Product Characteristics and Applications

1. Because 321 stainless steel square tube resists corrosion and high temperatures well, it is frequently used in the petrochemical industry for things like reactors, pipeline systems, oil and gas pipelines, wellhead devices, petrochemical equipment, etc. It is possible to maintain good strength and oxidation resistance in the aforementioned high temperature, strong acid, strong alkali, and other corrosive environments. In particular, it is possible to resist welding in these conditions and high temperatures when intergranular corrosion is more likely to occur. Additionally, it is frequently employed in the production of equipment such as cooling towers, condensers, and heat exchanger tubes that can handle corrosive and high-temperature media.

2. Due to the stable element of titanium’s addition, high-temperature furnace tubes, heaters, furnaces, and other high-temperature process equipment are frequently made of titanium due to their comparatively good mechanical qualities and welding performance. It can maintain its high strength and stability at the aforementioned high temperature, and intergranular corrosion cannot easily happen while welding.

3. Its oxidation resistance is also relatively good. It is frequently used in high-temperature furnace tubes, heaters, furnaces, and other high-temperature process equipment. In a high-temperature environment, it can form a stable oxide surface layer, which prevents further oxidation and corrosion and extends the service life. Additionally, 321 stainless steel square pipe is non-toxic, odorless, and won’t produce pollutants, which satisfies the criteria for health standards. As a result, it is frequently used in the production of medical and food processing equipment, including pipelines for food delivery, pharmaceuticals, and surgical instruments.

Product Specification of 321 Stainless Steel Square Tube

| Item | 321 Stainless Steel Square Tube

|

|

| Standard | ASTM, DIN, GB, or customized size required by customers | |

| Material | C, Fe, Mo, Mn, Si, N, etc. | |

| Type | hot rolled and cold rolled | |

| Size | Wall Thickness | 0.5~6mm |

| Outer Diameter | 3mm~300mm | |

What is the difference between 304 and 321 stainless steel?

The fundamental distinction between stainless steel types 304 and 321 is that while 321 contains titanium, 304 does not. Ti can prolong stainless steel’s service life at high temperatures by preventing stainless steel sensitization. In other words, 321 stainless steel is more appropriate than 304 stainless steel in high-temperature environments. With very minor changes in chemical composition, austenitic stainless steels 304 and 321 have remarkably comparable appearances and physical characteristics. First of all, 321 stainless steel requires a trace amount of titanium (Ti) (according to ASTM A182-2008 standard, its Ti content should not be less than 5 times the carbon (C) content, but not more than 0.7%, Second, there are modest variations in the criteria for nickel (Ni) content, with 304 having requirements between 8% and 11% and 321 having requirements between 9% and 12%. Third, there are different chromium (Cr) content specifications, with 304 requiring between 18% and 20% and 321 requiring between 17% and 19%.

And what distinguishes 316 stainless steel from 321? 201 stainless steel is the most economical type of stainless steel, but it is also the easiest to rust; 304 stainless steel is the most popular and commonly used type of stainless steel, but it is also the most expensive; The price of 316 stainless steel, an imported material utilized in various high-end gear for the food industry, aerospace, and other industries, is exorbitant. 316L is the second austenitic stainless steel after 304 stainless steel with a wide range of applications; it is distinguished by the addition of 2-3% molybdenum, excellent pitting corrosion resistance, acid and alkali resistance, and high-temperature resistance. 321 is based on 304 stainless steel and adds titanium elements; it is an austenitic stainless steel.

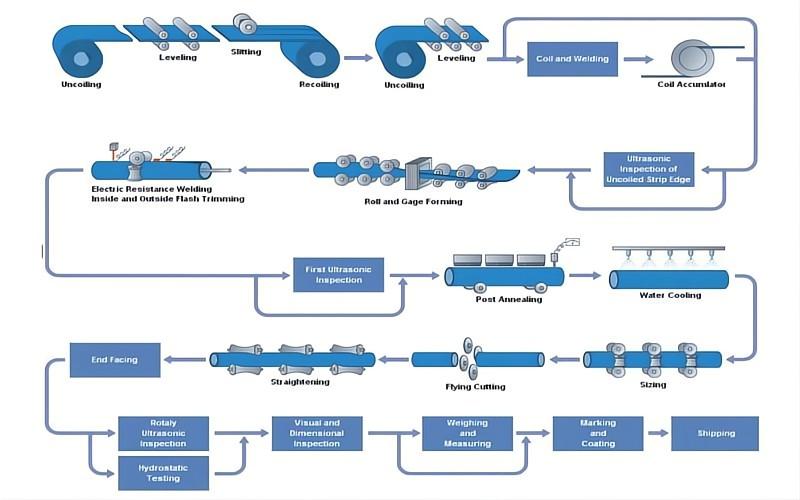

Manufacturing Process

Material preparation: 321 stainless steel square tube is selected as raw material and cut into corresponding sizes according to design requirements.

Bending forming: The plate is bent to make it square or rectangular. It can be bent according to actual needs by cold bending, hot bending, or mechanical bending.

Welding: Bend-formed stainless steel plates are welded to join adjacent edges together. Common welding methods are TIG (tungsten argon arc welding), MIG (metal inert gas shielded welding), resistance welding, etc.

Polishing and finishing: Welded joints are polished and surface treated to make them flat, and smooth, and improve their aesthetics and corrosion resistance.

Dimensional and quality inspection: Dimensional measurement and quality inspection of the manufactured square tube to ensure that it meets the design requirements and relevant standards.

Packing and shipping: Qualified square tubes are packed to protect their surfaces from damage, and delivered or stored at the factory.

Quality Control

The manufacturing of raw materials, including their chemical composition, physical characteristics, material certification, etc., must first be properly regulated to guarantee that they meet all applicable norms and requirements. To guarantee the products’ dimensional accuracy, functionality, and surface quality, the production process—including heating, rolling, piercing, cold drawing, and annealing—should be managed and monitored. Thirdly, to make sure that the product complies with the required size range and composition criteria and is free of evident flaws and surface damage, dimensions and visual examination as well as chemical composition analysis are crucial. To prevent product damage, deformation, or contamination as well as to ensure that they are kept in good condition during transit and storage, regulate and supervise the delivery and packaging process.

Market Competition and Prospect

As the need for steel has increased, numerous domestic manufacturing companies have steadily increased their market share both domestically and abroad. Additionally, they have traveled abroad to establish strategic partnerships with other reliable international businesses. Several nations and regions, including the US, South Korea, Australia, South Africa, and Southeast Asia, receive their products for shipment.

The market for 321 stainless steel square tubes is highly competitive, and customers primarily look at the product’s performance, price, and quality.

Currently, stainless steel is growing in popularity as a material. Square stainless steel tube producers are doing well at home and abroad, which helps the local, national, and international economies grow.

Gnee Steel Group is a supply chain enterprise integrating the design and processing of panels, pipes, profiles, outdoor landscaping, and the sales of international small products. It was established in 2008 with a vision to be the most competitive supply chain group in the global; ever since then, we have always been dedicated to fulfilling that vision with excellent, consistent, and innovative services. After several years of hard work, Gnee Steel Group has become the most professional steel supply chain international enterprise in the Central Plains.