Product Characteristics

Excellent corrosion resistance: It contains molybdenum and nickel elements that can retain stability in both acidic and alkaline environments and are resistant to common corrosive media like sulfuric acid, hydrochloric acid, chloride, etc.

Excellent high-temperature strength: It performs well at low temperatures and has good strength, plasticity, toughness, and cold formability.

Good mechanics: Able to endure high pressure and shock loads; good strength, hardness, ductility, and toughness.

It is resistant to friction and wear because of its abrasion resistance.

Solderability: 316L stainless steel seamless pipe can be welded in a variety of ways and has good welding performance.

Product Specification

| Outside diameter(OD)

|

1/8 inch (3.175 mm) -36 inches (914.4 mm) |

| Wall thickness(WT) | 0. 5 mm-40 mm |

| Length Range(LR) | Fixed lengths (e.g. 6m, 12m) or custom lengths as required |

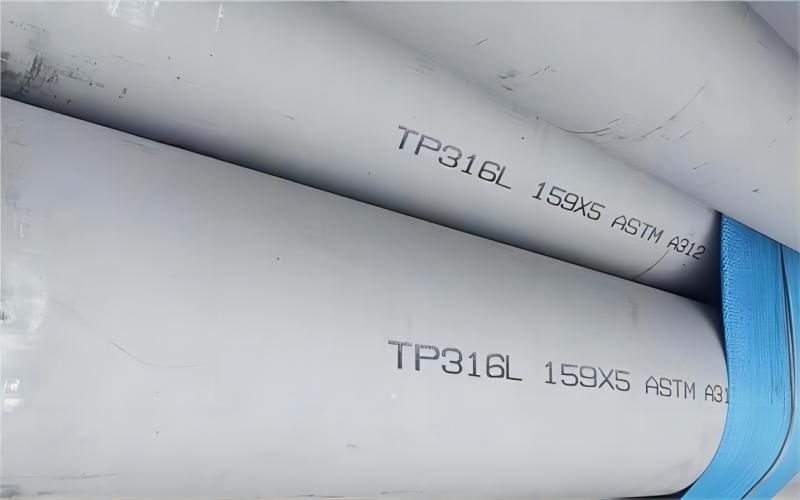

| Standard | ASTM, JIS, DIN, etc. |

What is the difference between 316 and 316L pipes, by the way?

First of all, the chemical makeup is different; 316L has superior corrosion resistance and lower carbon content. Second, 316L steel pipe has a stronger heat resistance and a superior anti-carbide precipitation function than 316 stainless steel pipe. The welded piece of 316 tubing needs to be post-welded to ensure the best corrosion resistance. The use of 316L stainless steel pipe eliminates the need for post-welding.

What is the advantage of 316L?

The raw materials can be applied safely in a variety of fields and are non-toxic. Since welded steel pipes have weak points at the interface that might leak or cause damage, seamless steel pipes are more trustworthy and durable since they have no weak points. They are also smaller than welded steel pipes.

Environmentally friendly , long-lasting and corrosion-resistant: These materials are ideal for creating environmental equipment like irrigation systems or sewage systems.

High economic efficiency: The market price is reasonable since the cost of the raw materials is reasonable.

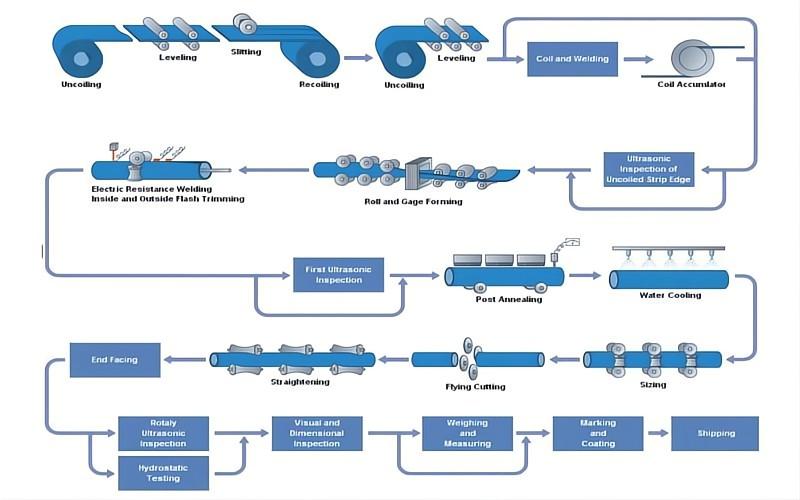

Manufacturing Process

Round bar preparation, heating, hot rolled perforation, head cutting, acid pickling, regrinding, degreasing, cold rolling processing, solution heat treatment, straightening, tube cutting, acid pickling, and finished product inspection are the steps involved in making 316L stainless steel seamless pipe.

Quality Control

316L stainless steel strip has been selling well as a common variant. However, there are many different types of stainless steel strips available, and the quality is inconsistent.

The production of raw materials must first be properly regulated in order to verify that they meet all applicable norms and requirements. Secondly, as correct control of manufacturing process parameters is necessary to ensure product quality, each processing step in the production process should be strictly regulated. Thirdly, rigorous testing and approval of final items to confirm compliance with pertinent standards and requirements. Traceability and high-quality documentation are also crucial.

To maintain both employee and environmental safety during the production process, producers must closely adhere to the applicable environmental protection and safety management regulations.

When a consumer is making a purchase, they should first inspect the product’s surface to see whether the thickness is proportional, whether it is smooth and level, and whether there are numerous pockmarks and rust traces. Although occasionally having a small pockmark on a 316L stainless steel belt is natural, try to choose the one with fewer when shopping. Additionally, customers should pay close attention to the product’s surface and select stainless steel manufacturers with a strong reputation.

Market and Competitive Conditions

Many manufacturers prefer 316L stainless steel pipe as it stands out among other stainless steel materials. And one of the key elements that customers take into account before making a purchase is price. Therefore, firms must learn to manage costs and enhance production effectiveness. So quality plays a big role in consumer decision-making. Producing high-quality goods requires manufacturers to follow tight quality control procedures, adhere to international standards, and meet certification requirements. Additionally, certain stainless steel pipe producers have developed strong brand recognition with a sizable customer base and sales network, which heightens competition in the market. To increase the performance and quality of their products, manufacturers must constantly innovate, create and use new materials, and enhance production techniques, so as to meet market demand.

Apply Recommendations

Food and beverage industry: It is frequently used to transport high-purity water, beverages, foods, and dairy products because of its non-toxic, hygienic, and corrosion-resistant properties.

Ornamentation: Making handrails, guardrails, doors, windows, stairs, and other architectural elements with superior surface polish and weather resistance.

Oil and gas industry: 316L stainless steel pipe can be utilized for equipment in oil refineries, storage tanks, and transmission lines for oil and gas.

Medical industry: It can be used to make medical devices like artificial joints, syringes, etc. because of its superior corrosion resistance and biocompatibility.

It may also be used to make aircraft, gas pipelines, and other structures thanks to its superior oxidation resistance and high-temperature resistance.

Gnee Steel Group is a supply chain enterprise integrating the design and processing of panels, pipes, profiles, outdoor landscaping, and the sales of international small products. It was established in 2008 with a vision to be the most competitive supply chain group in the global; ever since then, we have always been dedicated to fulfilling that vision with excellent, consistent, and innovative services. After several years of hard work, Gnee Steel Group has become the most professional steel supply chain international enterprise in the Central Plains.