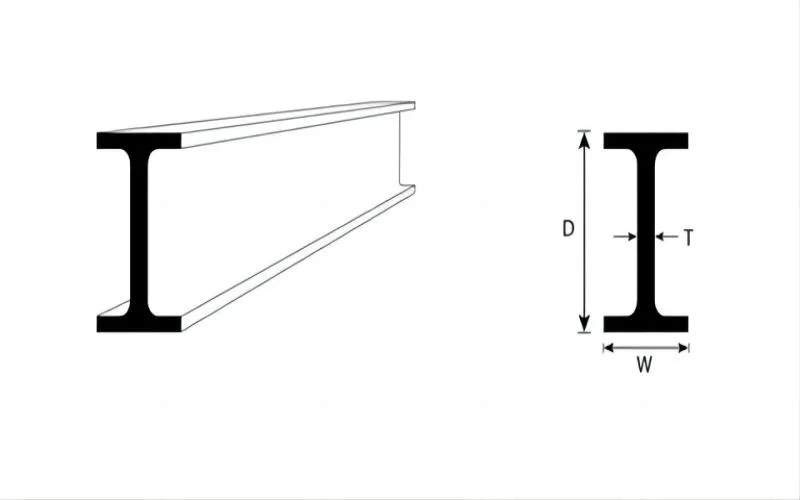

Dimensions and form: Stainless steel I-beams are made up of two horizontal flanges joined by a vertical web, giving them a recognizable I or H shape. Because the flanges are broader than the web, they can support a greater weight. Depending on the particular standard and grade, stainless steel I-beam diameters can change.

Typical parameters: Specific guidelines, like those set forth by EN (European Norms) or ASTM (American Society for Testing and Materials), are followed during the manufacturing process of stainless steel I-beams. The measurements, tolerances, and other characteristics of stainless steel I-beams are specified by these standards.

What Are the Advantages of I-Beam?

A long steel bar with an I-shaped cross-section is called an I-beam, sometimes referred to as a steel beam or Universal Beam in English. There are two types of I-beams: light I-beams and regular I-beams. The steel is sectional and has an I-shaped cross-section. The following are its benefits:

- I-beams can have their length adjusted as needed because they are robust and simple to cut and weld.

- I-beam features a long service life and anti-aging properties. Steel, its primary basic material, has superior impact and wear resistance than other materials, which explains why.

- I-beams are lightweight, simple to assemble and contribute to a quicker construction time. Its unique structure allows it to be lighter while maintaining strength, simplifying handling, and cutting down on construction time.

- The I-beam is in keeping with public aesthetics, has a lovely appearance, and is symmetrical up and down.

- I-beams also have the qualities of thermal insulation, fire retardancy, high magnetic permeability, and insulation.

How to Deal With Rust on I-Beam?

1. To remove rust, use tiny electric or pneumatic machines. This method of removing rust from steel components involves using equipment that is powered by compressed air or electricity to remove rust from steel parts’ surfaces.

2. Shot blasting and rust removal: This technique employs the centrifugal force of the shot head to throw steel shots of a specific size using the high-speed operation of mechanical equipment. To eliminate rust from the steel surface, the components are forcefully collided with the thrown steel bullets.

3. Manual rust removal: To remove rust from steel structural sections, this approach employs wire brushes, emery cloths, scrapers, and other instruments. However, be advised that this approach is ineffective and might not eliminate rust completely enough.

4. Chemical rust removal: To remove oxides from the surface of steel buildings, use a neutral rust remover. New steel structure rust avoidance can be achieved by applying metal coatings and coatings. The coating coating method involves coating the steel’s surface to keep it sealed off from the environment and to stop corrosion. The three primary building procedures are topcoat application, primer application, and surface rust removal.

Applications of Stainless Steel I Beam

- Architecture and construction: For structural support in the form of beams, columns, and frames, stainless steel I-beams are utilized in construction projects. They give infrastructure and buildings durability, strength, and stability.

- Industrial and manufacturing: I-beams made of stainless steel are used in factories, warehouses, and manufacturing facilities. They support equipment frames, conveyor systems, and large machines.

- Marine and offshore: Because stainless steel I-beams resist corrosion, they are extensively utilized in the marine and offshore sectors. Shipbuilding, offshore platforms, and other maritime structures are among the uses for them.

- Chemical and petrochemical facilities: I-beams made of stainless steel are appropriate for use in refineries, petrochemical facilities, and chemical processing plants. They are resistant to high temperatures and caustic substances.

- Food processing and pharmaceuticals: Because of their corrosion resistance and hygienic qualities, stainless steel I-beams are employed in the food processing and pharmaceutical industries. They are employed in support structures, platforms, and equipment frames.

- Infrastructure and bridges: Overpasses, bridges, and other infrastructure projects are built using stainless steel I-beams. They give these buildings strength and the capacity to support loads.

- Energy and power generation: Power plants, renewable energy initiatives, and other energy generation facilities employ stainless steel I-beams. They give machinery, turbines, and generators structural support.

- Aerospace and aviation: These two sectors use stainless steel I-beams in their operations. They are employed in the building of landing gear components, support structures, and aircraft frames.