What Do You Need to Know About Stainless Steel Decorative Pipes?

1. Corrosion Resistance: Excellent corrosion resistance is one of stainless steel‘s best qualities. Therefore, stainless steel decorative pipes have great anti-rust, anti-fouling, and anti-corrosion qualities and are strong, long-lasting, and durable.

2. High-temperature Resistance: Decorative stainless steel pipes can tolerate high temperatures without warping or being damaged.

3. High Strength and Durability: Stainless steel decorative pipes are sturdy and resilient and can handle a variety of mechanical and environmental conditions. They are designed to hold up to daily use while maintaining their structural integrity.

4. Flexibility: The availability of stainless steel decorative pipes in a range of shapes, sizes, and finishes allows for design flexibility. They are easily incorporated into various architectural styles and can be tailored to fit individual project requirements.

5. Simple to keep clean and resistant to dirt, grime, and fingerprints: The stainless steel trim pipe is simple to clean. To keep it looking good, daily washing with mild soap and water is usually sufficient.

6. Hygienic: Stainless steel is naturally hygienic, and decorative pipe made of it is also naturally hygienic and healthy. As a result, it is appropriate for applications where cleanliness is essential, such as food processing facilities, hospitals, and laboratories.

7. Aesthetic Appeal: Stainless steel decorative pipes are extensively used in the construction and decoration industries, have a sleek and contemporary appearance, and are especially created to enhance the visual appeal of the space.

8. Environmentally Friendly: Because stainless steel is a recyclable material, it is a sustainable material and a good option for the environment.

How is the Stainless Steel Decorative Pipe Produced?

Each step of the manufacturing process reflects the high caliber of the stainless steel pipe. Let’s briefly go over how stainless steel decorative pipes are made in our factory.

- Material Choice

Steel strips from refining furnaces should be used to create premium stainless steel decorative pipes. The stainless steel pipe created in this manner has good corrosion resistance, is soft, brilliant, and has flawless welds. Additionally, it is more practical for complex operations like pipe bending and welding, and product quality is ensured.

- Calendar

You must first choose the strip steel, and then you must decide on the rolling manufacturer. The completed stainless steel decorative pipe’s thickness and precision of unit weight are strongly correlated with the rolling process’ quality. This has a significant impact on how much agents and processors are charged.

- Creating Pipes

This process plays a crucial role in the creation of stainless steel pipes. To avoid misleading customers and to make them feel more at rest, our manufacturers would print the steel seal first, indicate the specification and true thickness of the pipe on the pipe body, and inform all users that their stainless steel employs a solid standard thicker steel seal.

- Internal Weld Seam Protection

Our stainless steel pipe companies do a specific treatment that involves adding nitrogen internal protection while welding. To prevent the stainless steel pipe weld from breaking and rusting during subsequent use, oxygen is blocked during the welding process and nitrogen is supplied to create a white line at the inner weld. This technique ensures the pipe’s quality.

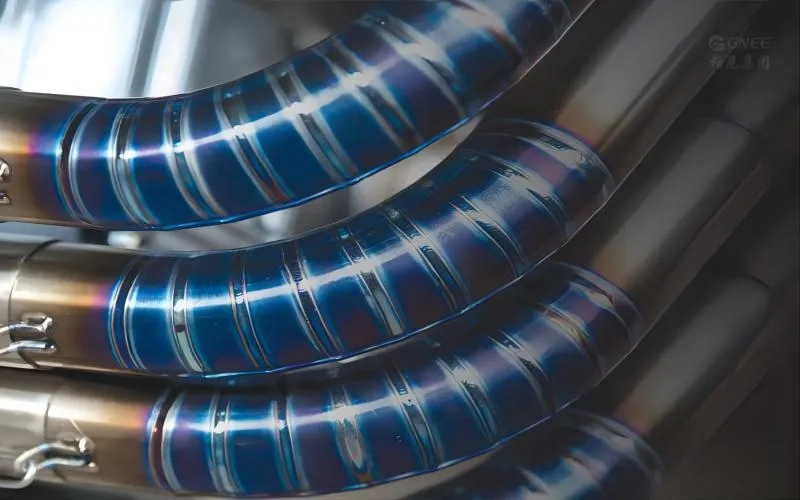

- Adding Polish

Not just the quality of the raw materials but also the chosen polishing materials and the skill of the polishing master have an impact on the brightness of stainless steel decorative pipes.

- Packaging

The final stainless steel pipes should be cleaned, and have anti-counterfeiting labels applied, and each shipment should have a certificate of conformity.

- Storage Facility

The stainless steel decorative pipe should be kept separate from other metal elements in a specific storage rack to prevent scratches or contamination of the surface. When storing, the position should be easy to hoist into and away from other material storage spaces, and precautions should be taken to avoid contaminating the stainless steel decorative pipe with dust, oil, or rust.

What Industries Are Stainless Steel Decorative Pipes Used in?

In practically every place where metal is used in daily life, such as stainless steel railings, guardrails, anti-theft doors and windows, and so forth, there are stainless steel decorative pipes. Additionally, display racks, stainless steel table legs, seats, and other items are used in shopping malls. There are many stainless steel decorative pipe parts even though certain goods don’t primarily consist of decorative stainless steel pipes.

Stainless steel decorative pipes are also uncommon and do not meet the specifications for stainless steel pipes used in industry. While stainless steel decorative pipes are welded pipes, industrial pipes are essentially stainless steel seamless pipes. Therefore, stainless steel decorative pipes are essentially not used in industrial pipes.

The maintenance approach, incidentally. Because stainless steel decorative pipe is a type of corrosion-resistant steel, we can frequently clean it if we use it with a little care. In general, use water alone to clean rather than corrosive substances. If there are a few rust stains from environmental use, don’t be concerned; simply massage the stainless steel decorative pipe with antirust oil a few times vigorously. In general, rust stains won’t be visible in great quantities on this material. Large spots of rust indicate a concern with the product’s quality.