Why does stainless steel 316 rust?

The surface of stainless steel 316 corrodes or gets damaged, which is the initial cause of rust. Second, iron still serves as the foundation of stainless steel 316, despite its strong resistance to corrosion. It has the following chemical makeup: The following percentages are given: silicon (Si): 0.75%, phosphorus (P): 0.045%, sulfur (S): 0.03%, carbon (C): 0.08%, iron (Fe): remaining, nickel (Ni): 10%–14%, molybdenum (Mo): 2%–3%, manganese (Mn): 2%. Its surface may therefore deteriorate in certain environmental circumstances, such as those that are wet, acidic, or contain corrosive materials.

We must be mindful of the following things to keep stainless steel 316 from rusting:

1. Keep it dry: Steer clear of damp environments when handling stainless steel 316. Rust may be efficiently avoided by keeping it dry.

2. Frequent cleaning: To maintain the luster and corrosion resistance of stainless steel 316, clean its surface on a regular basis using a moist cloth or neutral detergent to get rid of dirt and contaminants.

3. Prevent contact with corrosive materials: To stop surface corrosion, keep stainless steel 316 away from food, liquids, and other corrosive or acidic materials.

4. Select the appropriate surface treatment technique: The corrosion resistance of stainless steel 316 is significantly influenced by the surface treatment technique used. Selecting a surface that has undergone appropriate treatment—such as passivating stainless steel surfaces or applying anti-rust coatings—can increase its resistance to corrosion.

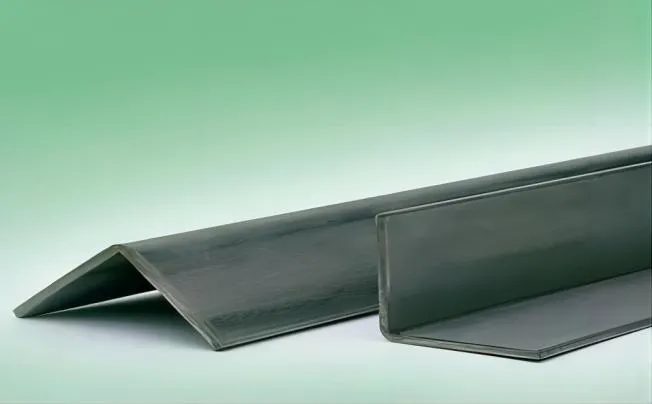

What is 316 stainless-angle steel?

Angle made of 316 stainless steel Steel is the term for an angle-shaped structural structure composed of grade 316 stainless steel. Among austenitic stainless steels, grade 316 is the second most sought-after grade after grade 304. It is an alloy of stainless steel. The price difference between 316 and 316L stainless steel is usually negligible.

When it comes to general corrosion resistance, grade 316 stainless steel outperforms grade 304, especially in settings with chloride.

Content of molybdenum: Grade 316 stainless steel is more resistant to corrosion when molybdenum is present, which makes it appropriate for applications where chemical attack—particularly from chloride solutions—is a possibility.

What is stainless-angle steel?

Angle stainless steel Steel is a structural profile composed of stainless steel, sometimes referred to as stainless steel angle steel. Its strength, resistance to corrosion, and adaptability make it useful in a wide range of applications. There are several grades of lower stainless steel angles available, including 304 and 316L. There are several sizes and profiles available to meet the needs of a given project. 316 stainless steel, also referred to as marine grade or food grade stainless steel, is well suited for use in marine environments and has corrosion resistance against a variety of chemical and acidic corrodents.

Applications of 316 stainless angle steel

- Industrial equipment: 316 stainless steel is frequently utilized in industrial equipment for a variety of purposes, such as pressure vessels, cisterns, and pipes for chemical applications, pharmaceutical manufacturing, chemical manufacturing, and industrial and chemical transportation.

- Medical equipment: Because 316 stainless steel is non-reactive, it is utilized in the production of surgical instruments for medical use.

- Marine equipment: 316 stainless angle steel can be utilized in marine equipment since it resists deterioration brought on by sea environments.

- Outdoor site furnishings: Because 316 stainless steel resists corrosion and is long-lasting, it is utilized in the manufacture of outdoor site furnishings.

- Commercial kitchens: Because of its hygienic qualities and resistance to corrosion, 316 stainless-angle steel is used in commercial kitchens.

- Food production and processing: The food industry uses 316 stainless steel for applications like food production and processing, especially in salty environments.

- Storage tanks: Because of its strength and resistance to corrosion, 316 stainless steel is used in the building of storage tanks.

- 316 stainless-angle steel is utilized in architectural applications where aesthetic appeal and resistance to corrosion are crucial considerations.

- Chemical processing: Because of its high thermal strength and resistance to corrosion, 316 stainless steel can be used in chemical processing applications.

- Pharmaceutical equipment: Because 316 stainless angle steel resists corrosion and has hygienic qualities, it is utilized in the production of pharmaceutical equipment.