What Is Stainless Steel Concentric Reducer?

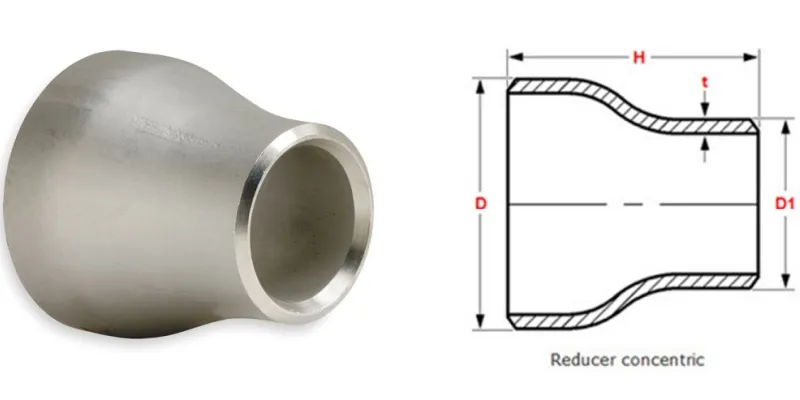

Stainless steel concentric reducer, as its name implies, reduces in diameter towards the center thus forming a conical cylinder. Therefore, it is also known as the tapered expansion pipe or symmetrical reducer, which is used to connect two stainless steel pipes of different sizes in piping systems.

It is called “concentric” because the reduction in diameter is uniform and centered around the axis of the fitting. The reducer has a larger diameter on one end and a smaller diameter on the other, allowing for a smooth transition of flow between the two pipes.

Function of Stainless Steel Concentric Reducer

1. When the flow rate of fluid in a pipeline increases or decreases but the flow speed does not change, the concentric reducer can be used.

2. Concentric reducer can be used at the inlet of the pump to prevent cavitation.

3. To cooperate with the joints of instruments, flow meters, and regulating valves, concentric reducers can be used.

Stainless Steel Concentric Reducer Dimensions

| Raw Material | stainless steel |

| Standard | JIS, AISI, ASTM, DIN, SUS, EN, GB |

| Certifications | ISO 9001, SGS, BV, GB |

| Grades | 304, 310, 316, 321, 410, 420, etc |

| Thickness | 1.5 – 26 mm or as customer’s requirements |

| Supply Forms | seamless stainless steel concentric reducers, welded stainless steel concentric reducers |

| Delivery time | within 7-10 working days |

Stainless Steel Concentric Reducer Properties

– Good corrosion resistance. Made of stainless steel, these fittings boast great resistance to corrosion and rust.

– High strength. It has higher toughness than conventional carbon or steel concentric reducers.

– East to install and maintain. This makes them the most economical solution for piping systems.

– Versatility. These stainless steel concentric reducers are well-suited for a wide range of applications, ranging from food processing to chemical industries.

Stainless Steel Concentric Reducer Applications

Stainless steel concentric reducers are chosen by installers because of their very good fluid kinetics. Therefore, they are often used inline on a vertical flow application, or if laid horizontally, as an increase. However, it is not recommended to use concentric reducers in horizontal applications where pooling may occur. In such cases, stainless steel eccentric reducer, which lays flat on one side, is preferable.

Nowadays, stainless steel concentric reducers are commonly used in various industries, including food and beverage, water conservancy, pharmaceutical, chemical, oil and gas, energy, etc.

Stainless Steel Concentric Reducer Installation

When installing stainless steel concentric reducers, here are some steps to comply with:

First, one must cut the pipes to the desired length.

Next, apply sealant or thread tape to the threads, and tighten the connections with a trusty wrench.

Finally, It is imperative to ensure a secure and leak-free installation, so as to avoid any potential issues within the piping system.

Stainless Steel Concentric Reducer Maintenance

For proper maintenance, regularly inspect the reducer for corrosion or damage and clean it with a mild detergent and a soft cloth. Furthermore, it is essential to ensure that the piping system is adequately supported to prevent undue stress on the reducer. If you have some other questions, Gnee Steel, a professional stainless steel pipe fitting expert, can be you good helper.