What is 304 Stainless Steel Pipe?

One kind of stainless steel pipe that is frequently utilized in many different sectors and applications is 304 stainless steel pipe.

The following are some essential qualities and attributes of 304 stainless steel pipe:

1. Corrosion resistance: 304 stainless steel pipe has strong resistance to corrosion from a variety of chemicals and from industrial environments.

2. Strength: Because of its great strength, it can be used in structural applications.

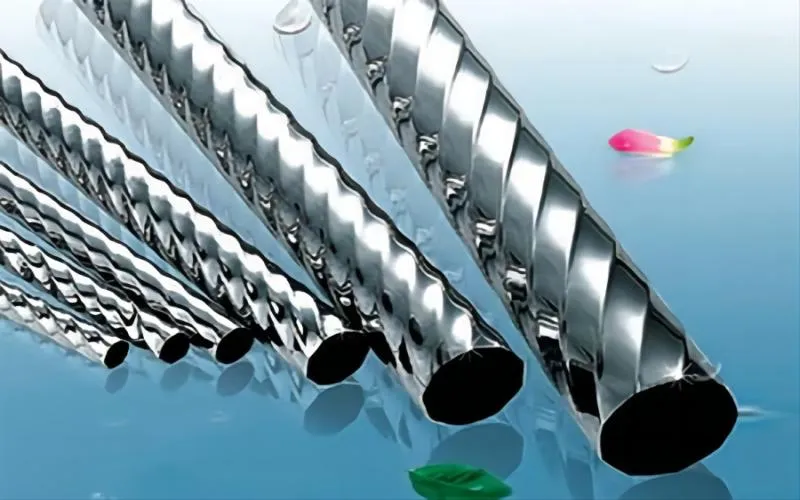

3. Formability: 304 stainless steel tubing is incredibly formable, making it simple to shape and weld using standard techniques.

4. Versatility: This grade of stainless steel is adaptable and can be used in a variety of settings, such as machinery, food and beverage, aerospace, chemical, and cryogenic applications.

5. Weldability: 304 stainless steel pipe easily undergoes welding, either with or without the addition of filler metal.

6. Surface finish: It usually has an inside welded seam and a sturdy mill finish. A brushed polish could also be available in some sizes.

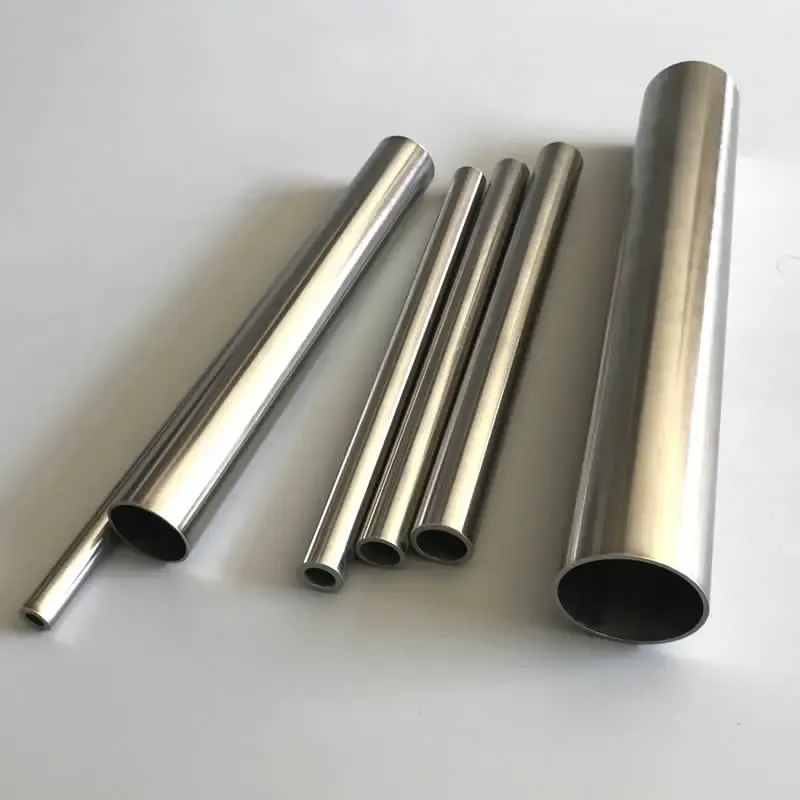

7. Availability: Custom lengths can be cut from 304 stainless steel pipe, which comes in a range of diameters.

Why Do Identical 304 Stainless Steel Pipes Cost Different Amounts?

There are a number of reasons why similar 304 stainless steel pipes cost different amounts. The particular industry or use for which the pipes are intended is one of the primary determinants. The price of stainless steel pipes may vary depending on the standards and requirements of various sectors. For instance, 304 stainless steel pipes are frequently utilized in high-rise building water supply systems because of their excellent corrosion resistance and resilience to high pressure.

The quality of stainless steel that is utilized might also have an impact on the cost differential. Although 304 stainless steel is the most commonly used type, other grades are also available, including 316 stainless steel. Better corrosion resistance than 304 stainless steel makes 316 stainless steel appropriate for use in chemical and pharmaceutical applications as well as marine conditions.

In addition, variables including market demand, quality control procedures, and the production process may also affect how much 304 stainless steel pipes cost differently from one another.

Other Factors Affecting 304 Stainless Steel Pipe

Premium 304 stainless steel pipe: Baosteel, Taigang, and Qingshan are only a few of the significant steel facilities from which the raw materials are sourced. There is an adequate and uniform distribution of element content, rigorous testing, and no omission of processing steps. Customers with higher criteria, such as state-owned enterprise projects and exports, typically buy them.

Mid-range stainless steel pipe made of 304: Medium-sized steel factories provide the majority of the raw materials, which have an adequate element composition. Although the processing method is not as rigorous, the mechanical qualities can be met.

Low-end 304 stainless steel pipe: Because the production process is “streamlined” and the raw materials are primarily recycled or tiny furnace materials, the price is low. Because kitchens smell more like smoke and bathrooms are more humid, it is primarily used in these spaces. To guarantee that stainless steel goods do not rust, 304 stainless steel must be utilized in these two locations.

High-rise building water supply: 304 stainless steel pipes are the best material for high-rise building water supply systems since they are prone to leaking when subjected to external forces. Conventional high-rise building water supply systems operate under high pressure. 304 stainless steel pipes are required for coastal areas due to the wind and corrosion. 201 pipes made of stainless steel will corrode rapidly.

In conclusion, variables including the particular application or industry, the grade of stainless steel utilized, the production process, quality control procedures, and market demand may all be blamed for the variation in price for the same 304 stainless steel pipe.