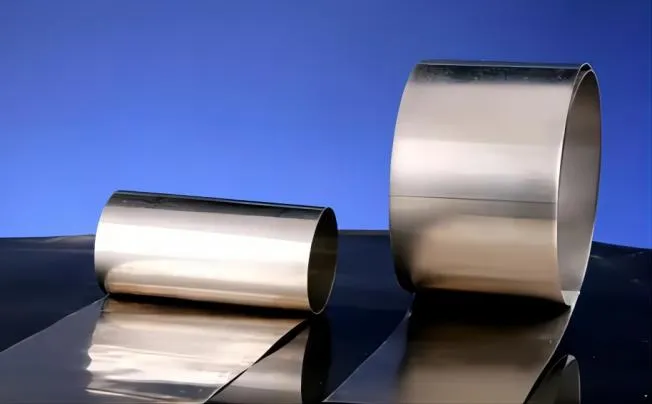

Product Specification and Characteristics

High-temperature resistance: 310S stainless steel foil maintains good heat resistance in high-temperature situations, with temperatures reaching 1100°C.

It has good corrosion resistance and can withstand oxidizing fumes and oxidation at high temperatures.

Antioxidant properties: it can fight sulphuric acid in flue gas, extending its service life.

310S stainless steel foil has excellent mechanical qualities, including high tensile strength and elongation.

| Item | 310S Stainless Steel Foil |

| Thickness | 0.01mm~3mm |

| Width | 100mm~2000mm |

| Length | 1000mm~6000mm |

The execution standards of 310S stainless steel foil can be chosen by the standards of various countries and regions. The following are the most prevalent execution standards:

National Standard of the People’s Republic of China (GB): for example, GB/T 24511-2017, “Stainless steel and alloy plates, strips, and foils.”.

ASTM A240/A240M-20 is “Heat Resistant, Corrosion Resistant, and Cold Working Stainless Steel,” for example.

EN 10088-2, “Stainless steel: Part 2: Technical delivery conditions for steel,” is one example of a European Standard (EN).

ISO 9445-2 “Surface quality of continuous cold-rolled stainless steel sheets, strips, and foils” is an example of an international standard. In addition, additional national or regional standards, such as the Japanese JIS standard, the British BS standard, and so on, can be applied to 310S stainless steel foil. The specific executive standard used is determined by where the product is used, market requirements, and client needs. When acquiring 310S Stainless Steel Foil, it is recommended that the execution standard be clarified with the supplier to guarantee that the product’s quality and performance fulfil the requirements.

What is the difference between a 310 and a 310S?

The austenitic chromium-nickel stainless steel pipe 310S contains a high proportion of nickel (Ni) and chromium (Cr). It possesses good high-temperature resistance, as well as oxidation and corrosion resistance. Finally, because of its increased high-temperature performance and corrosion resistance, 310S stainless steel is commonly used in high-temperature furnace pipes, heat treatment machinery, furnace chambers, and other industrial applications.

What is the difference between 310S and 316SS?

1. Both 310S and 316 have a carbon content of approximately 0.08% and contain nickel, chromium, a trace of sulfur, phosphorus, silicon, and other components in varying proportions. Because it contains more chromium, the former is more resistant to high-temperature oxidation, corrosion, and vulcanization.

2.310S is suitable for environments with strong acids, alkalis, and other corrosive media, whereas 316 has excellent corrosion resistance in corrosive environments due to the presence of molybdenum, particularly resistance to chloride ions, and is suitable for chlorine-containing media such as seawater.

3. The former is often used in high-temperature situations and is ideal for high-temperature welding, whereas the latter is prone to intergranular corrosion in high-temperature settings and is acceptable for standard welding circumstances.

Applications of 310S Stainless Steel Foil

Heat treatment equipment: Because of 310S stainless steel foil’s excellent temperature resistance, it is often used to manufacture heat insulation barriers and sheets for high-temperature equipment such as heat treatment furnaces, melting furnaces, and annealing furnaces.

Chemical equipment: because of its high corrosion resistance, it is frequently used to manufacture chemical equipment such as flue gas purifiers and petrochemical equipment.

Power generating equipment: Because of its high-temperature resistance, it is frequently used to manufacture power generation equipment such as gas turbines, boilers, boiler exhaust pipes, and so on.

Environmental protection facilities: Because 310S stainless steel foil environmental health does not emit pollutants and can withstand corrosion and oxidation in high temperatures, it is frequently used in the production of environmental protection facilities such as sewage treatment equipment, waste gas treatment devices, and waste incinerators.

In general, 310S stainless steel foil is widely used in heat treatment, chemical industry, power generation, environmental protection, and other areas of equipment manufacturing due to its excellent heat resistance and corrosion resistance in high temperature environments and corrosive media.

Product Market Competition and Demand

- Market competition: Brand competition: There are various well-known brands in the market that manufacture 310S stainless steel foil, and these companies compete for market share in terms of quality, technology, and service.

- Technological competition: different manufacturers may utilize different production procedures and equipment, all with the goal of enhancing the quality and performance of 310S stainless steel foil and seeking to differentiate their goods for a competitive edge.

- pricing competition: As market rivalry has increased, pricing has been an essential factor in consumer purchase decisions. To attract clients, producers may compete in the market by lowering the price of their items.

- Market Demand: Stainless steel foil is used in a variety of industries, including mechanical, electronic, medical, food processing, and others. Quality is highly sought after, particularly in the food, pharmaceutical, and electrical industries. Second, as people’s need for high-quality life and décor grows, so does the demand for architectural ornamentation. In contrast, as new technologies and applications arise, the stainless steel foil market is witnessing new demand prospects. Electric car adoption, for example, has raised demand for lightweight, corrosion-resistant stainless steel foils. Furthermore, the growth of the renewable energy industry creates new market prospects for it.