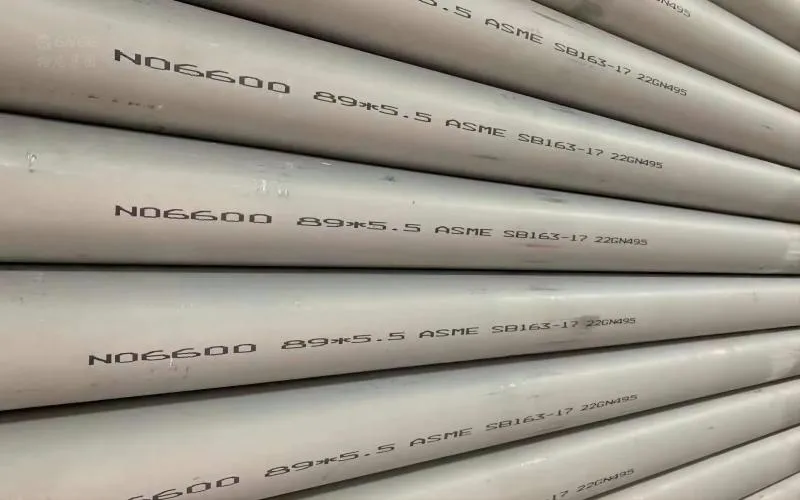

What is a Solid Stainless Steel Pipe?

Pipes manufactured from a single piece of stainless steel material without any seams or welds are referred to as solid stainless steel pipes. Stainless steel is often produced by an extrusion process in which a solid block or billet is converted into a hollow tube.

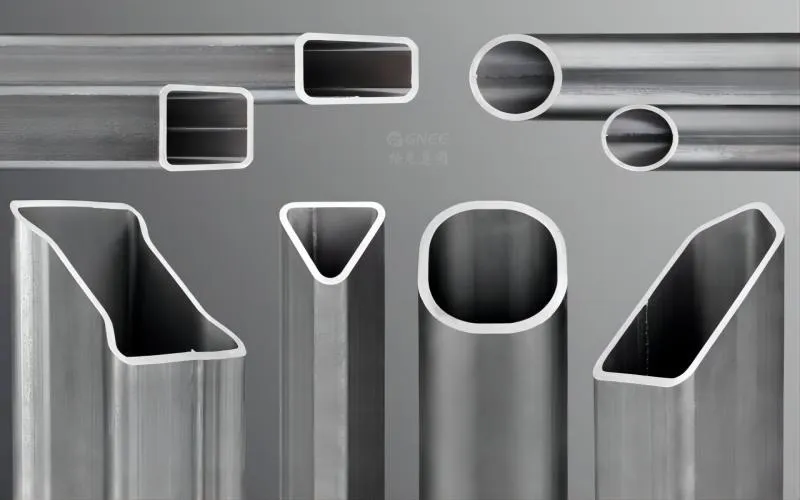

What is a Hollow Stainless Steel Pipe?

A stainless steel pipe is said to have a hollow interior when it has a cylindrical shape. It is frequently utilized in a variety of fields and situations where the movement of fluids or gases is necessary. Depending on the intended specifications and requirements, different manufacturing processes, such as extrusion or roll-forming, are used to produce hollow stainless steel pipes.

Advantages of Solid Stainless Steel Pipe

1. Strength and Durability: Solid stainless steel pipes are renowned for their strength and longevity because they can survive harsh conditions such as high pressure, high temperature, and corrosive environments.

2. Uniformity and Consistency: Because these pipes are made from a single piece of stainless steel, their size and performance are constant along the whole length of the pipe, assuring consistent performance.

3. Better Flow Properties: Smooth inner surfaces of solid pipes lower friction and enhance the flow of liquid or gas through the pipe.

4. Corrosion Resistance: Stainless steel has a natural corrosion resistance. Solid stainless steel pipes are frequently employed because of their remarkable resistance to many corrosive chemicals.

5. Simple to Maintain: Because of their smooth surface and resistance to corrosion, solid stainless steel pipes are generally simple to clean and maintain.

Properties of Hollow Stainless Steel Pipe

1. Construction and design: Hollow stainless steel pipes are constructed with an internal hollow tube and are intended to serve as pipelines for the transmission of liquids, gases, or other substances.

2. Available in a range of sizes: Hollow stainless steel pipes come in a range of outer diameters (OD), wall thicknesses, and lengths. To meet the needs of a particular application, these criteria can be altered.

3. Uses: Stainless steel hollow pipes are employed in different industries, including manufacturing, oil and gas, chemical processing, construction, and oil and gas. They are frequently utilized in applications requiring corrosion resistance and endurance, such as fluid transfer, structural supports, heat exchangers, and others.

4. Available in a variety of grades and alloys, including 304, 316, 321, and 309, stainless steel pipes are available in a variety of grades and alloys. The choice of grade is influenced by characteristics like corrosion resistance, temperature resistance, and mechanical requirements for the particular application.

5. Seamless or welded: Hollow stainless steel pipes can be created either way during manufacturing. While welded pipes are made by rolling and welding stainless steel plates or coils, seamless pipes are made from solid stainless steel billets using an extrusion process.

6. Stainless steel is well renowned for its outstanding corrosion resistance. Hollow stainless steel pipes are useful for use in hostile settings because they can withstand a variety of corrosive substances.

What is the Difference Between Solid Stainless Steel Pipe and Hollow Stainless Steel Pipe?

A solid stainless steel pipe and a hollow stainless steel pipe differ primarily in terms of structure and design.

An uninterrupted, solid cross-section runs the length of a solid stainless steel pipe. It is frequently employed in applications where fluid or gas flow is not necessary and does not have an empty interior. When strength is a necessity or for structural considerations, solid stainless steel pipes are frequently employed.

On the other hand, a hollow stainless steel pipe has a hollow interior and a tubular framework. It is made to act as a conduit for the passage of gases, liquids, and other materials. Hollow stainless steel pipes are frequently utilized in a variety of fields and situations where gas or liquid flow is required, including plumbing, heat exchangers, oil and gas pipelines, and more.