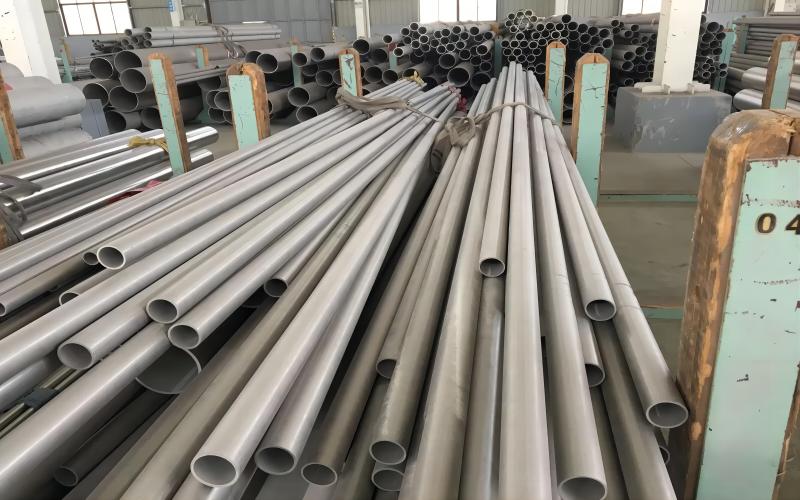

Product Characteristics

Good corrosion resistance: 309 stainless steel seamless pipe can withstand media erosion from acids, alkalis, and other substances.

Excellent high-temperature performance: In high-temperature situations, it maintains exceptional strength and corrosion resistance.

Excellent mechanical qualities: It can endure high pressure and heavy loads and has good tensile strength, bending resistance, and impact toughness.

Austenitic structure with good thermal conductivity and thermal expansion, stable organizational structure.

Better processability: Cold working or hot working can be used to execute processes including forming, welding, and machining.

Product Specification

| Item | 309 Stainless Steel Seamless Pipe

|

| Outside Diameter(OD)

|

1/8 inch (3.175 mm) -36 inches (914.4 mm) |

| Wall Thickness(WT) | 0.049 inch – 2 inches (1.244 mm to 50.8 mm). |

| Length Range(LR) | Fixed lengths (6m) or custom lengths as required. |

| Standard | ASTM, EN, GB, etc. |

What is the difference between 309 and 309S?

Austenitic chromium-nickel stainless steel 309S is a seamless stainless steel. It is a derivative steel made from 309 with less carbon than that steel. Compared to 304 stainless seamless steel, 309S stainless steel is more resistant to heat and corrosion, can sustain repeated heating below 980°C, and has greater high-temperature strength, oxidation resistance, and carburization resistance. The nickel concentration is low while the chromium content is high. It is a high nickel austenitic stainless steel, which is used to make steel that is more heat resistant. Unlike 309S, seamless 309 stainless steel pipe does not include sulfur S content. Although it has more corrosion resistance than alloy 310, it has a higher oxidation resistance. The steel factories consequently manufacture more 309S stainless steel.

Advantages of 309 stainless steel seamless pipe

Strong and long-lasting: Steel pipes made of 309 stainless steel seamless are (in comparison) steel pipes that are corrosion-, impact-, abrasion-, and impact-resistant, as well as having a long service life. They can thus satisfy a range of needs.

Saving on pipes: Snap connections don’t need threads, therefore thin-walled pipes can be used. The pipe’s inner diameter is expanded at the same time for the same nominal diameter, allowing the pipe’s diameter to be reduced for the same flow conditions thus conserving the pipe.

Convenient design: At the moment, the fastest and most labor-efficient connecting method is the snap connection. A link may be made in 10 seconds, which can cut the construction period in half. No welding or threading, a neat and orderly building site, and no constant fire.

High quality and affordable: As technology has matured and developed, thin-walled stainless steel pipes have grown more common, and their cost has also significantly decreased.

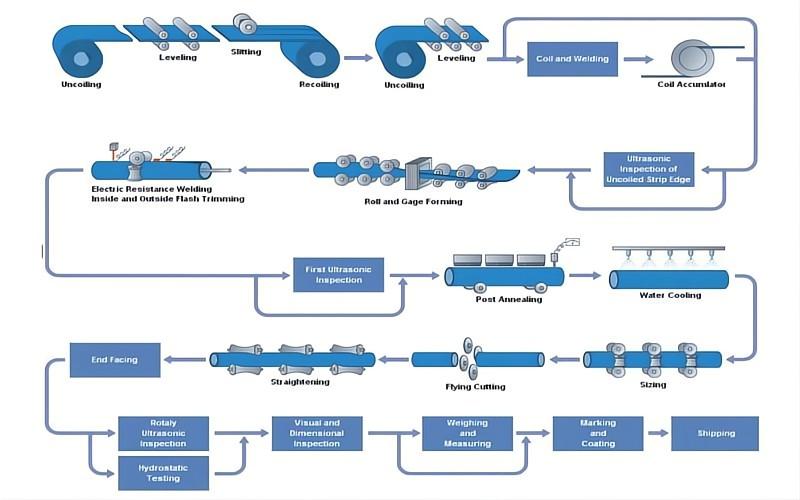

Manufacturing Process

1. The first step in the production of seamless pipes made of 310 stainless steel is to choose high-quality materials.

2. A furnace is used to melt the chosen raw materials. The composition is adjusted in the molten metal to achieve it. When the metal is ready to be formed into billets or ingots, it is poured into molds.

3. To make the billets or ingots pliable for further processing, they are heated to a specified temperature. This process, known as billet heating, ensures that the material is prepared for the next process.

4. To form a hollow center, a sharp instrument is used to pierce the heated billet. This process gives the pipe its basic shape. The punctured billet is then lengthened and shortened to its diameter.

5. The pipe goes through heat-treatment procedures like annealing or normalizing after rolling.

6. Various finishing procedures are performed on the pipe once the heat treatment is finished. To acquire the required shape and final dimensions, these can involve techniques including straightening, cutting, sizing, and beveling.

7. To make sure the pipe complies with the requirements and regulations, quality inspections are carried out at every stage of the production process.

8. After passing all quality inspections, the pipe is given one last examination. The pipe is packaged to ensure its safety during shipment after being checked to make sure it complies with the necessary standards.

Quality Control

The manufacturing of raw materials, including their chemical composition, physical characteristics, material certification, etc., must first be properly regulated to guarantee that they meet all applicable norms and requirements. In order to guarantee the products’ dimensional accuracy, functionality, and surface quality, the production process—including heating, rolling, piercing, cold drawing, and annealing—should be managed and monitored. Thirdly, to make sure that the product complies with the required size range and composition criteria and is free of evident flaws and surface damage, dimensions and visual examination as well as chemical composition analysis are crucial. To prevent product damage, deformation, or contamination as well as to ensure that they are kept in good condition during transit and storage, regulate and supervise the delivery and packaging process.

Market and Competitive Conditions

The growth of China’s stainless steel industry is heavily reliant on exports, which account for a sizable portion of the country’s overall industrial development. On the one hand, China’s stainless steel industry defends its rights in the challenging export of other nations, but the most crucial issue is that China’s stainless steel industry should continue to raise its quality level and carry out thorough upgrading.

We can only succeed in achieving an unbeatable position in international trade by continuing to improve product quality, better developing overseas trade, managing the suppression of trade protectionism, combining products with environmental protection, energy resources, and the human environment, and increasing the competitiveness of stainless steel products in the face of the economic downturn and slowing development speed.

What is 309 steel pipe used for?

Decorative field: Making handrails, guardrails, doors, windows, stairs, and other structures with a nice surface quality and weather resistance.

Food and beverage industry: It is frequently used to transport high-purity water, drinks, foods, and dairy products because of its attributes of being non-toxic, hygienic, and corrosion resistant as well as its low water leakage rate and superior water permeability. For instance, it makes a good delivery conduit for drinking water.

Industrial industry: it is primarily employed in mechanical instruments, industrial conveying pipelines, and other mechanical structural elements. It is also utilized in the petroleum, chemical, medical, food, light industry, and other industries. for instance, gas pipes, storage tanks, etc.

Gnee Steel Group is a supply chain enterprise integrating the design and processing of panels, pipes, profiles, outdoor landscaping, and the sales of international small products. It was established in 2008 with a vision to be the most competitive supply chain group in the global; ever since then, we have always been dedicated to fulfilling that vision with excellent, consistent, and innovative services. After several years of hard work, Gnee Steel Group has become the most professional steel supply chain international enterprise in the Central Plains.