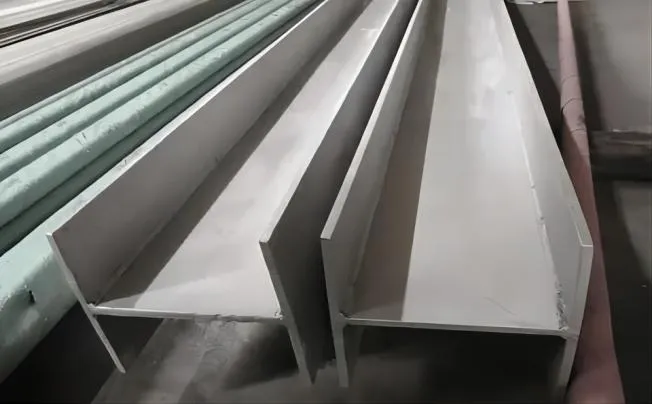

What is Hot Rolled Steel H Beam?

A structural beam with a cross-sectional shape of a “H” is called a hot-rolled steel H beam. Because of its strength and load-bearing capabilities, it is frequently employed in industrial and construction applications. To create hot-rolled steel H beams, a steel billet is heated and then fed through a number of rolling mills to give it the correct size and shape. They can be tailored to match the needs of a particular project and come in a variety of sizes.

H beams made of hot-rolled steel are widely utilized in equipment, construction, bridges, and other structural applications. Although they are comparable to I beams, both types are frequently combined to determine the best weight-bearing arrangement. Depending on the producer and the needs of the project, hot-rolled steel H beams can have different dimensions, grades, and specifications.

What distinguishes a welded h beam from a hot-rolled h beam?

A welded beam is a constructed section created on-site by joining plates, whereas a hot-rolled beam is, as the name implies, one single piece of metal formed into that shape while it is hot. Cutting strips of appropriate thickness into a desired width and joining the waist and edge in a continuous welding machine is the process of welding an H-beam. Some of the drawbacks of welded H-section steel are its high metal consumption, low production cost, and challenges in guaranteeing consistent product performance.

Thus, rolling is the primary method used in the manufacture of H-beams. Hot-rolled H-beam with exceptional qualities, high efficiency, low consumption, and cheap cost is made using a near-net-shaped continuous casting blank and a four-roll universal rolling technique. It offers significant benefits in terms of raising the calibre of iron and steel materials and generating revenue.

When the manufacturer does not have the needed size of beam in stock, or when the economy dictates otherwise, we typically use a built-up section.

Additionally, you can alter a built-up section to suit your specifications, including thickness, web depth, and flange width; however, this can only be done for really big orders when it comes to hot-rolled sections.

Applications of Hot Rolled Steel H Beam

- Construction: For structural support in buildings, bridges, and infrastructure projects, hot-rolled steel H beams are extensively utilized in the construction sector. They give the sturdiness and strength of the structure.

- Industrial structures: Manufacturing plants, warehouses, and factories are just a few examples of the types of buildings that are built using H beams. They can sustain large weights and offer a sturdy structure for machinery and equipment.

- Bridges: Because of their great strength and capacity to support loads, hot-rolled steel H beams are frequently utilized in the construction of bridges. They can span great distances and give the bridge deck structural support.

- Skyscrapers: When constructing tall buildings and skyscrapers, H beams are frequently employed as the main structural component. They can sustain the weight of several stories and endure earthquake and wind affects thanks to their strength and stability.

- Platforms and mezzanines: In commercial and industrial contexts, raised platforms and mezzanines are constructed using H beams. They offer a strong foundation for equipment installations, storage spaces, and pathways.

- Support structures: H beams are employed in many different contexts as support columns or beams, including the support of canopies, awnings, and roof structures.

- Trailers and transportation: To provide structural stability and support, H beams are used in the building of trailers and transportation equipment.

- Support for housing: H beams can be utilized for load-bearing walls, floor joists, and roof trusses in residential construction.

The difference between hot rolling and cold rolling

Hot rolling: The process of rolling steel at temperatures over its recrystallization temperature (generally above 1700°F or 926°C) is known as hot rolling. To shape the steel into the proper shape, it is heated and then sent through a series of rolling mills. Because hot rolling raises the temperature of the steel, it can be formed and shaped more easily and fast.

Conversely, cold rolling is a procedure carried out at or close to room temperature. Following the first round of hot rolling, the steel is allowed to cool before undergoing additional processing in cold reduction mills. In cold rolling, the steel is run through a sequence of rollers at room temperature in order to attain the required surface smoothness, thickness, and shape. The mechanical qualities, surface smoothness, and dimensional precision of steel can all be enhanced by cold rolling.

Impact on properties: The steel’s properties may be impacted by the various rolling techniques. Because of the high temperatures involved, hot-rolled steel typically has a coarser surface finish and may have a scaled surface. In general, it is less accurate in terms of dimensions. In contrast, cold-rolled steel offers superior dimensional precision and a smoother surface finish. Better mechanical qualities, such as increased tensile strength, can also be attributed to the work hardening that takes place during the cold rolling process.

Applications: Hot-rolled steel is frequently used for sheet metal, railway tracks and structural components—applications where exact forms and tolerances are not necessary. Applications like automotive parts, appliances, and metal furniture that demand greater precision and a smoother surface generally employ cold-rolled steel.