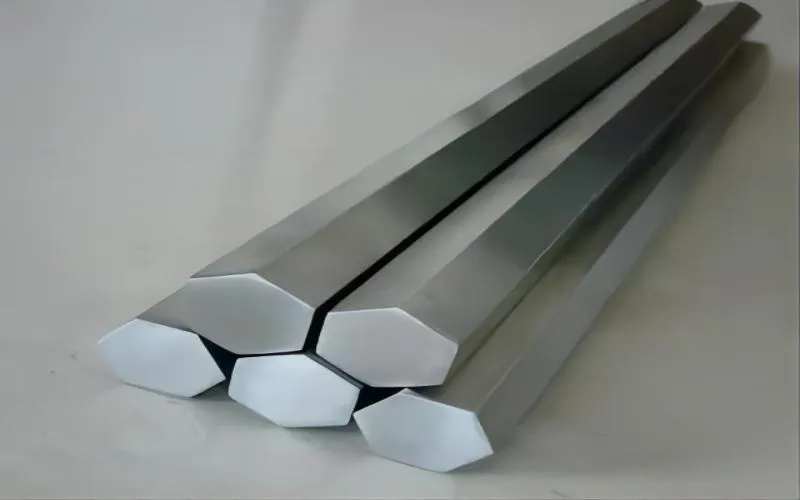

What is a stainless hexagon bar?

A type of stainless steel bar with a hexagonal cross-section is called a stainless hexagon bar, or hexagonal rod. Grades 303 and 316 stainless steel are frequently used to make it. There are a variety of sizes, grades, and finishes of stainless steel hexagon bars available. They can be bought in conventional lengths or cut to order. The hexagon bar’s width and length can be adjusted to meet certain needs.

When it comes to stainless hexagon bars, the two most popular grades are:

type 303: In moderate settings, this type of stainless steel hexagon bar has good corrosion resistance and excellent machining qualities.

Grade 316: Often referred to as “marine grade,” grade 316 stainless hexagon bar is ideal for welding and has outstanding machining characteristics. It also offers excellent corrosion resistance.

What is a 304 stainless steel hexagon bar?

A bar formed like a hexagon and composed of 304 stainless steel is called a 304 stainless hexagon bar. A popular grade of stainless steel with exceptional mechanical qualities and resistance to a wide range of corrosives is 304 stainless steel.

The 304 stainless hexagon bar is helpful in applications where hygiene and cleanliness are crucial since it is non-magnetic after it is annealed. It can be applied to a variety of projects and industries and provides superior corrosion resistance.

Applications of 304 Stainless Hexagon Bar

1. Manufacturing and Machinery: Shafts, fasteners, and bolts are among the machinery components that are made using 304 stainless hexagon bars. They are appropriate for usage in a variety of equipment applications due to their strength and resistance to corrosion.

2. Architectural Uses: Shelves, brackets, and sculptures are just a few of the architectural uses for these hexagon bars. Their distinct shapes give building designs an aesthetic appeal.

3. Food and Beverage business: Equipment, storage tanks, and brewing apparatus are used in the food processing business, where 304 stainless steel hexagon bars are employed. They are appropriate for use in applications involving food because of their resistance to corrosion and hygienic qualities.

4. Plumbing: Pipes, fittings, and fixtures are among the plumbing applications for which these hexagon bars are utilized. They are appropriate for use in plumbing systems due to their longevity and resistance to corrosion.

5. Building: For a variety of structural uses, the building industry uses hexagon bars made of 304 stainless steel. They are appropriate for use in structural components and building frameworks due to their strength and resistance to corrosion.

6. Marine and Coastal Applications: 304 stainless hexagon bars are utilized in marine and coastal applications because of their corrosion resistance. Coastal construction, maritime hardware, and boat fittings are all made with them.

7. Chemical Processing: Applications for these hexagon bars can also be found in chemical processing. They can be used to build tanks, pipes, and valves for use in chemical processing plants because of their corrosion resistance.

Characteristics of 304 Stainless Hexagon Bar

exceptional Mechanical features: High tensile strength, good yield strength, and good hardness are only a few of the exceptional mechanical features of 304 stainless hexagon bars. These characteristics make them appropriate for uses where durability and strength are needed.

Good corrosion resistance is provided by 304 stainless steel hexagon bars in a variety of settings, such as those with moderate corrosive chemicals and airborne pollutants. They are not easily corroded by oxidation, chemicals, or dampness.

Sanitary & Cleanliness: Applications where sanitation and cleanliness are crucial can benefit from the usage of 304 stainless steel hexagon bars. When annealed, they are not magnetic and are readily maintained and cleaned.

Cold Workability: Cold-working 304 stainless hexagon bars can improve their tensile strength and hardness. Their mechanical qualities can be improved by cold working techniques like cold rolling or cold drawing.