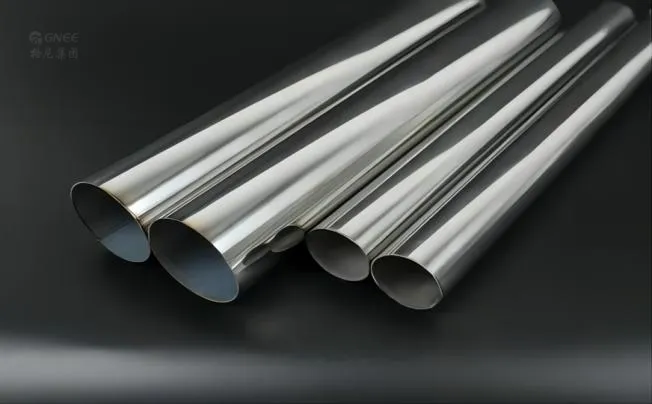

Common Cutting Stainless Steel Pipe Methods

1. Abrasive cutting

Grinding wheel cutting is a popular and efficient way of cutting stainless steel pipes. It involves using a high-speed revolving grinding wheel. Although it can precisely and swiftly cut stainless steel pipes, the finished product will have some burrs at the end. Better outcomes can be obtained using a stainless steel pipe deburring machine or the appropriate and efficient deburring technique.

2. Cutting with a circular saw

Although circular saw cutting produces no burrs, it is more expensive than automatic cutting equipment due to the increased labor expenses. However, it can be used to cut some longer stainless steel pipes.

3. Laser engraving

With laser cutting, the stainless steel is melted and evaporated using the energy created when the laser irradiates the surface. There is a lot of concentrated energy, quick heating, quick cutting, and good cutting quality. It can cut stainless steel materials with a variety of intricate shapes with accuracy and efficiency, and the ensuing processing expenses are minimal. Nevertheless, because of their high cost, laser-cutting machines are best suited for large-scale manufacturing operations.

4. An autonomous cutting device

The automatic cutting machine’s cutting result is similar to that of laser cutting, and it is reasonably priced. No labor is needed, but it is best suited for cutting small sizes because if the size is too lengthy, the machine’s gearbox would lag.

5. Chopping hogs

When cutting using a hob cutter, the result is a smooth cut free of burrs, saw teeth, and sharp edges. It is a popular and useful technique for small and medium-sized businesses to cut stainless steel. To improve edge problems, though, more processing is needed.

6. Cutting wire

The quick wire-cutting technique produces clean, burr-free slices. Pipelines made of stainless steel, however, could somewhat discolor after cutting and need to be ground and polished again. The procedure is difficult, wasteful, and unfit for general usage.

7. Using plasma

Ion gas is used with automatic plasma cutting equipment to create high-temperature, quickly melting stainless steel that can be cut quickly. After cutting, some metal residue will still be present on the inner wall of the stainless steel pipe, necessitating further cleaning. Furthermore, the stainless steel mouth will be somewhat discolored and the cutting will not be smooth after using a plasma cutting machine, which can easily lead to issues with the cutting quality.

What Are the Stainless Steel Pipe Cutting Equipment?

Metal and plastic pipe-cutting tools are the two main categories of pipe-cutting tools. These include split beveling machines, rotary pipe cutting knives, articulated pipe cutting knives, pipe climbing pipe cutting and beveling machines, and metal pipe cutting machines under 2 inches. Plastic pipe-cutting tools can also be separated into three sections: the rotating plastic pipe-cutting machine, the PE pipe guillotine, and the PE pipe scraper.

Metal Pipe Cutting Knife

1. Metal Pipe-Cutting Machine Below 2 Inches

Cast iron, carbon steel, and stainless steel pipes can all be cut with the expert cold cutting tool known as the metal pipe cutting machine ECG2 below 2 inches. The cutting edge is straight and all four blades run in a straight line thanks to the employment of a spring guide frame. Cutting is quick and labor-saving because of the high-strength tool steel used to make the thin, sharp blade. This pipe-cold-cutting tool is the fastest available on the market. Because cutting with a sharp blade is more labor-saving, the pipe cutter’s handle may be made shorter, making it ideal for usage in cramped areas.

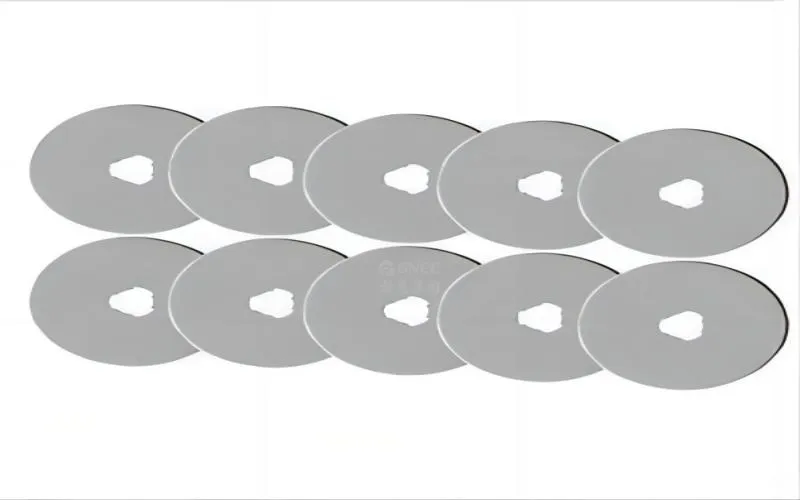

2. A Rotary Blade Cutter

Professional cold-cutting instruments that can cut large-diameter pipes made of carbon steel, stainless steel, cast iron, and ductile iron are the rotary pipe-cutting machine series. Pipe cutting is more efficient and labor-saving thanks to the ultra-reasonable body design and intelligent structural settings! High-strength tool steel is used to make the cutting blade. The strength and toughness of the blade are balanced after a unique heat treatment process, ensuring that it cuts rapidly and is long-lasting.

3. A Machine That Cuts Pipes Articulated

Professional cold-cutting instruments that can cut carbon steel, stainless steel, cast iron, and ductile iron pipes are the articulated pipe-cutting machine series. The cutting performance is further enhanced by the ultra-light body design and sensible structural settings. High-strength tool steel is used to make the cutting blade. To balance the blade’s strength and toughness and ensure that it cuts rapidly while still being strong and resistant to wear, it has undergone a unique heat treatment.

4. A Pipe Cutting and Beveling Machine of the Pipe Climbing Type

The power source for the pipe-climbing type of pipe-cutting and beveling machinery is hydraulic pressure. The cutting and beveling tool is powered by hydraulic pressure and operates on the same cutting principle as a disc milling cutter. To finish the pipe-cutting and beveling operation, the cutting robot is remotely controlled to crawl around the pipe’s perimeter. First, it gently feeds through the threaded screw to cut through the pipe that has to be cut. Pipes having exterior diameters ranging from 6 inches (153mm) to 72 inches (1829mm) can be processed by it.

5. A Machine for Splitting and Beveling

Equipment for splitting and beveling adheres to the necessary norms and laws for gas, petroleum, and petrochemical firms as well as the needs of the relevant industries. Pipeline cutting and beveling maintenance in mining and industrial businesses, including gas, petroleum, and petrochemicals, is appropriate for this equipment. Installing and repairing this equipment is essential for users. It works well in a variety of operational situations, including small spaces, trenches, combustible and explosive areas, and areas where noise is prohibited.

Plastic Pipe Cutting Tools

1. A PE Pipe Cutter

Products in the PE pipe guillotine series are expert cutting instruments designed to cut PE pipes. The guillotine’s structure is reasonable and uncomplicated. High-strength ductile iron, which has the technical benefits of strong ductility and high strength, is used to make the fuselage. It is resistant to falling and smashing, in addition to deforming under stress. To create a balance between the blade’s strength and toughness, a unique heat treatment process is used for high-strength tool steel. Teflon coating is also applied to the blade’s surface, guaranteeing rapid cutting along with durability and resistance to wear. At the moment, it works well as a cutting tool to cut PE pipes.

2. A Rotating Machine for Cutting Plastic Pipes

Professional cutting instruments that can cut PE pipes are the rotary plastic pipe cutting machine series. This product has a sensible and straightforward structure. Aluminium alloy casting, which offers the technological benefits of high structural strength and lightweight, is used to make the body. PVC or PE pipes only need 6 to 8 inches of working space around them, making them ideal for work pits and ground-cutting applications. To guarantee straight cutting, the pipe-cutting machine is adjusted with the aid of the roller. Concurrently, the pipe-cutting machine may bevel the pipe mouth on both the inside and outside by 15 degrees.