What is 316 Stainless Flat Steel?

A form of stainless steel flat bar composed of grade 316 stainless steel is referred to as 316 stainless flat steel.

Compared to 304 stainless steel, 316 stainless steel is an austenitic chromium-nickel alloy with a greater nickel and molybdenum content. Its composition makes it more resistant to corrosion, particularly in chloride-containing settings. Additionally, it possesses higher tensile and stress-rupture strengths, improved resistance to pitting and crevice corrosion, and good resistance to creep.

Availability: Standard sizes of 316 stainless steel flat bars as well as bespoke cuts to desired lengths are both available. Metal superstores and suppliers offer it for purchase online.

Grade Comparison: 304 and 316 stainless steel are frequently contrasted. While 316 stainless steel has stronger corrosion resistance, particularly in situations with chlorides, both grades are austenitic and have excellent corrosion resistance. In comparison to 304 stainless steel, it is also marginally stronger, less pliable, and less machineable.

The Distinctions Between Angle, Channel, and Flat Stainless Steel

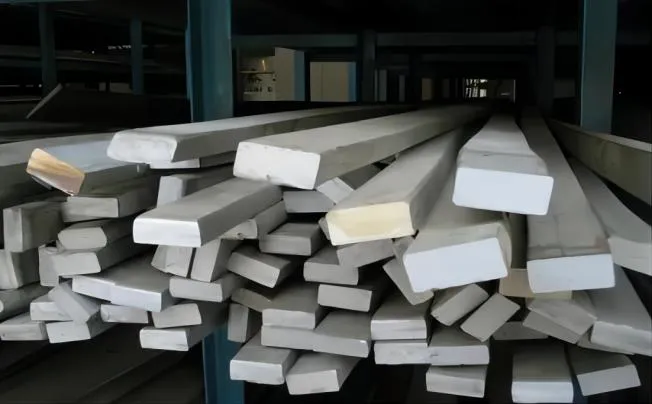

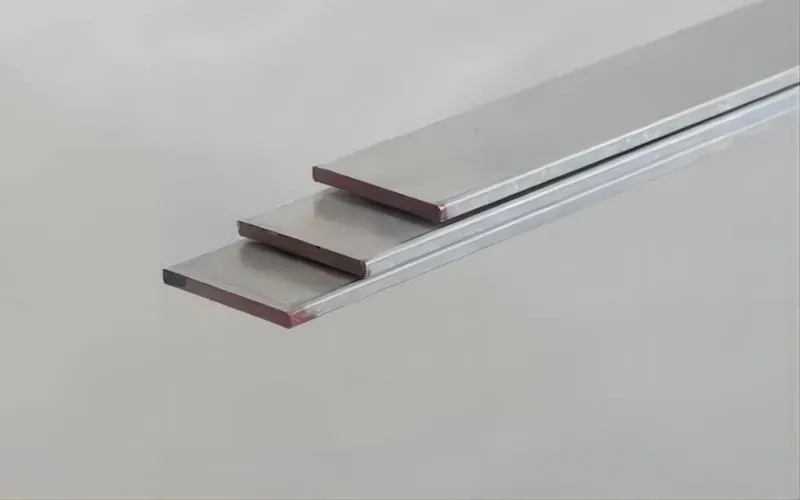

Stainless Steel Flat Steel

Stainless steel flat steel is a versatile steel product with a rectangular shape that is frequently utilized in a variety of industrial and construction applications. True Bar and Sheared and Edge Bar are the two variations that are offered. Sheared and edge bars are cut from a stainless steel coil, and true bars are rolled to the required thickness.

True Bar is appropriate for applications requiring great accuracy because of its precise dimensions and tolerances. However, because of the cutting process, Sheared and Edge Bar may have significantly less exact measurements.

Stainless steel flat steel is very strong, resistant to corrosion, and workable on-site. It is frequently employed in outdoor or maritime applications, machinery, and buildings.

Angle Steel

Angle steel is a section of structural iron or steel with a 90-degree angle. It is also referred to as structural angle or L-shaped cross-section steel.

It is frequently utilized in ordinary fabrication, repairs, and structural applications. Angle steel can have legs that are uneven in size or equal in size, also known as flanges.

Angle steel specifications are usually stated in terms of the legs’ width and thickness.

Angle steel can be utilized in certain applications to give bracing, enhance gate integrity, and increase structural support.

Channel Steel

Channel steel is a lengthy steel with a cross-section that is shaped like a groove and resembles the letter “C.” Another name for it is C-section steel.

The segment of channel steel is shaped like a groove and has the same width for both the upper and lower legs.

Channel steel is frequently utilized in the construction of buildings, mechanical equipment, curtain walls, and automobiles.

It is adaptable and useful for supporting structure in a range of settings. While some varieties of channel steel may have extra features to promote rigidity, others may just have holes or perforations for bolting purposes.

Applications of 316 Stainless Flat Steel

- Chemical and Petrochemical Industry: Because 316 stainless steel is resistant to corrosive chemicals and high temperatures, it is frequently utilized in this industry. It is a component of machinery like pipes, pressure vessels, and storage tanks.

- Food Processing and Pharmaceutical Equipment: 316 stainless steel is appropriate for use in food processing and pharmaceutical equipment due to its resistance to corrosion. It is utilized in piping systems, storage tanks, and manufacturing equipment.

- Marine Applications: 316 stainless steel has exceptional resistance to corrosion in maritime settings, particularly in the presence of chlorides. It is utilized in offshore structures, boat fittings, and marine equipment.

- Medical Devices: 316 stainless steel is appropriate for use in surgical tools and implants due to its non-reactive and corrosion-resistant qualities.

- Architectural and Construction: Where corrosion resistance is necessary, 316 stainless steel is employed in architectural projects and construction applications. It is utilized in handrails, structural elements, and building facades.

- Heat Exchangers: Because 316 stainless steel resists corrosion and high temperatures, it is frequently used in heat exchangers.

- Automotive sector: Exhaust systems, decorative trimmings, and components exposed to corrosive conditions are just a few of the uses for 316 stainless steel in the automotive sector.

- Industrial Equipment: Pumps, valves, fittings, and machinery parts are just a few of the items in industrial equipment that employ it.

- Water Treatment: Desalination plants, wastewater treatment centres, and pipe systems are examples of water treatment applications that use 316 stainless steel.

- Architectural Hardware: Where corrosion resistance and aesthetic appeal are crucial, 316 stainless steel is utilized in architectural hardware, such as door handles, hinges, and fixtures.