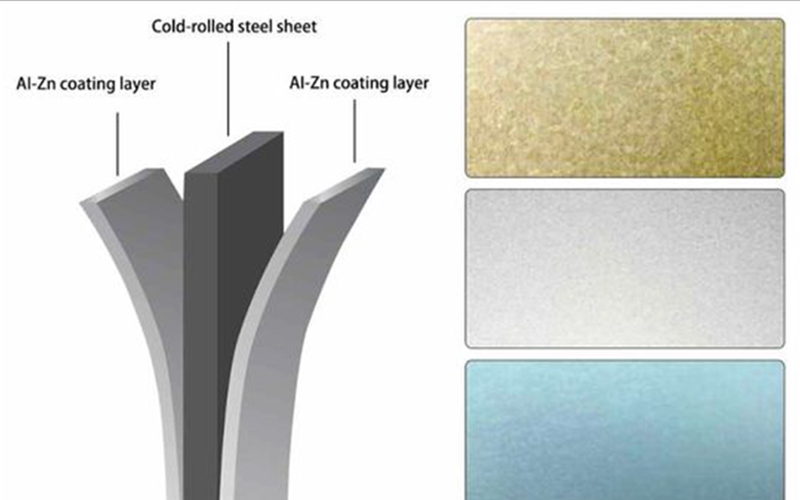

The duplex stainless steel coil is a stainless steel material with a special structure, which is composed of two crystal phases of austenite and ferrite, hence the name duplex stainless steel coil. With chemical raw materials such as chromium, nickel, molybdenum, and nitrogen as the main components, it is made through a specific process. It has excellent properties such as high strength, corrosion resistance, and machinability, and has been widely used in many fields. It is often used in petrochemical equipment, seawater treatment equipment, chemical processing industry, pressure vessels, high-pressure pipelines, food processing equipment, etc. It is an ideal material choice for a variety of harsh environments and engineering scenarios requiring high strength.

Product Specification

Our company’s hot-selling duplex stainless steel coil products include 2205 stainless steel coil and 2507 stainless steel coil. The related products are described as follows:

| Product | 2205 Stainless Steel Coil | 2507 Stainless Steel Coil |

| Main Components | Chromium (Cr): 22-23%

Nickel (Ni): 4.5-6.5% Molybdenum (Mo): 3-3.5% Nitrogen (N): 0.14-0.2% Other elements: Iron (Fe) and small amounts of other alloying elements |

Chromium (Cr): 24-26%

Nickel (Ni): 6-8% Molybdenum (Mo): 3-5% Nitrogen (N): 0.24-0.32% Other elements: Iron (Fe) and small amounts of other alloying elements |

| Main Components | 1000-2000 | 1000-2000 |

| Thickness Range (mm) | 0.3-3.0 | 0.3-3.0 |

| Length Range (m) | Customized according to customer requirements | Customized according to customer requirements |

| Surface Treatment | 2B, BA, NO.1, NO.4, HL, etc. | 2B, BA, NO.1, NO.4, HL, etc. |

| Technical Standards | ASTM A240/A240M, EN 10088-2, JIS G4305, etc. | ASTM A240/A240M, EN 10088-2, JIS G4305, etc. |

The actual product parameters will vary according to specific order requirements. When selecting and purchasing duplex stainless steel coils, please feel free to contact us for more detailed product parameter information. If you have other needs, please also tell us in time, and we will do our best to help you provide suitable stainless steel products.

What Are the Characteristics of Duplex Stainless Steel Coils?

Great qualities of duplex stainless steel include its high strength, outstanding plasticity and toughness, strong corrosion resistance, and great weldability. It is a popular and high-end material option for applications needing great strength and corrosion resistance because of these qualities. The following parts are the important characteristics:

High Strength: Duplex stainless steel has higher yield strength and tensile strength, which is higher than traditional austenitic stainless steel and ferritic stainless steel, and performs well in structural engineering and applications with high strength requirements.

Corrosion Resistance: Duplex stainless steel coils have strong corrosion resistance and can resist a variety of corrosive media, including acidic, alkaline, and chloride environments, and are widely used in chemical, oil, and gas fields.

Excellent Welding Performance: Unlike some other types of stainless steel, duplex stainless steel is relatively easy to weld, and the welded duplex steel still maintains good corrosion resistance and mechanical properties.

Good Plasticity and Toughness: Duplex stainless steel coils maintain good plasticity and toughness while having high strength, and can resist stress and deformation caused by cold working.

How Is Duplex Stainless Steel Coil Made?

The manufacturing process of duplex stainless steel coil mainly includes several steps such as melting and casting, hot rolling, cold rolling, annealing, and pickling:

Smelting and Casting: smelting the raw materials of austenitic stainless steel and ferritic stainless steel to ensure accurate control and uniform mixing of alloy components.

Casting IOnto Slabs: Molten stainless steel alloys are poured into casting molds to form thick slabs. The size and shape of the slab are determined according to the requirements of the product.

Hot Rolling: The slab is heated to an appropriate temperature and then rolled to the desired thickness and width by a series of hot rolling mills. During the hot rolling process, the slab is continuously pressed and elongated to gradually form a hot-rolled coil.

Cold Rolling: The hot-rolled coil is re-pressed and elongated through a cold-rolling mill to reduce its thickness and improve its surface quality, improving the mechanical properties and surface finish of duplex stainless steel coils.

Annealing: Cold-rolled coils are annealed in a controlled high-temperature environment to relieve residual stress and increase the ductility and corrosion resistance of the material.

Pickling: The annealed coil goes through a pickling process, using a pickling solution to clean the surface to remove oxides, welding slag, and other contaminants to achieve a higher surface quality and cleanliness.

Subsequent Processing: Pickled duplex stainless steel coils can be cut, slit, or formed into desired sizes and shapes as required.

Every step in the duplex stainless steel coil manufacturing process plays an important role in the performance and quality of the final product. As an excellent stainless steel supplier, Gnee’s factories can produce high-quality duplex stainless steel coils to meet the needs of various application fields through precise control of each process parameter and strict implementation of quality control standards.

Application Scenarios of Duplex Stainless Steel Coil

Duplex stainless steel coils are widely used in many industries due to their high strength and corrosion resistance properties. Here are some common applications for duplex stainless steel coils:

| Application Field | Example |

| Chemical Processing | Used in the manufacture of chemical processing equipment such as heat exchangers, pressure vessels, and reactors. |

| Oil and Gas Industry | Used in pipelines, valves, and other equipment in offshore oil and gas production to resist corrosion and stress cracking. |

| Seawater Desalination Plant | Due to its excellent seawater corrosion resistance, it is used in the construction of seawater desalination plants, including evaporators and brine coolers. |

| Pulp and Paper Industry | Used in the manufacture of equipment such as digesters, bleach tanks, and evaporators due to its resistance to the corrosive effects of acids and corrosive chemicals. |

| Food Processing Industry | For food processing equipment such as containers, conveyor systems, and processing lines. |

| Construction | A structural material used in buildings and bridges for its structural strength and aesthetic qualities. |

| Automotive Industry | Used in automotive exhaust systems, fuel systems, and chassis components. |

| Medical Industry | For medical equipment and instruments such as surgical instruments, implants, and medical devices. |

| Aerospace Industry | For aerospace devices and structural components. |

The above are just some common application fields of duplex stainless steel coils. If you have this demand, please feel free to contact us. We will provide you with the most professional advice, the most suitable products, and the best service!