What is Stainless Steel Foil?

A thin sheet or strip of stainless steel, known as stainless steel foil, is frequently utilized in a variety of commercial and industrial applications.

Composition: The main component of stainless steel foil is stainless steel, an alloy consisting of iron, chromium, and other components. The most commonly used stainless steel grades for making foil are 304 and 316L.

Properties: High strength, resistance to corrosion, and heat resistance are just a few of the advantageous qualities that stainless steel foil possesses. It also has good formability and is non-magnetic.

Surface Finishes: To satisfy diverse needs, stainless steel foil is offered in a range of surface finishes. Chromium is added to stainless steel to create an imperceptible yet protective coating that aids in the foil’s resistance to corrosion and rust.

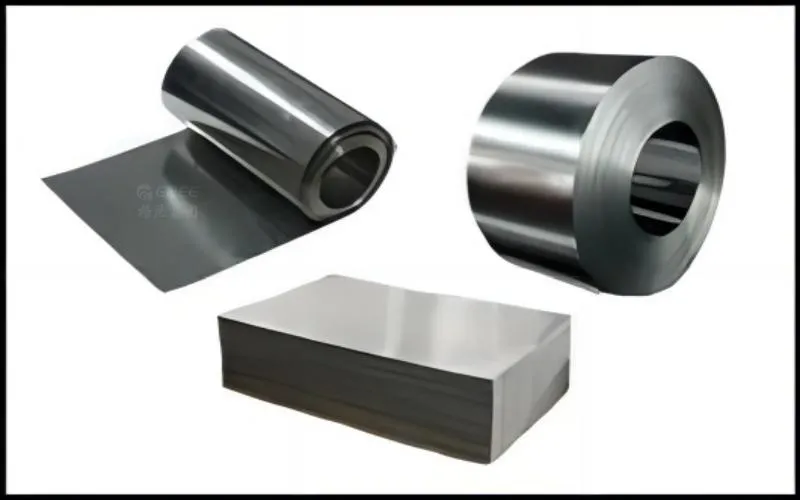

Width and Thickness: Depending on the intended use, stainless steel foil comes in various widths and thicknesses. It can range from thicker sheets to extremely thin foils (0.002 inches thick, for example).

Availability: A variety of wholesalers and providers of metalworking products offer stainless steel foil for purchase online.

Properties: High strength, resistance to corrosion, and heat resistance are just a few of the advantageous qualities that stainless steel foil possesses. It also has good formability and is non-magnetic.

Surface Finishes: To satisfy diverse needs, stainless steel foil is offered in a range of surface finishes. Chromium is added to stainless steel to create an imperceptible yet protective coating that aids in the foil’s resistance to corrosion and rust.

Width and Thickness: Depending on the intended use, stainless steel foil comes in various widths and thicknesses. It can range from thicker sheets to extremely thin foils (0.002 inches thick, for example).

What is 440 Stainless Steel Foil?

440 stainless steel foil refers to a specific type of stainless steel foil made from the 440 series of stainless steel alloys. The 440 series is known for its high carbon content, which contributes to its excellent hardness and wear resistance after heat treatment. Composition: 440 stainless steel foil is primarily composed of iron, chromium, and a high carbon content. The most common grade in the 440 series is 440C, which contains the highest carbon content among the 440 alloys.

Properties: After heat treatment, 440 stainless steel foil has remarkable hardness, wear resistance, and strength. When hardened, it has good corrosion resistance and is magnetic under all circumstances.

Applications: 440 stainless steel foil is frequently utilized in parts that call for exceptional strength and endurance because of its high hardness and wear resistance. Surgical devices, cutting tools, ball bearings, valve components, and specific kinds of blades are a few examples of common applications.

Availability: A variety of wholesalers and distributors specializing in stainless steel products provide 440 stainless steel foil for purchase. It can be found in various widths and thicknesses to meet the demands of a particular application.

Applications of 440 Stainless Steel Foil

Owing to its desirable properties, 440 stainless steel foil finds a variety of uses. Here are some common uses for 440 stainless steel foil:

1. Knife Blades: Due to their hardness, wear resistance, and corrosion resistance, 440 stainless steel foil is widely used in the production of high-quality knife blades. Its suitability for kitchen cutlery and other types of knives is enhanced by these properties.

2. Valve Components: Owing to its high strength and moderate corrosion resistance, 440 stainless steel foil is a good choice for valve components because it can function dependably under demanding conditions.

3. Ball Bearings: Ball bearings are made using 440 stainless steel foil. Under heavy loads and high rotational speeds, bearings can operate smoothly and effectively thanks to their hardness and wear resistance.

4. Surgical tools: 440 stainless steel foil is suited for surgical tools due to its strength and resistance to corrosion. It is employed in the manufacturing of numerous surgical instruments and apparatus.

5. Mold and Dies: The manufacture of molds and dies uses 440 stainless steel foil. It is appropriate for shaping and forming materials in a variety of industries due to its hardness and wear resistance.

6. Other Applications: 440 stainless steel foil is also utilized in textile components, rolling element bearings, measurement equipment, and other applications where a blend of strength, corrosion resistance, and wear resistance is needed.