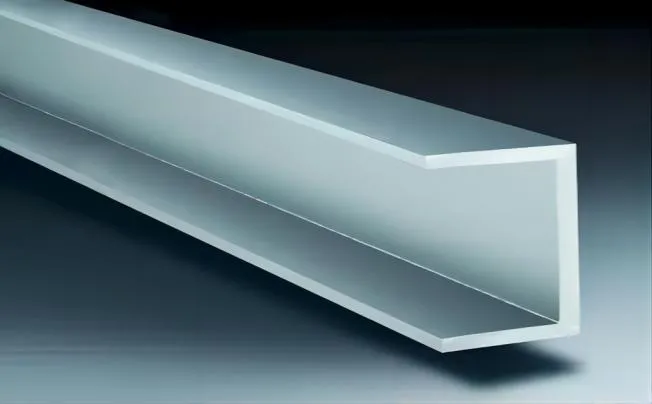

What is a Stainless Steel Channel?

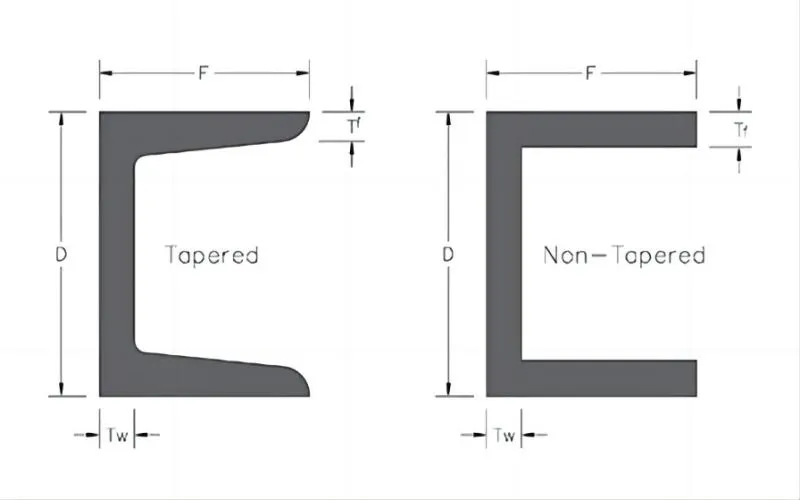

Stainless steel channel steel has a long, groove-shaped cross-section. Similar to I-beams, there are two types of stainless steel channel steel: regular channel steel and light channel steel. Waist circumference (h) × leg width (b) × waist circumference (d), given in millimetres, also serves as an expression for the model and specification. To differentiate, a, b, c, etc. must be added to the right of the model. Hot-rolled structural steel in the shape of a C is used to create stainless steel channel steel, which is then rolled into a U shape with a predetermined radius at the inner corner. The channels are then joined at these angles by butt or lap joints, with a minimum 2-inch (5-cm) overlap.

What is a 304 Stainless Steel Channel?

One kind of stainless steel channel composed of grade 304 stainless steel is called a 304 stainless steel channel. Austenitic stainless steel alloy grade 304, which has 8% nickel and 18% chromium, is widely utilized. It has outstanding formability, is strong at high temperatures, and has exceptional resistance to corrosion. 304 stainless steel is non-magnetic when it is annealed.

Channel made of 304 stainless steel is available in a range of widths and lengths to satisfy project requirements. Cold-processing 304 stainless steel can improve its tensile strength and hardness. However, because of the process’s reduction of carbon content, it might not be as resistant to corrosion in welded construction, where further heat treatment is impractical.

The difference between stainless steel 201 and 304

Different Specifications

15% of 201 stainless steel and 5% of 304 stainless steel are chromium and 9% are nickel, respectively. 201 has a brilliant, black surface. It rusts easily and has a high manganese content. 304 is non-rusting, has a matte finish, and has higher chromium. The variation in nickel concentration is the primary distinction between 201 and 304. Because chromium-rich oxide forms on the surface of the steel body to protect it, stainless steel is resistant to rusting easily. 201 is a low-nickel, high-manganese stainless steel.

Different Components

The quality of 201 is inferior to that of 304. The domestic stainless steel plate 201 is more expensive than the international stainless steel plate 304. Its performance is distinct.

Different Performance

While 201 stainless steel is denser and tougher than 304 stainless steel, it rusts more easily and has significantly less corrosion resistance. There are also differences in the two’s resistance to corrosion. Because 201 is less expensive than 304 due to its lower nickel content and poor corrosion resistance, it is also much less expensive.

Different Applications

While 304 stainless steel has more exceptional and balanced qualities and is widely used in industry, medical equipment, food processing, chemical, and other industries, 201 stainless steel is mostly employed in the domains of decorating and home furnishings.

Applications of 304 Stainless Steel Channel

1. Structural applications: When strength and corrosion resistance are needed, 304 stainless steel channels are frequently utilized in structural applications. In building projects, it offers support and stability for ramps, walkways, and other architectural applications.

2. Industrial equipment: Applications for 304 stainless steel channels in industrial equipment, including those in corrosive conditions, are numerous. It can be used in chemical processing, pharmaceutical manufacture, and industrial transportation due to its great strength and resistance to corrosion.

3. Food industry: 304 stainless steel channels are utilized in the food business because of their excellent corrosion resistance and cleanliness. It is appropriate for uses like food processing and production machinery, where hygienic conditions and cleanliness are crucial.

4. Marine equipment: 304 stainless steel channel can be used in marine construction and equipment because it resists corrosion brought on by the sea.

5. Outdoor uses: Because 304 stainless steel channels are durable and resistant to corrosion, they are utilized in outdoor applications. It is resilient to exposure to a range of weather conditions.

6. Architectural applications: Where strength and visual appeal are crucial, 304 stainless steel channels are utilized in architectural applications. It can be applied to handrails, building facades, and other architectural features for decorative or structural purposes.

7. Custom fabrication: It is simple to construct and modify 304 stainless steel channels to fit particular project specifications. It can be welded into unique shapes and structures after being cut to size.