Product Specification and Characteristics

1. Good corrosion resistance: Because it contains 8% nickel and 18% chromium, it is resistant to corrosion and can be used in environments with strong acids, strong alkalis, and other corrosive media.

2. High strength and hardness: After cold rolling or cold drawing processing, the material has high strength and hardness, allowing it to endure more weight and pressure in some circumstances.

3. Solderability: This property makes a material simple to handle, weld, and connect to other stainless steel pipes.

4. It’s beautiful: Thanks to its distinctive shape and metal texture, it offers wonderful, contemporary, and long-lasting design qualities. The surface is bright and flat, appropriate for indoor and outdoor architectural decorating, furniture construction, etc.

5. Safe and hygienic: non-toxic, odorless, won’t contaminate liquid being transported, and complies with health standards.

| Item | 304 Stainless Steel Square Tube

|

|

| Type | hot rolled and cold rolled | |

| Size | Wall Thickness | 0.5~6mm |

| Outer Diameter | 3mm~300mm | |

What is the difference between 304 and 316?

Chemical composition: 316 contains molybdenum, whereas 304 does not.

Corrosion resistance: Because 304 has less nickel than 316, it is less resistant to corrosion.

Performance: 316 has improved corrosion and heat resistance due to the addition of molybdenum.

Application range: While 304 is frequently used in the production of pots and pans, 316 is frequently utilized in the food, medical, watch, and other industries.

Price: Because 316 is food grade, it has superior corrosion resistance, hence it will cost more than 304.

Applications of 304 Stainless Steel Square Tube

1. Building decoration: The material is a popular choice for both indoor and outdoor architectural decoration because of its brilliant, smooth surface and outstanding corrosion resistance. for instance, wall decorations, chairs, guardrails, and doorknobs.

2. Food and medical fields: as it is non-toxic, odorless, and won’t cause pollution, it is widely used in the food processing sector and the medical profession. It also complies with health standards and requirements for global sustainable development. such as coffee cups, surgical instruments, medicinal supplies, etc.

3. Kitchen and bathroom fixtures: odorless, non-toxic, and strong corrosion resistance. It is also simple to clean and does not readily conceal filth, making it suitable for use in bathroom pipes, kitchen sink pipes, range hood pipes, and other fixtures.

4. Chemical and petroleum industry: Because of its superior bending strength and resistance to high pressures and high temperatures, it can be used to transport a variety of chemical media and petroleum products, including storage tanks and pipeline transportation.

5. Transportation: It is a dependable material choice for the automotive and aerospace industries, utilized to build exhaust pipes, body structure components, and more due to its high strength, corrosion resistance, and high-temperature resistance.

6. Other industries: 304 stainless steel square tubes can also be used to make piping systems and parts for the electronics, metallurgy, and energy sectors.

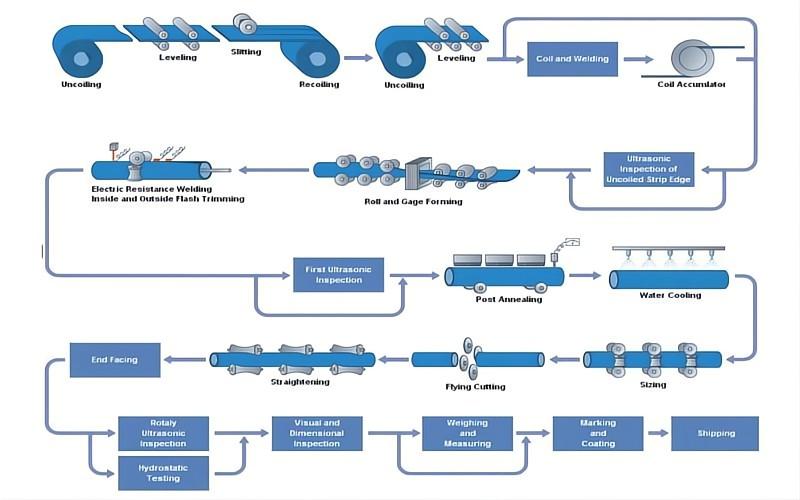

Manufacturing Process

Unwinding, cleaning equipment, feeding instructions, forming, welding, internal leveling of welds, external weld grinding, shape and sizing, solid melting treatment, final sizing, straightening, flaw identification, spray coding, sizing, cutting (coiling), splicing, etc.

Quality Control

The production of raw materials must first be properly regulated in order to verify that they meet all applicable norms and requirements. Secondly, as correct control of manufacturing process parameters is necessary to ensure product quality, each processing step in the production process should be strictly regulated. Thirdly, rigorous testing and approval of final items to confirm compliance with pertinent standards and requirements. Traceability and high-quality documentation are also crucial.

To maintain both employee and environmental safety during the production process, we will closely adhere to the applicable environmental protection and safety management regulations.

The Difference Between 304 Tubes and 304 Seamless Pipes

First, 304 stainless steel square pipe is often made by the welding process, which entails bending stainless steel plate into a square shape. By heating and drawing the stainless steel blank, the 304 stainless steel seamless pipe uses a seamless processing technique to create a seamless pipe. Second, 304 stainless steel square pipe has a square or rectangular cross-sectional shape with four right angles. 304 stainless steel seamless pipe has a circular, non-right-angled cross-sectional shape. Thirdly, 304 stainless steel seamless pipe has more strength and pressure resistance than square pipe because of the various manufacturing procedures. Because the seamless pipe is manufactured without welds and has a more consistent structure, it has greater strength and pressure resistance. Finally, due to the relatively straightforward welding procedure, the cost of producing 304 stainless steel square pipe is minimal. Because the manufacturing of 304 stainless steel seamless pipe is more complex and requires more sophisticated machinery and technology, the cost of production is greater. As a result, users should select the proper pipe type based on the particular user requirements and application scenarios.

Market Competition and Prospect

In recent years, productivity has continued to increase. Materials made of stainless steel have been employed fast and extensively in a variety of industrial applications. China’s demand and consumption of stainless steel materials increased from 260,000 T in 1990 to around 5.6 million T in 2006, according to pertinent figures. rise of almost 22x from year to year. This pattern is getting stronger. Due to its affordable price—304 stainless steel square pipe costs less than half as much as 300 series stainless steel—the majority of users adore it, and demand for such products is rising.

The Gnee Steel Group is a supply chain business that combines the design and manufacture of panels, pipes, and profiles with outdoor landscaping and the sales of small goods internationally. Since its founding in 2008, we have been committed to realizing the company’s mission of becoming the most competitive supply chain group in the world by providing exceptional, reliable, and cutting-edge services. After putting up many years of effort, Gnee Steel Group has emerged as the Central Plains’ most skilled steel supply chain international firm.