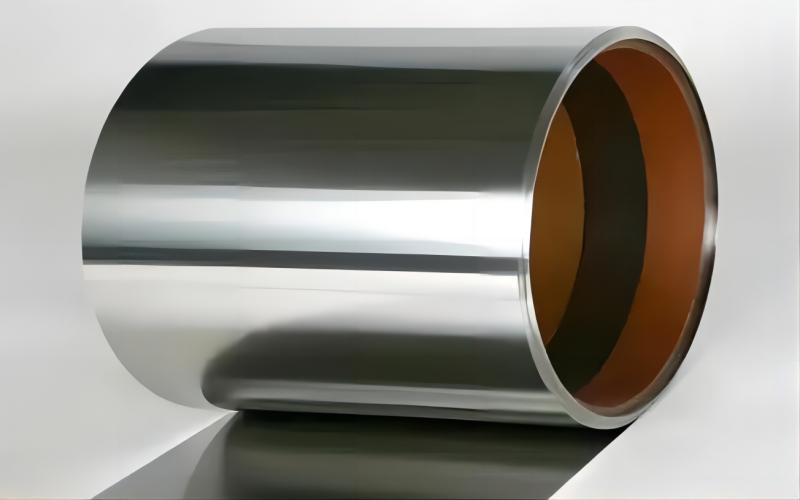

What is 410 Stainless Steel Foil?

A typical stainless steel material used in many different applications is 410 stainless steel foil. The martensitic stainless steel alloy known as 410 has a high degree of strength, hardness, and resistance to corrosion. It is resistant to corrosion in steam, many moderate chemical conditions, and mild atmospheres since it contains at least 11.5% chromium. 410 stainless steel foil is offered by vendors and manufacturers who specialize in stainless steel products. It comes in sheet, strip, and wire forms.

What is Stainless Steel Foil?

A thin sheet or strip of stainless steel that is usually less than 0.25mm (0.010 inches) thick is referred to as stainless steel foil. The alloy used to make it, stainless steel, is mostly made up of iron, chromium, and other metals like nickel and molybdenum. The strength, durability, and resistance to corrosion of stainless steel foil are well known.

Applications of 410 Stainless Steel Foil

1. Cutlery and culinary utensils: The manufacturing of knife blades, scissors, and other culinary utensils frequently uses 410 stainless steel foil. It is appropriate for various applications due to its strength, hardness, and resistance to corrosion.

2. Industrial Components: It is used in a variety of industrial components, including pumps, pipe fittings, valves, and parts for equipment used in chemical processing and petroleum refining. These tough industrial settings are a good fit for 410 stainless steel because of its strength and resistance to corrosion.

3. Automotive Components: Exhaust systems, catalytic converters, and other components are among the uses for 410 stainless steel foil in the automotive sector. It is appropriate for various automotive applications due to its resistance to corrosion and high temperatures.

4. Firearms: Because of its strength and resistance to corrosion, it is utilized in weapon barrels and other components.

5. Decorative Applications: When a smooth decorative finish is not necessary, 410 stainless steel foil may be utilized. It can be applied as decorative trim or for other uses where strength and resistance to corrosion are crucial.

What is the Difference Between 304 Stainless Steel and 410 Stainless Steel?

Due to their widespread usage, 304 and 410 stainless steel are two relatively common types of stainless steel. What distinguishes these two stainless steel materials from one another, then? Their chemical makeup, mechanical characteristics, resistance to corrosion, and relevant sectors are described below. Let us delve deeper into each of the four aspects.

chemical composition

Austenitic stainless steel, or 304 stainless steel, is highly malleable and resistant to corrosion. Its primary constituents are nickel (Ni) 8%–10.5%, chromium (Cr) 18%–20%, and trace amounts of carbon (C) and manganese (Mn) up to 2% and 0.08%, respectively.

The martensitic stainless steel known as 410 has a reasonably high strength and hardness but a comparatively low corrosion resistance. Main constituents include 11.5%–13.5% chromium (Cr), 0.08%–0.15% carbon (C), and a trace quantity of nickel (Ni), which is mostly made up of molybdenum (Mo) with a maximum of 0.6% nickel and a maximum of 0.75% molybdenum.

Mechanical behavior

While 410 stainless steel has high tensile strength and hardness but low elongation, meaning its toughness is relatively low, 304 stainless steel has high elongation and plasticity, making it more suited for processing, forming, or bending.

Corrosion resistance

Because 304 stainless steel has more nickel and molybdenum than other stainless steel, it is more corrosion resistant, particularly when exposed to corrosive media. In contrast, 410 stainless steel contains less nickel and molybdenum than other stainless steel, making it less corrosion-resistant overall.

Applicable fields

Pressure vessels, medical equipment, food processing equipment, chemical equipment, and other fields can benefit from the good corrosion resistance and plasticity of stainless steel 304; on the other hand, industries requiring wear resistance and strength, like knives, can benefit from the high strength and hardness of stainless steel 410. 410 stainless steel is not appropriate for applications requiring strong corrosion resistance in industries like bearings and valves.