What Are the Different Types of Stainless Steel Plates?

Generally speaking, stainless steel plates can be divided into different variants in terms of thickness, manufacturing process, stainless steel organization, surface, performance, function, etc. Let’s see below.

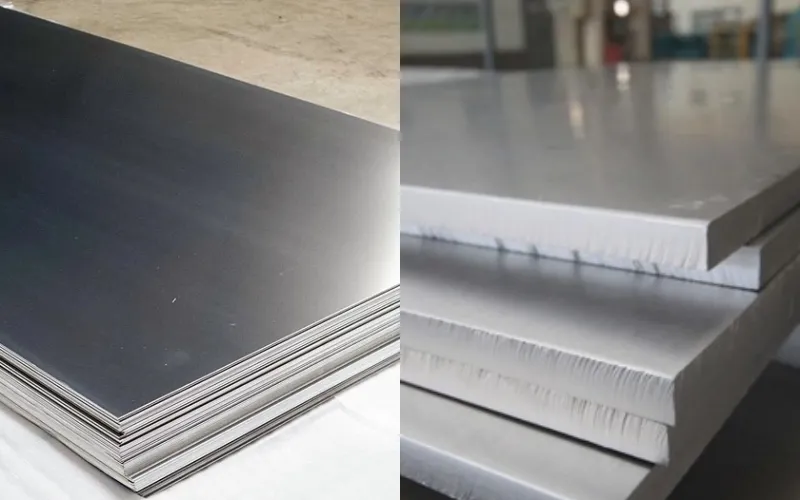

Thickness

According to the thickness classification, there are mainly four types of stainless steel plates:

Ultra-thin stainless steel sheet: <0.2mm

Thin stainless steel sheet: 0.2mm-4mm

Medium-thick stainless steel plates: 4mm-20mm

Thick stainless steel plates: 20mm-60mm

Ultra-thick stainless steel plates: 60mm-115mm

Stainless Steel Organization

According to the stainless steel organization, there are austenitic, ferritic, martensitic, duplex, and precipitation-hardening stainless steel plates.

Austenitic Stainless Steel Plates: the most commonly used type of stainless steel plates. It contains a high amount of chromium and nickel, which gives it excellent corrosion resistance and makes it non-magnetic. 304 and 316 are two popular austenitic grades used in a wide range of applications including harsh and marine environments.

Ferritic Stainless Steel Plates: contain chromium and have a ferritic microstructure, which makes them magnetic. Ferritic stainless steel plates offer commendable corrosion resistance and are commonly used in automotive applications and decorative purposes.

Martensitic Stainless Steel Plates: known for their high strength and hardness. It contains chromium, nickel, molybdenum, and carbon, which contribute to its unique properties. Martensitic stainless steel plates are often used in applications that require high wear resistance, such as cutlery, surgical instruments, and turbine blades.

Duplex Stainless Steel Plates: a combination of austenitic and ferritic stainless steels. It offers a good balance of strength and corrosion resistance. Duplex stainless steel is commonly used in industries such as chemical processing, oil and gas, and marine applications.

Precipitation Hardening Stainless Steel Plates: a type of stainless steel plate that can be hardened through heat treatment. It offers high strength and excellent corrosion resistance. Precipitation-hardening stainless steel is often used in aerospace, nuclear, and chemical industries.

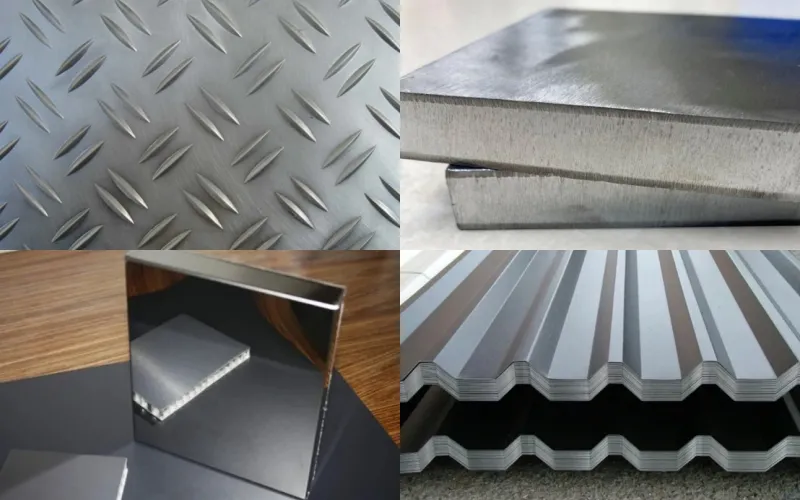

Surface

Mirror Stainless Steel Plates: made by using abrasive slurry to polish the plain stainless steel plate surface through polishing equipment to make the surface brightness as clear as a mirror. They are mainly used in building decoration, elevator decoration, industrial decoration, facility decoration, and other decorative applications.

Patterned Stainless Steel Plates: forming concave and convex patterns on the surface of plain stainless steel plates, which are often used in applications where smoothness and ornamental qualities are required.

Clad Stainless Steel Plates: a composite steel plate composed of a carbon steel plate base layer and a stainless steel plate cladding layer. It has a strong metallurgical bond between carbon steel and stainless steel, which can be hot pressed, cold bent, cut, welded, and other processing. Stainless steel clad plates are more applied in petroleum, chemical, salt industry, food processing, and other industries.

Corrugated Stainless Steel Plates: also known as stainless steel profiled plates, are metal sheets that are rolled and cold-bent into various corrugated profiles on stainless steel plates. These plates find applications in various industries, including wall cladding, roofing, oil and gas storage tanks, architectural applications, piping and ducting, filtration, and more.

Manufacturing Process

Hot rolled Stainless Steel Plates: produced through the hot rolling process.

Cold rolled Stainless Steel Plates: produced through the cold rolling process.

For more details, you can see our blog: Difference Between Hot Rolled Stainless Steel Plate and Cold Rolled Stainless Steel Plate

Performance

According to the performance, it can be divided into:

nitric acid-resistant stainless steel plates, sulfuric acid-resistant stainless steel plates, pitting-resistant stainless steel plates, stress-corrosion-resistant stainless steel plates, high-strength stainless steel plates

Function

According to the functional characteristics of stainless steel plates, they can be can be divided into:

low-temperature stainless steel plates, non-magnetic stainless steel plates, easy-cut stainless steel plates, super-plastic stainless steel plates

Buy Stainless Steel Plates from Stainless Steel Fabricator

Gnee Steel is one of the leading Stainless Steel Plate Manufacturers in China. SS Plates in our factory come in various materials, forms, sizes, standards, and finishes. With the specific services of quick delivery and precise engineering, we specialize in giving the best SS Plates at the most competitive costs. To inquire about our ss plate products, please feel free to request a quote.