304 Stainless Steel Corrugated Plate Definition

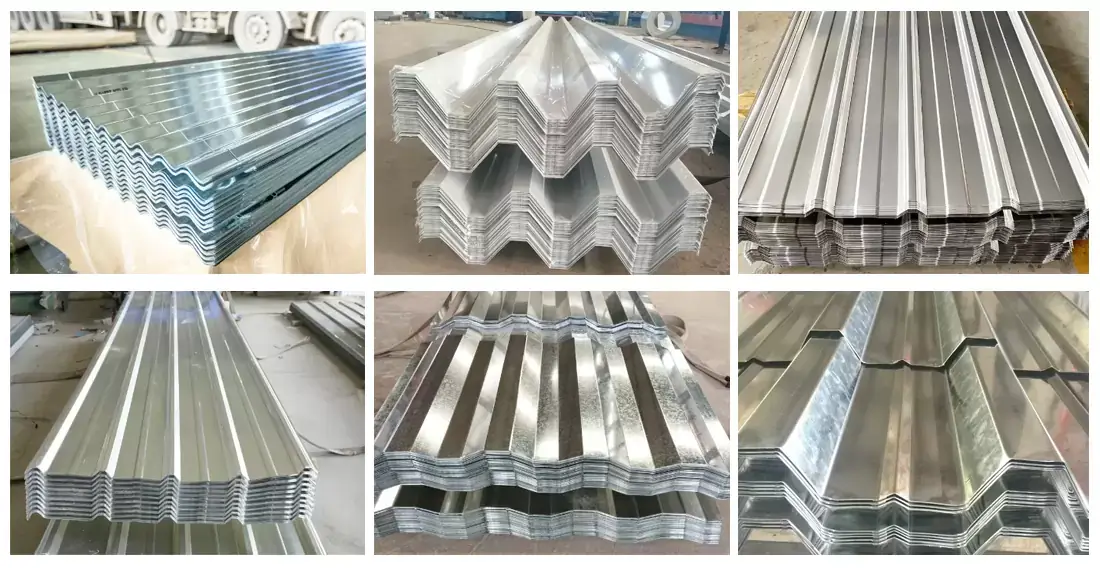

304 Stainless steel corrugated plate is generally made by 304 stainless steel plate with corrugated or wavy patterns. These patterns serve to enhance the plate’s strength and stiffness, rendering it suitable for applications wherein structural integrity is of the utmost importance. Furthermore, the corrugated design also offers a certain aesthetic appeal, making it a favored choice in architecture and decoration.

304 Stainless Steel Corrugated Plate Specification

| Material | stainless steel plate |

| Grade | 304 |

| Standard | JIS, AISI, ASTM, GB, DIN, EN |

| Thickness | 0.2 – 12 mm |

| Width | 600 – 1500 mm (support customization) |

| Length | 800 – 5000 mm (support customization) |

| Tolerance | ±1% |

| Finish | brushed, color coated, sandblasted, polished, etc |

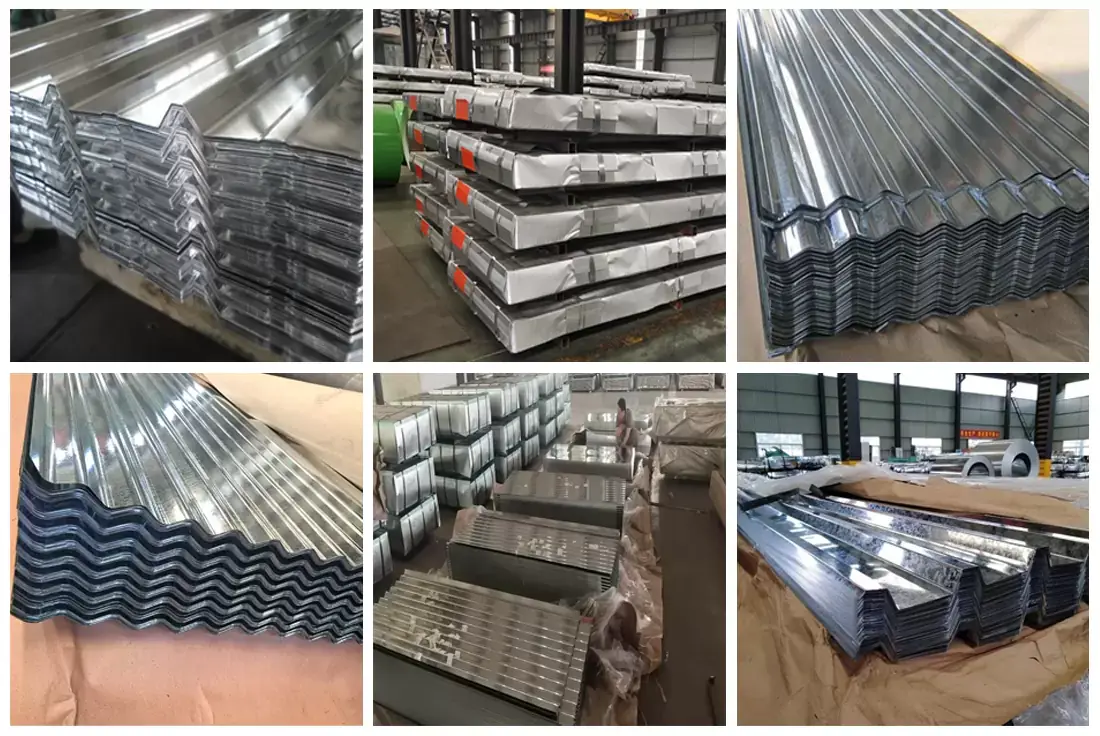

| Packing | PVC + waterproof or paper + wooden package |

304 Stainless Steel Corrugated Plate Properties

304 stainless steel corrugated plate possesses various properties that render it highly sought-after in diverse industries. They include:

1. Excellent Corrosion Resistance

Made of stainless steel material, it has extremely high corrosion resistance, which is not easy to rust and can maintain good surface quality and performance in humid and acid-base environments. Whether in marine environments or chemical equipment, 304 stainless steel corrugated sheets can be used for a long time without being affected by corrosion.

2. High Strength

It also has excellent strength, which can effectively prevent damage from external factors. The plate can effortlessly withstand heavy loads, impacts, and even the most extreme weather conditions. Its robust nature renders it suitable for applications necessitating structural stability and long-lasting performance, thus earning it widespread acclaim.

3. Modern Design

It has different pattern designs, including curved, trapezoidal, corrugated, and wavy patterns. This adds different styles to modern buildings.

4. Light Weight

304 Stainless steel corrugated plates are also lightweight, energy-saving, and environmentally friendly. Compared with traditional materials, they are lightweight, easy to transport and install and reduce labor and energy consumption.

5. Heat Resistance

304 Stainless steel possesses remarkable heat resistance properties, enabling it to endure high temperatures without succumbing to warping or compromising its structural integrity. This attribute makes the plate an ideal choice for applications wherein exposure to heat or thermal cycling is a matter of concern, further elevating its desirability.

6. Easy Installation & Low Maintenance

The lightweight feature makes the plate easy to install and tear down, making it loved by countless builders and owners. At the same time, stainless steel materials are recyclable and can be reused after their service life, reducing the waste of resources and having a better protective effect on the environment.

304 Stainless Steel Corrugated Plate’s Common Uses

This plate finds application in different industries due to its excellent resistance to corrosion, durability, and aesthetic appeal. Here we introduce some uses of this type.

1. Construction

In the construction industry, 304 stainless steel corrugated plate is widely used for roofing, siding, wall cladding, coverings, and decoration. Furthermore, its sleek and modern appearance rendered it a popular choice for architectural elements such as facades, handrails, and decorative features. These corrugated sheets can be installed both vertically and horizontally.

2. Automobiles

It is utilized in the manufacturing of exhaust systems, mufflers, and other components that require high heat resistance and corrosion resistance. The material’s durability and ability to withstand harsh conditions make it suitable for automotive applications, ensuring longevity and reliability.

3. Food Processing and Packaging

Its hygienic properties, resistance to corrosion, and ease of cleaning render it an ideal choice for equipment such as tanks, conveyors, and food processing machinery. Additionally, the material is used for packaging applications, including cans, containers, and closures, as it ensures the preservation and safety of food products.

4. Chemical and Petrochemical Industry

304 Stainless steel corrugated plates are also widely used in the field of chemical equipment. They can be used to manufacture storage tanks, pipelines, and reactors that handle corrosive substances.

5. Kitchen Appliances

In terms of kitchen appliances, the high-temperature corrosion resistance of 304 stainless steel corrugated sheets makes it an ideal material for manufacturing kitchen equipment such as stoves and ovens. The stainless steel corrugated plate is not easily deformed by heat, ensuring the normal operation of the equipment.

6. Public Uses

It can also be used in the manufacturing of filtration, shelters, and oil & water separators.

304 Stainless Steel Corrugated Plate Installation

Here we share a general guideline on how to install stainless steel roofing sheets. For more details, you can see our blog: How To Install Corrugated Stainless Steel Sheets?

1. Cut and hem: cut and hem according to the actual size on site before installation.

2. Bottom grooving: the wall uses the base plate bottom, and the top surface uses light steel’ keel bottom, grooving in the corresponding fold position as to install.

3. Install: place the corrugated plate on the bottom, and the plate is fixed with structural glue; The Seam joins together.

4. Reinforce: After the top surface is installed, the stick should be supported and strengthened, which should be removed after the glue is cured.

Care Tips for Maintaining 304 Stainless Steel Corrugated Plate

However, it is also important to maintain the 304 stainless steel corrugated sheets to ensure their longevity and optimal performance.

1. Regular Cleaning and Maintenance

Regular cleaning with mild detergent and warm water is recommended. Then, delicately scrubbing the plate’s expanse with a soft cloth or sponge, always following the direction of the grain. Finally, dry it with a soft and lint-free cloth.

2. Avoiding Abrasive Cleaners and Materials

Take great care to avoid employing abrasive cleaners, scrub brushes, or steel wool as these harsh substances have the potential to inflict scratches or damage upon its otherwise flawless surface. Instead, you can use soft cleaning tools, ensuring the plate’s smooth and polished appearance remains untarnished.

3. Proper Storage and Handling Techniques

Proper storage and handling techniques should also be followed to prevent damage. It should be stored in a clean and dry area, far removed from the perils of moisture or corrosive substances.

4. Asking Professionals for Help

If you have any questions about your stainless steel corrugated plates, feel free to contact us now!