Products Description

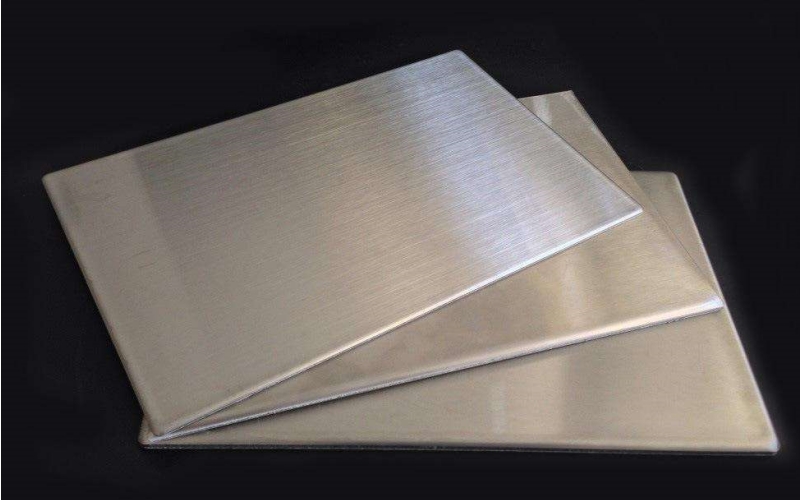

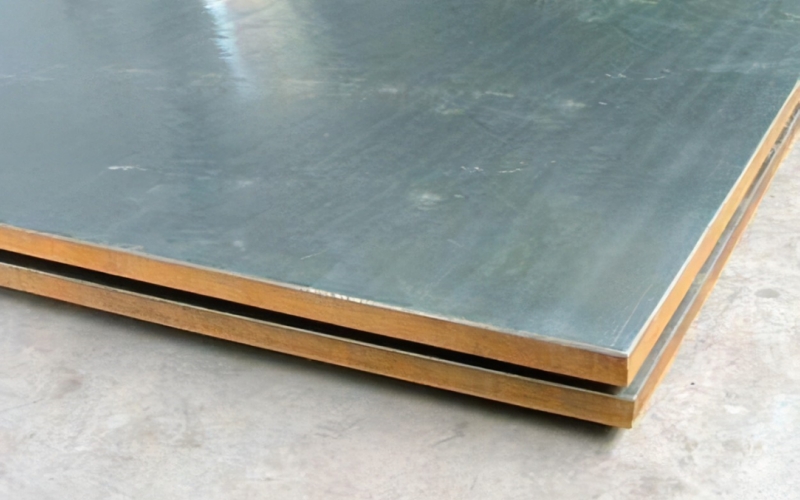

347 Stainless steel clad plate is usually made of a thin 347 stainless steel plate and thick carbon steel plate and is generally manufactured by roll bonding and explosion welding. It belongs to both structural material and functional materials. Structural steel means the base material, usually using carbon steel or other low alloy steel to ensure toughness and strength. Functional steel is the cladding material, which gives corrosion resistance, heat resistance, and a bright surface to the stainless steel clad plate.

Grade 347 Stainless Steel

Type 347 is classed as stabilized stainless steel by the addition of columbium and tantalum. These elements can well stabilize the steel and eliminate carbide precipitation which subsequently causes intergranular corrosion following exposure to temperatures in the chromium carbide precipitation range from 800 to 1500°F (427 to 816°C). Besides, it also offers excellent heat and corrosion resistance, excellent forming and welding qualities, and excellent toughness even at cryogenic temperatures.

Generally speaking, grade 347 is similar to grade 321 stainless steel and is often regarded as a stabilized alternative to grade 304.

Grade 347 Stainless Steel Chemical Composition

| C | Si | Mn | P | S | Cr | Mo | Ni | N | Cb | Fe |

| 0.08

max |

1.0 max | 2.0 max | 0.045 max | 0.03 max | 17-20 | – | 9-13 | – | 10xC-1.10 | 62.74 min |

Grade 347 Stainless Steel Mechanical Properties

| Density | Melting Point | Tensile Strength | Elongation |

| 8.0 g/cm3 | 1454 ℃(2650 ℉) | Psi-75000, Mpa-205 | 35% |

Grade 347 Stainless Steel Equivalent Grades

| China | GB-06Cr18Ni11Nb, CNS347 (Taiwan) |

| America | UNS S34700, ASTM347 |

| Japan (JIS) | SUS347 |

| India (IS) | 04Cr18Ni10Nb40 |

| European (BS EN) | 1.4550 |

| Korea (KS) | STS347 |

| Australia (AS) | 347 |

Production Fabrication

There are two main methods for industrial production of stainless steel clad plates, including 310, 316, and 347 stainless steel grades. They are explosive cladding and hot rolled cladding. Let’s give a brief overview of them now.

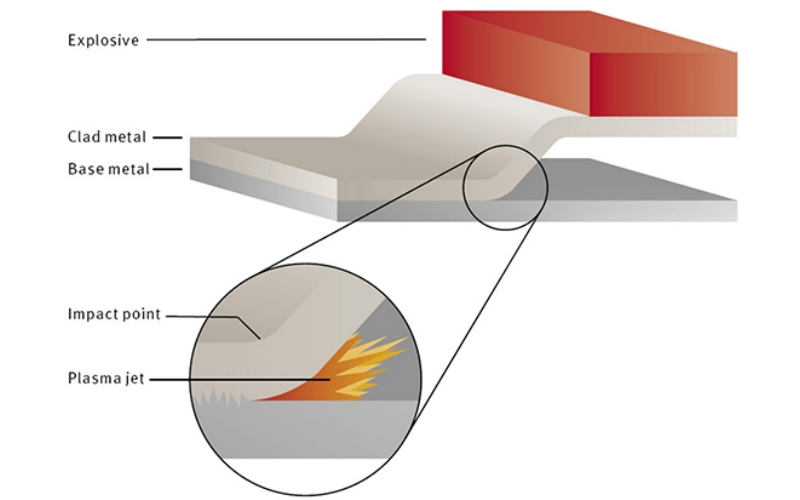

1. Explosion Cladding

Explosive cladding is a type of bonding technology that defines a trinity of pressure selection, flame transmission, and diffusion explosion with explosives as energy. It uses the energy of explosive detonation to do work on the stainless metal clad layer so that the clad layer and the base layer will have a violent collision in high-speed movement. And then the interface will produce locally high temperature and the metal material will have plastic deformation, thus having a close combination between the clad layer and the base layer. Sometimes, annealing treatment can be carried out after explosive recombination, which can further improve the welding quality.

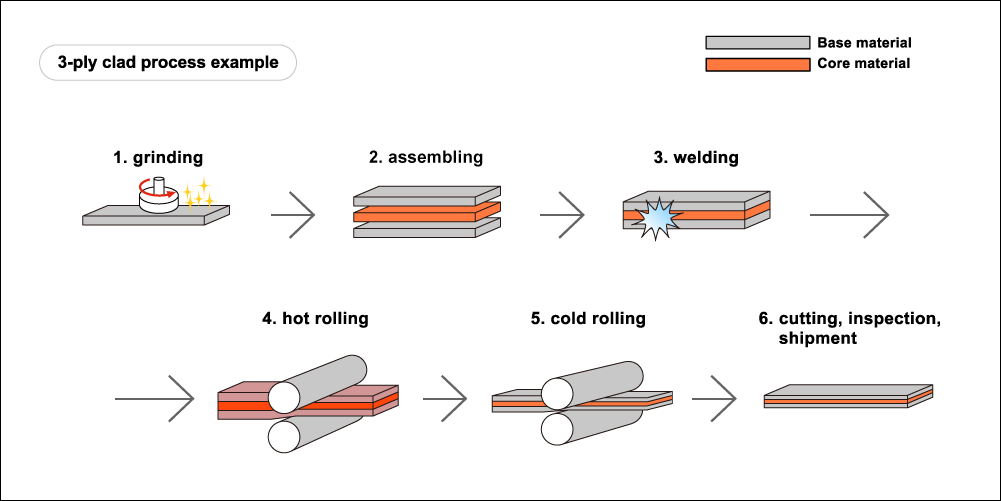

2. Rolling Cladding

Compare with the former, the rolling cladding has faster production speed, firmer bonding, lower cost, and greener properties. When the surfaces of two metals are cleaned in a physically pure state, it is often made by either hot rolling or cold rolling.

The hot rolling process is to achieve a continuous metallurgical bonding by a high degree of interatomic diffusion and plastic deformation through a large-scale rolling mill. Sometimes, the hot-rolling process can be conducted after the exposure of the stainless clad plate to explosion cladding.

The cold rolling process means it uses the cooling HR stainless steel clad plates as the substrate to process. The steps include annealing, pickling, cold rolling, intermediate annealing, pickling (or bright annealing), tension leveling, etc. The surface of this kind reaches the surface quality of the same series of stainless steel plates, and the yield strength is better than that of the same grade of stainless steel plates.

Product Specifications

| Raw Material | base metal: low-alloy steel or carbon steel (Q235B、Q345R、Q355、Q245R、20#、40#…)

cladding metal: stainless steel (304, 304L, 310, 310S, 316, 321, 318, 410S, 420, 904L…) |

| Grade | 347 |

| Standard | ASTM, AISI, DIN, EN, GB, JIS |

| Thickness | base material thickness: 3 – 50 mm

cladding material thickness: 0.5 – 5 mm cladding thickness: 1.5 – 5 mm |

| Width | 100 – 1200 mm |

| Length | 500 – 15000 mm |

| Shape | rectangular, square, round, or as required |

| Production Method | explosive cladding, hot/cold rolling |

| Surface | NO.1, 2B, BA, 4K, 8K, HL, NO.4, annealed, pickled, polished, patterned, etc |

| Processing Services | cutting, shearing, welding, leveling, rolling, punching, bending, etc |

| Package | standard export seaworthy package or as required |

*Notice: Material and thickness can be combined freely to meet the needs of different users.

Products Features

347 Stainless steel composite plate has many benefits you can see from the following aspects:

1. Excellent Corrosion & Heat Resistance

Firstly, the stainless steel material makes sure its high anti-corrosion performance than conventional steel. Secondly, due to the addition of columbium, it also has resistance to intergranular corrosion after exposure to temperatures in the chromium carbide precipitation range of 800–1500°F (427–816°C). Besides that, it also has better oxidation resistance, heat resistance, and creep and stress rupture properties than grade 304.

2. High Thermal Conductivity & Yield Strength

The 347 stainless steel composite plate has high thermal conductivity, which is 3 times that of pure stainless steel plates. In view of the yield strength, the yield strength of the pure stainless steel plate is 190MPa while the yield strength of 347 stainless steel clad plate is above 280MPa.

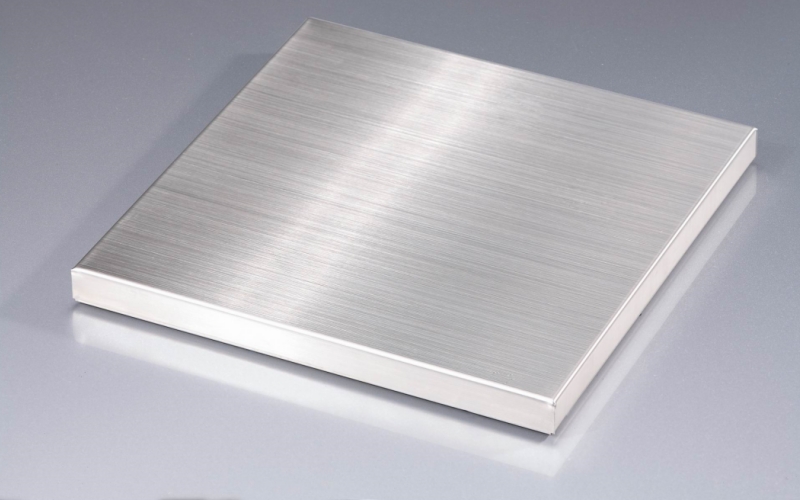

3. Elegant Surface

The appearance of the 347 stainless steel clad plate is simple, bright, and glossy, which is the same as that of pure stainless steel plate. What’s more, it is essentially non-magnetic in nature.

4. Firm Bonding

It will form a strong and solid metallurgical combination between carbon steel and stainless steel with high temperature and high pressure.

5. Good Processing Performance

Grade 347 is known for being suitable for all common welding techniques as well as hot and cold working. However, when heat treating, the metal must be heated to temperatures in the range of 2100 to 2250°F. This is due to the inability of 347 to work harden under heat treatment. While in cold working conditions, it can carry out various processing such as cold bending, cutting, welding, punching, and so on.

6. Cost-efficient Solution

It can be embodied in the following aspects:

Firstly, as a resource-saving product, it can reduce the consumption of precious metals by 70–80 % and significantly reduce the project cost by 30–50 %. This realizes the perfect combination of low cost and high performance, thus having vast social benefits.

Secondly, as a modification of grade 304 stainless steel, 347 stainless steel is similar to type 321 stainless steel in that both are specifically developed for repeated intermittent exposure to application temperatures above 800°F and up to 1650°F and for corrosion resistance.

Product Applications

Due to its complex chemical composition and excellent performance, 347 stainless steel clad plate has been widely used in petroleum, chemistry, water conservancy, electric power, automobiles, construction, and other high-temperature industries. Applications can be found in:

1. Making ships, boilers, pressure vessels, furnace heating elements, home appliances, steel structures, traffic profiles, fasteners, aircraft collector rings and exhaust stacks, storage tanks, large engine mufflers, jet engine parts, etc.

2. Food and medical equipment, heavy wall welded equipment, paper-making equipment, electric equipment, chemical production equipment, etc.

3. Manufacturing in the form of 347 stainless steel sheets, tubes, pipes, coils, profiles, etc.

4. Public uses include heat exchangers, steam service, surface modification and repair, gaskets, annealing box covers, car and ship luggage racks, reactor components, and decorative material.

*Precautions:

1. Grade 347 stainless steel cladding plate does not perform well in chloride solutions, even in small concentrations, or in sulfuric acid.

2. The plate should be considered for applications requiring intermittent heating between 800 ℉(427 ℃) and 1650 ℉ (899 ℃) or for welding under conditions that prevent a post-weld anneal.

347 Stainless Clad Plate Manufacturer, Supplier, and Exporter

Gnee Group is a leading stockholder, supplier, and exporter of stainless steel clad plates, including 301, 316, and 347 grades. Since starting commercial production of stainless steel, we have been meeting stringent customer requirements for a wide range of applications. We are confident you too will find Gnee’s stainless-clad steel plate and stainless steel products to be highly satisfactory in every respect. Come to get a free quote from us now!