Meet Stainless Steel Slit Coils

Depending on the application, different manufacturers prefer different product forms, from sheet to coil, plate, rod, wire, and pipe. A stainless steel slitting coil is a stainless steel product obtained by cutting stainless steel coils according to certain specifications and sizes. It can minimize the waste of stainless steel coils, save costs, meet the needs of different applications, and facilitate packaging and purchasing of stainless steel materials.

Definition of Stainless Steel Coil Slitting

Stainless steel coil slitting refers to the process of cutting stainless steel coils according to certain specifications and sizes through special equipment such as stainless steel slitting machines.

Stainless steel begins as a large sheet of metal that is rolled to thinner gauges and rolled into stainless steel coils. These large and wide coils are called main coils, which are then cut into narrower widths, cut into strips or sheets to meet the requirements of manufacturing and process needs.

Why Do You Need Stainless Steel Coil Slitting?

Stainless steel coil slitting is a key process whose importance lies in meeting specific needs and providing more flexibility.

Imagine that when you install stainless steel pipes in a building or make stainless steel parts of a certain size, the material required must be accurate to the millimeter. However, stainless steel coils are usually wide and long, which makes it difficult to meet the needs. At this time, the slitting process can cut them into precise sizes and specifications to ensure a perfect fit for your project needs.

Slitting allows you to cut the coil into smaller, more manageable strips or sheets. It makes processing more convenient and provides more options for storage.

More importantly, stainless steel is a precious material, and it is a 100% reusable alloy product, any waste may increase the cost. Slitting ensures you only buy and use what you need, reducing waste and additional costs.

Coil Slitting Process

The stainless steel coil slitting process involves three basic steps, each of which plays a critical role in obtaining accurate, high-quality strips.

1. Stainless Steel Coil Uncoiling

Coil slitting begins with stainless steel uncoiling. Stainless steel decoiling, also known as stainless steel coil decoiling, is an important pretreatment process that is usually used in the manufacturing industry to process raw coils of stainless steel coils. To make it suitable for further processing, it needs to be unrolled and flattened. This step ensures that the metal is in a manageable state.

2. Cutting

After the stainless steel coil is uncoiled and flattened, the next step is cutting. Often precision instruments such as slitters are required to ensure precise and consistent cuts. This step directly affects the final dimensions and tolerances of the strip.

3. Recoil

After the stainless steel coil is cut into strips, the recoiling process begins. This involves rolling the metal strip back into a coil shape. The coiler is a critical component in maintaining the integrity of the strip and ensuring it is evenly and tightly wound.

Stainless steel coil slitting is a delicate process including decoiling, precision cutting, and recoiling. Each step must be performed precisely to produce a high-quality stainless steel strip that meets specific tolerances and requirements. In an industry where precision is critical, it is unacceptable that any misalignment or deviation could result in an inaccurate final product.

Additional Process after Coil Slitting

1. Deburring

During the cutting process, burrs may be generated on the edge of the slit stainless steel coil. To ensure that the edges are smooth and smooth, a deburring process can be used for treatment. Deburring can remove the burrs and sharp parts of the edge by mechanical polishing, scraper, grinding wheel, and other methods.

2. Surface Treatment

Surface treatment can be carried out by pickling, galvanizing, painting, and other processes, which can improve the corrosion resistance of stainless steel coils and are suitable for different application requirements.

3. Annealing Treatment

In some cases, stainless steel coils may require annealing treatment. Annealing can be carried out by heating the steel coil to a certain temperature and then cooling it slowly to relieve stress and improve the machinability and mechanical properties of the steel.

The use of additional processes can improve the performance of stainless steel coils, but not every roll of stainless steel coils requires each of the above additional processes after slitting. The specific operation steps and processes should be adjusted and optimized according to the actual situation. Choose the appropriate method and follow the appropriate safe practice.

Custom Steel Coil Slitting Services

When it comes to needing to meet specific project needs, our company, GNEE Steel, offers a professional custom coil slitting service. No matter what stainless steel coil your project calls for, we can precisely cut the strip or sheet to fit your needs, based on your specifications and size requirements. We have advanced cutting equipment and an experienced professional team to ensure that every order can be handled carefully. Choose us, you will get high-quality stainless steel coils, improve engineering efficiency, reduce stainless steel waste, and reduce costs. Let us work together to provide superior stainless steel solutions for your projects.

View more products with one click —>

Identifying the Highest Quality Stainless Steel Coils

How can you be sure that the stainless steel coils you get are of the highest quality? Follow me as I learn some key points to help you identify and select the best quality stainless steel coil.

1. Material Grade

The first thing to know is the material grade of stainless steel. There are many types of stainless steel, and the chemical composition and physical properties of different grades of stainless steel are different. For example, the common ones are 304, 316, 430, and so on. Make sure the grade of material you choose meets your needs.

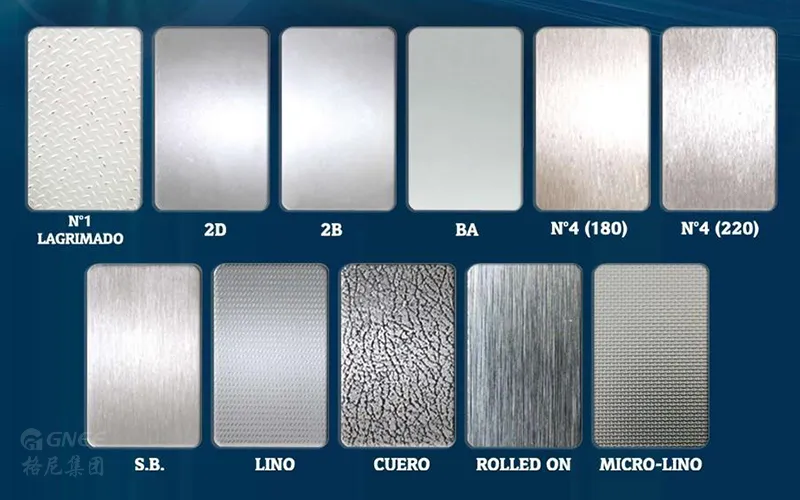

2. Surface Quality

A high-quality stainless steel coil should have a smooth, uniform, and clean surface, and the surface quality is directly related to its performance and aesthetics. Inspect the surface of the coil for scratches, dents, stains, or other obvious defects.

3. Dimensions and Tolerances

Make sure the dimensions and tolerances of your stainless steel coil meet your project requirements. High-quality suppliers usually offer tighter dimensional control to ensure that the rolls can be perfectly adapted to your project.

4. Corrosion Resistance

One of the main characteristics of stainless steel is its corrosion resistance. If your coil will be used in a harsh environment, then consider the corrosion resistance of stainless steel to ensure that you choose the stainless steel material that is suitable for your application environment.

5. Certification and Testing

Finally, to know whether the stainless steel coil has passed the relevant certification and test, you can also take the sample and send it to the relevant organization for random inspection. High-quality coils are subjected to various tests to verify their quality and performance.

Buying Stainless Steel Steel Coil?

GNEE Steel Group is a professional supply chain enterprise, mainly engaged in the design and processing of steel plates, coils, profiles, and outdoor landscapes. After 15 years of development, it has become a leading international steel supply chain company in the Central Plains.

In addition to stainless steel coils, the products currently sold include stainless steel tubes, stainless steel foils, stainless steel sheets, etc., with various models.

If you have needs in this area, please contact us for consultation, we will provide you with the most professional advice, the most suitable products, and the best service! GNEE is always waiting for your presence.