Flat Bars: The Foundation of Structural Support and Design

Among the most common types of stainless steel profiles are flat bars. These profiles feature a rectangular cross-section, making them perfect for construction, manufacturing, and architectural applications. Whether it’s for structural support, framing, or adding a touch of elegance, flat bars are the go-to choice.

Round Bars: Unmatched Strength and Machinability

For industries like automotive, aerospace, and marine, round bars are the preferred stainless steel profiles. With their circular cross-section, these bars offer excellent strength and machinability. From shafts to bolts and fasteners, round bars are the backbone of countless applications.

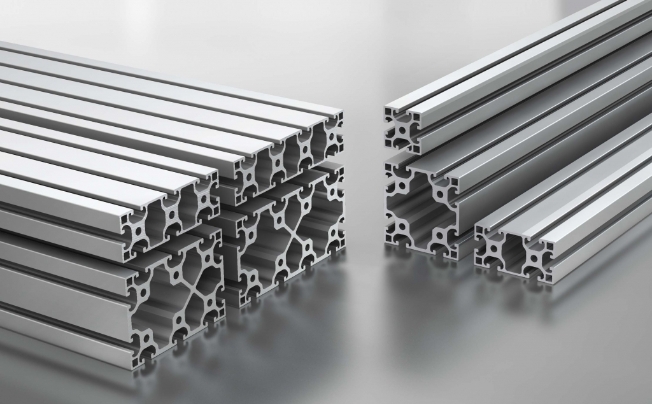

Square Bars: The Key to Stability and Structural Components

When strength and stability are crucial, square bars are the answer. These profiles, with their square cross-section, are frequently used in construction, manufacturing, and engineering projects. Creating structural components, frames, and supports becomes effortless with the use of square bars.

Hexagonal Bars: Grip, Stability, and Precision

Hexagonal bars, with their hexagon-shaped cross-section, provide excellent grip and stability. Industries such as construction, architecture, and machinery rely on these profiles for their manufacturing needs. Whether it’s fasteners, fittings, or precision components, hexagonal bars deliver unmatched performance.

Angle Bars: Reinforcing Corners and Providing Structural Support

Angle bars, also known as L-shaped profiles, are a staple in construction, infrastructure, and architectural projects. With two legs forming a 90-degree angle, these bars are commonly used for structural support, framing, and reinforcing corners. When it comes to stability and reliability, angle bars are the top choice.

Application fields of stainless steel profiles

construction industry

In the construction industry, stainless steel profiles dominate and are the backbone of structural components. From the solid beams that support towering skyscrapers to resilient columns and trusses, these profiles demonstrate unparalleled strength and corrosion resistance. But it doesn’t stop there. Stainless steel profiles also adorn architectural elements, transforming mundane handrails, cladding and facades into stunning masterpieces that will stand the test of time.

Automotive Industry: Driving Excellence

Rev up your engine and buckle up as stainless steel profiles dominate the automotive industry. These profiles play a central role in the manufacture of important components and systems. From creating exhaust systems that can overcome the harshest environments to strengthening fuel tanks with unparalleled corrosion resistance, stainless steel profiles enhance vehicle performance and safety.

Used in manufacturing field

In manufacturing, stainless steel profiles are particularly versatile and provide the backbone for a variety of applications. From machinery and equipment manufacturing to conveyor systems and storage tanks, these profiles provide unparalleled strength, durability and wear resistance. When the going gets tough, stainless steel profiles come to work, ensuring the reliability and longevity of critical production processes.

Food and Beverage Industry

The food and beverage industry requires perfection in all aspects, and stainless steel profiles can exactly meet this requirement. These profiles are the cornerstone of equipment and infrastructure and are carefully crafted to meet strict hygiene and hygiene requirements. From food processing machinery to storage tanks and piping systems, stainless steel profiles maintain product integrity and safety. These profiles are corrosion-resistant, easy to clean and non-reactive, ensuring the careful preparation of your favorite meals.

Aerospace Industry

In the awe-inspiring world of aerospace, stainless steel profiles take flight, defying the most extreme conditions. From structural components that withstand the forces of gravity to engine parts that endure scorching temperatures, these profiles are the epitome of strength, heat resistance, and corrosion resistance. The aerospace industry relies on stainless steel profiles to push boundaries, ensuring exceptional performance and safety at every altitude.

Advantages of stainless steel profiles

Unmatched Corrosion Resistance

One of the standout features of stainless steel profiles is their exceptional corrosion resistance. Whether you’re dealing with moisture, chemicals, or extreme temperatures, these profiles can handle it all. Say goodbye to worrying about rust or degradation. Stainless steel profiles are built to withstand the harshest environments, ensuring that your project remains intact and reliable for years to come.

Durability and Strength

When it comes to structural integrity, stainless steel profiles are second to none. Their durability and strength make them the go-to choice for projects that require long-lasting and reliable materials. With stainless steel profiles, you can say goodbye to frequent repairs or replacements, saving you time, money, and headaches in the long run.

Sleek and Modern Aesthetic

Not only do stainless steel profiles offer unmatched functionality, but they also add a touch of elegance to any project. The sleek and modern look of stainless steel profiles enhances the visual appeal of your creation, leaving a lasting impression on anyone who lays eyes on it. Whether you’re working on a high-end architectural masterpiece or a cutting-edge automotive design, stainless steel profiles will elevate the overall aesthetic and make your project stand out from the crowd.

Easy Maintenance and Cost Reduction

Keeping your project looking pristine has never been easier with stainless steel profiles. These profiles require minimal cleaning and are resistant to staining and discoloration. Say goodbye to tedious upkeep and hello to more time and money in your pocket. With stainless steel profiles, you can focus on what truly matters – bringing your vision to life.

Versatility Across Industries

Stainless steel profiles are the Swiss Army knife of materials, offering versatility that knows no bounds. From construction and architecture to automotive and manufacturing, these profiles can handle any challenge thrown their way. No matter the industry or application, stainless steel profiles are the reliable and flexible choice that will exceed your expectations.

So, why settle for anything less than the best? Choose stainless steel profiles for your next project and experience the game-changing advantages they bring to the table. From unmatched corrosion resistance to a sleek aesthetic, these profiles are the key to success in any endeavor.

Factors to Consider When Choosing Stainless Steel Profiles

When it comes to selecting stainless steel profiles for your project, there are several crucial factors that can greatly impact the overall performance and durability of the material. It’s essential to carefully consider these factors to ensure you make the right choice. Let’s dive into the key considerations that should guide your decision-making process.

Grade of Stainless Steel: Finding the Perfect Match

The grade of stainless steel you choose is of utmost importance as it determines the material’s corrosion resistance, strength, and suitability for different environments. Among the commonly used grades are 304, 316, and 430, each possessing unique properties and applications. To make an informed decision, it’s crucial to thoroughly understand the specific requirements of your project and select the appropriate grade accordingly.

Size and Dimensions: Precision Matters

Size and dimensions play a vital role in the functionality and compatibility of stainless steel profiles with your project. It’s essential to carefully consider factors such as length, width, and thickness, as well as any specific tolerances or customizations required. Ensuring accurate measurements will guarantee a proper fit and optimal performance, saving you from potential headaches down the line.

Surface Finish: Striking the Perfect Balance

While the surface finish of stainless steel profiles significantly impacts their appearance, it also affects their resistance to corrosion and ease of maintenance. You have various options to choose from, including brushed, polished, and satin finishes, each offering different levels of shine and texture. When making your selection, it’s important to strike a balance between the aesthetic appeal and the practical requirements of your project.

Cost and Availability: Balancing Quality and Budget

Cost and availability are crucial factors that should not be overlooked when choosing stainless steel profiles. Different grades and finishes may vary in price, and availability can also depend on the supplier and location. Striking the right balance between your budget and the desired quality is essential. Additionally, ensuring a reliable supply for your project is of utmost importance, as any delays or interruptions can significantly impact your timeline and overall success.

Specific Application Requirements: Tailoring the Perfect Fit

Lastly, it’s essential to consider any specific application requirements that may influence your choice of stainless steel profiles. Factors such as temperature resistance, mechanical properties, or compatibility with other materials can greatly impact the performance and longevity of your project. Seeking guidance from experts or engineers familiar with your project’s needs can provide invaluable insights and help you make an informed decision that aligns perfectly with your requirements.

How to Keep Your Stainless Steel Profiles Gleaming and Rust-Free

When it comes to durability and resistance to corrosion, stainless steel profiles are hard to beat. That’s why they’re a popular choice for a wide range of applications. But to ensure their longevity and keep them looking their best, regular cleaning and maintenance practices are a must. In this guide, we’ll walk you through the essential steps for maintaining your stainless steel profiles, from avoiding harsh chemicals and abrasives to removing stains and rust.

Regular Cleaning and Maintenance Practices: A Gentle Touch is Key

Regular cleaning is the foundation of stainless steel profile maintenance. Start by mixing a mild detergent or soap with warm water. Grab a soft cloth or sponge and gently scrub the surface, always following the grain of the stainless steel. Rinse thoroughly and dry with a clean cloth to prevent unsightly water spots or streaks. While cleaning, keep an eye out for any signs of damage, such as scratches or dents, and address them promptly to avoid further issues.

Avoiding Harsh Chemicals and Abrasives: Protecting the Integrity of Your Profiles

When it comes to cleaning stainless steel profiles, it’s crucial to steer clear of harsh chemicals and abrasives. These can cause irreparable damage to the surface and compromise its corrosion resistance. Instead, opt for mild cleaning solutions or specialized stainless steel cleaners that are specifically formulated for this purpose. Always read the manufacturer’s instructions and test any new cleaning product on a small, inconspicuous area before applying it to the entire profile.

Proper Storage and Handling: Shielding Your Profiles from Unwanted Blemishes

Proper storage and handling play a pivotal role in maintaining the appearance of your stainless steel profiles. Keep them in a clean and dry environment, away from direct sunlight and excessive moisture. Avoid stacking or placing heavy objects on top of the profiles to prevent unsightly scratches or deformation. And when it’s time to handle the profiles, make sure to use gloves or a clean cloth to avoid leaving fingerprints or oils on the surface.

Removing Stains and Rust: Swift Action for a Spotless Shine

If stains or rust rear their ugly heads on your stainless steel profiles, swift action is necessary to prevent further damage. For light stains, create a mixture of vinegar and water and gently scrub the affected area. For more stubborn stains, whip up a paste made of baking soda and water, apply it to the stain, and let it sit for a few minutes before scrubbing. And when it comes to rust, a specialized stainless steel rust remover is your best bet. Just be sure to follow the manufacturer’s instructions to the letter.

Polishing and Restoring the Shine: Unleash the Inner Glow of Your Profiles

To truly bring out the shine in your stainless steel profiles, regular polishing is a must. You can achieve this by using a stainless steel polish or a mixture of olive oil and vinegar. Simply apply the polish or mixture to a soft cloth and gently rub the surface in circular motions. Wipe off any excess polish and buff the profile to a brilliant shine. Not only will this enhance its appearance, but it will also provide an added layer of protection against future stains and corrosion.

Frequently Asked Questions about Stainless Steel Profiles

What are stainless steel profiles?

Stainless steel profiles are various shapes and sizes of stainless steel bars that are used in different industries for their durability, corrosion resistance, and aesthetic appeal.

What are the different types of stainless steel profiles?

The different types of stainless steel profiles include flat bars, round bars, square bars, hexagonal bars, and angle bars. Each type has its own unique characteristics and applications.

What are flat bars used for?

Flat bars are commonly used in construction, manufacturing, and architectural applications for structural support, framing, and adding elegance to a project.

What are round bars used for?

Round bars are preferred in industries like automotive, aerospace, and marine for their strength and machinability. They are used for shafts, bolts, and fasteners.

What are square bars used for?

Square bars are frequently used in construction, manufacturing, and engineering projects for their strength and stability. They are used to create structural components, frames, and supports.

What are hexagonal bars used for?

Hexagonal bars provide excellent grip and stability and are used in industries such as construction, architecture, and machinery for manufacturing fasteners, fittings, and precision components.

What are angle bars used for?

Angle bars, also known as L-shaped profiles, are commonly used in construction, infrastructure, and architectural projects for structural support, framing, and reinforcing corners.

What industries benefit from stainless steel profiles?

Industries such as construction, automotive, manufacturing, food and beverage, and aerospace benefit from the use of stainless steel profiles for their strength, durability, and resistance to corrosion.

What are the advantages of stainless steel profiles?

Stainless steel profiles offer unmatched corrosion resistance, durability, a sleek aesthetic, easy maintenance, and versatility across industries.

What factors should be considered when choosing stainless steel profiles?

Important factors to consider when choosing stainless steel profiles include the grade of stainless steel, size and dimensions, surface finish, cost and availability, and specific application requirements.

How should stainless steel profiles be maintained?

Regular cleaning with mild detergent or soap and warm water, avoiding harsh chemicals and abrasives, proper storage and handling, and swift action to remove stains and rust are key to maintaining stainless steel profiles. Polishing can also restore their shine.