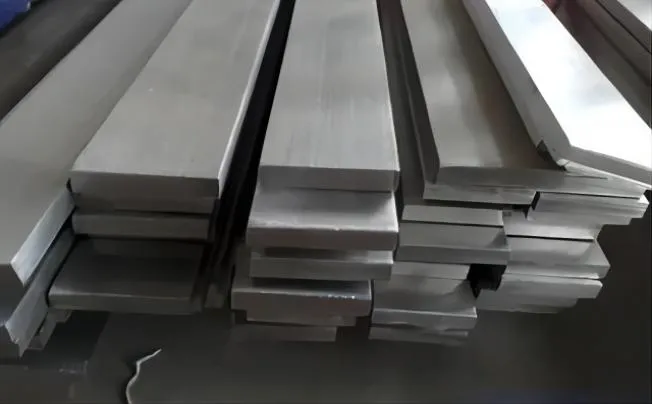

What is stainless flat steel?

Stainless steel flat steel is a versatile steel product with a rectangular shape that is frequently utilized in a variety of industrial and construction applications. True Bar and Sheared and Edge Bar are the two variations that are offered. Sheared and edge bars are cut from a stainless steel coil, and true bars are rolled to the required thickness.

True Bar is appropriate for applications requiring great accuracy because of its precise dimensions and tolerances. However, because of the cutting process, sheared and edge bars may have significantly less exact measurements.

Stainless steel flat steel is very strong, resistant to corrosion, and workable on-site. It is frequently employed in outdoor or maritime applications, machinery, and buildings.

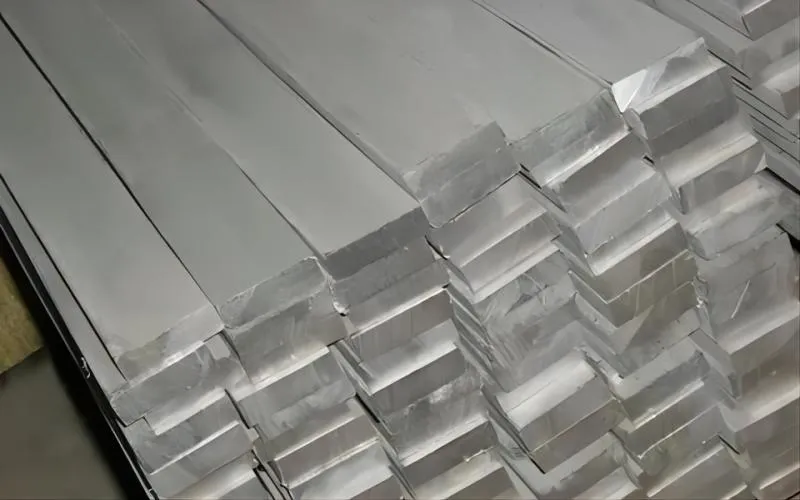

What is 310s stainless flat steel?

Austenitic temperature-resistant stainless steel 310/310S has improved rust resistance at mild cycle factors up to 2000ºF. Due to its extremely high nickel and chromium content, this steel is more resistant to corrosion, has a higher resistance to metabolism, and conserves a larger percentage of energy at room temperature than typical austenitic alloys like Type 304.

310 stainless steel is a popular choice for applications requiring resistance to rust and low magnetic permeability at -450°F. It is also highly durable. Increased chromium concentration gives these grades very good resistance to water corrosion in addition to improving high-temperature performance. It is fairly similar to Grade 316, with a PRE of about 25 and a saltwater resistance of about 22°C. In hot conditions, they are well-resistant to oxidation and carburization. able to withstand molten nitrates and fuming nitric acid up to 425°C at normal temperature.

310S stainless steel is an alloy of austenitic stainless steel with elevated concentrations of nickel and chromium. In comparison to other grades of stainless steel, it also contains less carbon, which lowers the possibility of sensitization and eventual corrosion.

What grade is 310S stainless flat steel?

Heat resistance: Under slightly cyclic conditions, 310S stainless steel has exceptional heat resistance, enabling it to tolerate temperatures as high as 10 °F (1100 °C).

Oxidation resistance: 310S stainless steel has exceptional oxidation resistance due to its high chromium and nickel content, which helps it withstand scaling and keep its structural integrity at high temperatures.

Good corrosion resistance is provided by 310S stainless steel, especially in mildly corrosive settings. It can be utilized in atmospheres that are somewhat carburizing and is resistant to sulfidation.

Strength and ductility: 310S stainless steel is easy to fabricate and weld because to its excellent ductility and strong strength at high temperatures.

variation with less carbon: Grade 310 stainless steel has a low carbon variation called 310S. Due to its low carbon content, shutdowns involving high-temperature gases or condensates are less likely to cause sensitization and subsequent corrosion.

Physical characteristics: Between 32 and 212°F, the specific heat of 310S stainless steel is 0.12 BTU/lb. Its density is roughly 8,000 kg/m2. After being annealed and cold-worked, it loses its magnetic properties.

Mechanical characteristics: 310S stainless steel has a minimum yield strength of 30 ksi, a minimum tensile strength of 75 ksi, and a 40% elongation. On the Brinell hardness scale, it is 217, and on the Rockwell B scale, it is 95.

What is the difference between a 310 and a 310S?

Carbon content: The maximum carbon percentage for 310 stainless steel is 0.08%, whereas 310S stainless steel has no maximum carbon content specified. 310S has a decreased carbon content, which improves its corrosion resistance and weldability.

Weldability: 310S stainless steel is more weldable than 310 stainless steel because of its reduced carbon content. This facilitates fabrication and handling in applications involving welding.

Corrosion resistance: 310S stainless steel is more corrosion resistant than 310 stainless steel because of its reduced carbon content. Because it is less likely to break down at high temperatures, it is frequently chosen for applications in hot conditions.

Resistance to heat cycling: Due to its superior resistance to thermal cycling, 310S stainless steel is typically chosen over 310 stainless steel. Because of its low carbon content, it is less likely to become sensitized and embrittled in hot conditions.

Applications: High-temperature settings are appropriate for the use of stainless steel types 310 and 310S. However, because of its superior resistance to thermal cycling, 310S stainless steel is frequently utilized in applications including furnace parts, kiln linings, and heat treatment facilities.

Applications of 310S Stainless Flat Steel

- Heat treatment equipment: Because of its exceptional high-temperature qualities, such as superior ductility, weldability, and corrosion resistance, 310S stainless steel is frequently used in high-temperature applications, such as heat treatment equipment.

- Chemical processing equipment: Because 310S stainless steel is resistant to oxidation, corrosion, and high temperatures, it is a good choice for use in chemical processing equipment. It is frequently utilized in the building of annealing covers, retorts, burners, and combustion chambers, among other things.

- Furnace parts: Radiant tubes, tube hangers, and thermowell are among the parts made of grade 310S stainless steel. It is appropriate for these applications due to its strong performance at high temperatures, resistance to oxidation, and outstanding creep resistance.

- Fluidized bed combustors: These are employed in a variety of industries for energy generation and combustion processes. 310S stainless steel is used in these combustors.

- Internal components of coal gasifiers: 310S stainless steel is a good choice for internal components of coal gasifiers because of its superior oxidation resistance and high-temperature strength.

- Food processing equipment: Lead pots, annealing covers, and cryogenic constructions are just a few of the uses for 310S stainless steel in the food processing sector. It is appropriate for these applications due to its resistance to corrosion and capacity to tolerate high temperatures.

- Components for cryogenic applications: Because of its low magnetic permeability and resilience at low temperatures, 310S stainless steel is frequently utilized in cryogenic applications.

- High-temperature environments: 310S stainless steel is widely used in all high-temperature settings where it is necessary to have good creep resistance, high-temperature strength, and resistance to scaling and corrosion.