What is the difference between 310 and 310S stainless steel?

1. 310 has a maximum carbon concentration of 0.25% and contains 25% nickel, 20% chromium, and trace amounts of sulfur, phosphorus, silicon, and other elements. Despite being a low-carbon version of 310 stainless steel, 310S includes up to 0.08% carbon.

2. They are all resistant to high-temperature oxidation and can maintain strength in hot settings.

3. Both display moderate to good corrosion resistance in various situations and temperatures.

4. 310S is easier to weld and less prone to sensitization and embrittlement at high temperatures because it contains less carbon. Because of its high carbon content, 310 is prone to intergranular corrosion problems during welding, making it vital to regulate the welding conditions during high-temperature welding.

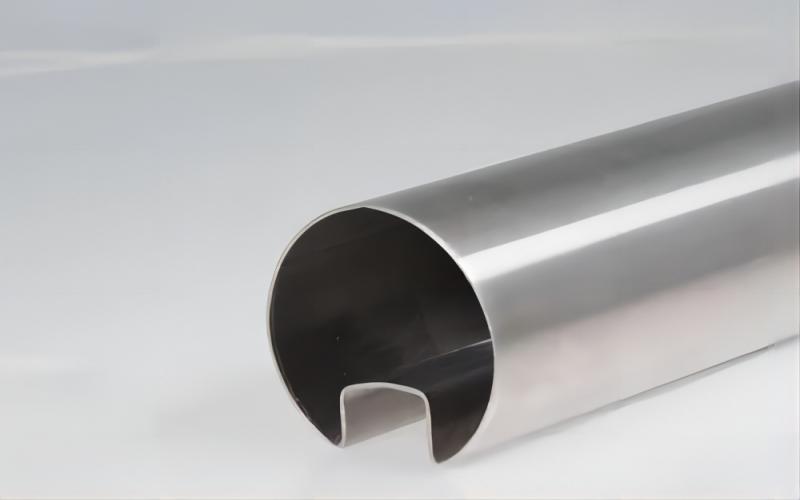

Product Specification, Characteristics, and Applications

| Item | 310 Stainless Steel Groove Tube | |

| Standard | ASTM, DIN, JIS, or customized size required by customers | |

| Material | C, Fe, Mo, Mn, Si, N, etc. | |

| Size | Wall Thickness | 0.3mm~5mm |

| Outer Diameter | 6mm~100mm | |

| Inner Diameter | 3mm ~ 80mm | |

1. Corrosion resistance: 310 stainless steel groove tube has excellent corrosion resistance, including resistance to oxidation, nitriding, and sulfidation, which is important for high-temperature, harsh-environment, or chemical-exposure applications. The grooves on the tube may serve to increase the uniformity, stability, and consistency of the surface’s protective oxide layer, lowering the likelihood of localized corrosion or stress corrosion cracking. Furnaces, petrochemical equipment, conduits, masts, anchor chains, distillation columns, storage tanks, and so on are examples.

2. High-temperature resistance: It possesses exceptional high-temperature qualities, including as strong creep strength, thermal expansion, and thermal conductivity, making it appropriate for applications requiring heat, steam, or thermal cycling resistance. The grooves on the tube may aid in heat dissipation and the prevention of localized overheating or distortion. Furnaces, electrical instruments, hardware accessories, and so forth are examples.

3. Low magnetism: It is non-magnetic stainless steel with low magnetic characteristics. As a result, it is better suited for particular applications such as electronic equipment production and precision instruments, such as aircraft and automotive parts.

4. It has good processing performance and can sustain plasticity and malleability in both cold and hot working procedures.

What is the difference between 310 and 304 stainless steel?

310 stainless steel has greater chromium (24-26%) and nickel (19-22%) content than 304 stainless steel (18% chromium and 8% nickel). Another 310 stainless steel has a trace of manganese (up to 2%).

Mechanical properties: The former is often harder than the latter, has less ductility, but more strength and toughness, and is ideal for high-temperature and high-pressure working situations.

High-temperature resistance: 310 stainless steel is high-alloy stainless steel with good high-temperature resistance, making it suited for use in hot environments. Because 304 stainless steel has a low tolerance for high temperatures, its maximum use temperature is usually limited to less than 800 degrees Celsius.

Melting point and freezing point: The latter has a melting temperature range of about 0-1450 °C, whereas the former has a melting temperature range of about 1050-1150 °C.

Uses: 310 stainless steel is appropriate for high temperature, high pressure, and corrosive conditions, whereas 304 stainless steel is appropriate for common application scenarios.

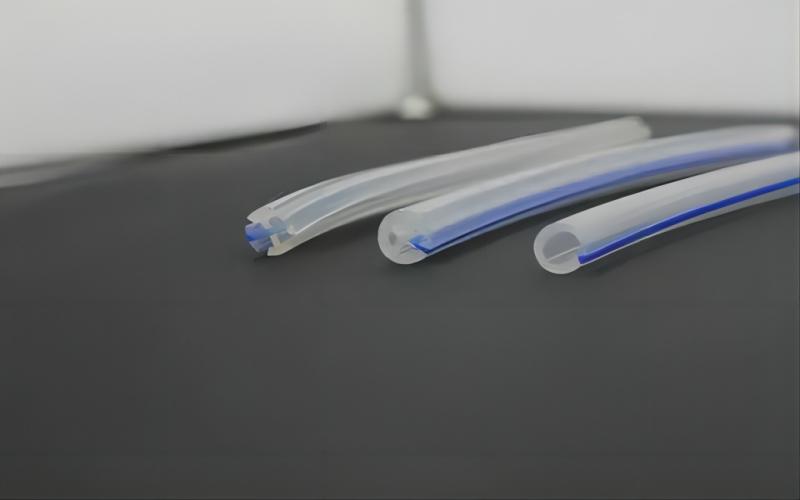

What is the difference between a fluted tube and Stainless steel grooved tube?

A fluted tube is a piping system used in water supply, fire, and air conditioning systems that has the cross-sectional shape of a trench or groove and is typically constructed of metal (steel, stainless steel) or plastic (PVC). It can be used to improve flow patterns, create ornamental designs, and improve heat transmission, among other things. Grooved tubes can be built from a variety of materials, including stainless steel, but are not restricted to stainless steel and can have a variety of geometries and sizes.

The cross-sectional geometry of stainless steel grooved pipe is grooved, with grooves typically distributed along the pipe’s length. It is normally built of a specific stainless steel grade, such as 304 or 316L, and can have varying wall thicknesses, diameters, and trench patterns.

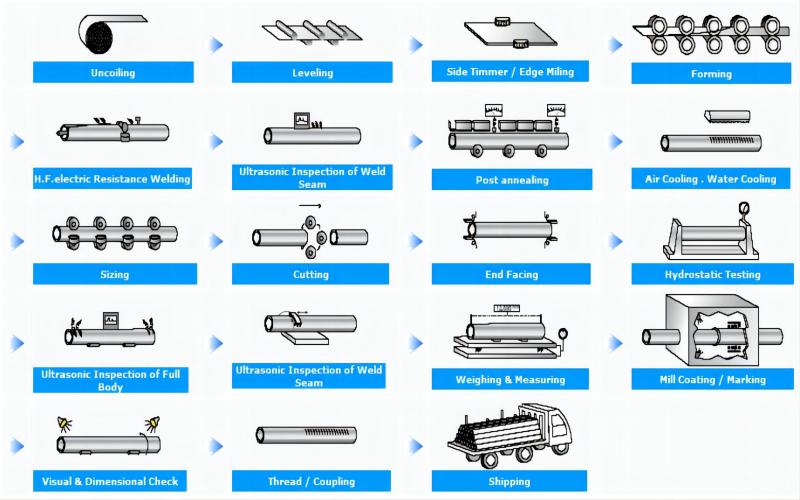

Manufacturing Process for 310 Stainless Steel Groove Tubes

310 stainless steel groove tubes are created by passing a stainless steel sheet through two rollers with grooves around their circumference, resulting in a groove or channel in the sheet. The sheet can then be molded and welded into a tube or pipe.

The groove or channel in the sheet can be formed using a variety of methods, including cold rolling, hot rolling, and extrusion, depending on the required application and product requirements. The groove or channel in the sheet might be a single groove or a series of grooves, depending on the intended application of the finished product.

The shape and size of the finished tube or pipe might vary substantially depending on the precise application and product requirements.

Market Competition and Prospect

Rising demand from industries such as construction, automotive, and chemical processing, as well as the development of new stainless steel grades and applications, are likely to propel the global stainless steel market forward. The stainless steel market is highly competitive since various global and regional rivals offer a comprehensive range of products and services, including flat items, long products, pipes, and tubes, as well as manufacturing, engineering, and distribution services. In addition, the stainless steel industry faces challenges such as fluctuating raw material prices, rising competition from low-cost producers in emerging regions, and the need to adapt to changing customer needs and environmental rules. In terms of the stainless steel sector’s forecast, rising regions such as Asia Pacific and Latin America, as well as novel stainless steel uses in industries such as medical devices, renewable energy, and 3D printing, show promise.

The Gnee Steel Group is a supply chain firm that combines panel design and processing, pipes and profiles, outdoor landscaping, and overseas small product sales. It was founded in 2008 to be the most competitive supply chain group in the world; since then, we have been committed to achieving that goal with great, consistent, and creative services. The Gnee Steel Group has become the most professional steel supply chain worldwide firm in the Central Plains after many years of hard labor.