Differences Between Hot Rolling and Cold Rolling

1. Definition

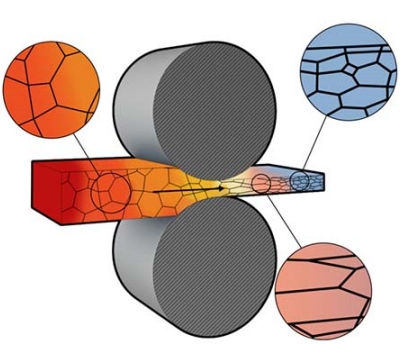

Hot rolling is a process that occurs at high temperatures above the recrystallization temperature of the material (usually 1700° F or greater).

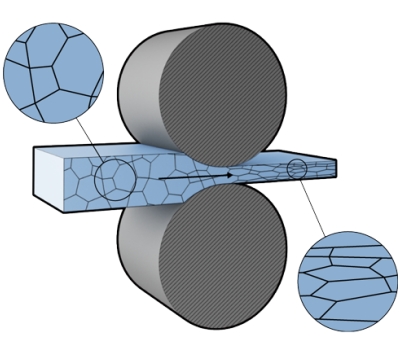

Cold rolling is a process that occurs at low temperatures below the recrystallization temperature of the material.

Therefore, “hot rolling” refers to processing done with heat. “Cold rolling” refers to processes done at or near room temperature. Although these techniques affect overall performance and application, they should not be confused with formal specifications and grades of steel, which relate to metallurgical composition and performance ratings. Steels of different grades and specifications can be either hot rolled or cold rolled—including both basic carbon steels, stainless steels, and other alloy steels.

2. Raw Material

Hot rolling mainly uses steel billets as raw materials, while cold rolling takes the hot rolled steel as substrates.

3. Manufacturing Process

The main difference between hot and cold rolling is in how they are manufactured.

The hot rolling process begins with a large, rectangular slab of metal referred to as a billet. Firstly, the billet is heated and compressed into a large roll. While still hot, it passes through a series of rotating rollers to achieve the desired dimensions. In steel coil production operations, the rolled steel is then wound into coiled rolls and left to cool. In production operations involving other forms, the processed material is cut into the specified shapes and packaged. The production process is:

Billet — annealing — heating — hot rolling — hot rolled steel

However, the cold rolling process is essentially hot rolled steel that has been further processed in cold reduction materials to improve its dimensional and mechanical properties. Here, the material is cooled followed by annealing and tempers rolling. The production process is:

Hot rolled steel — pickling — annealing — cold rolling — cold rolled steel

In a word, based on this, hot rolling is generally used to process ingots and billets; while cold rolling is generally used to produce coils and strips.

4. Production Capacity

When the metal is heated at a high temperature, the raw material’s deformation resistance decreases, but the thermoplasticity increases. This process increases the production rate as the machinery and motor get less worn out due to the malleability of the metal at that given point. Therefore, hot rolling usually has a faster production than cold rolling.

Correspondingly, hot rolling is more used to create large-scale products, while cold rolling is applied to create smaller-scale products.

5. Processing Performance

As the hot rolling process occurs at high temperatures, the processed material is more malleable and able to be turned into various shapes. At this point, it can be formed and reshaped easily. Cold rolled steel is processed at room conditions, making it robust and difficult to machine.

6. Mechanical Property

Statistics show that cold rolled steel can exhibit strength and hardness up to 20% greater than that of hot rolled steel counterpart. In the following table, a comparison of common mechanical properties for hot rolled and cold rolled steel is provided to get a feel of the mechanical property changes.

| Mechanical Properties | Hot Rolled | Cold Rolled | % change |

| Tensile Strength | 67,000 psi | 85,000 psi | 26.9 |

| Yield Strength | 45,000 psi | 70,000 psi | 55.6 |

| Reduction of Area | 58 | 55 | 52 |

| Elongation in 2” | 36 | 28 | 22.2 |

| Brinell Hardness | 137 | 167 | 18.0 |

7. Surface Quality

The surface of hot rolling steel is characterized by:

A scaly, rough, and non-oily surface texture — cooling from extreme temperatures leaves remnants on the steel surface.

Slightly rounded corners and edges — due to shrinkage and less precise finishing.

Silver-grey color.

Besides, where surface finish is a concern, the scaling of hot rolled steel can be removed by grinding, sandblasting, or acid-bath pickling. It can also offer a better surface for painting and other surface coatings.

On the contrary, the surface of cold rolling steel comes with:

A very smooth, shiny, and oily surface — since it does not involve using very high temperatures.

Sharp and tidy edges — due to fine processing at room temperature.

Silver-white color.

8. Internal Stress

Steel strength and hardness significantly impart internal stresses on the material. Therefore, cold rolled steel with greater strength and hardness has greater internal stresses than hot rolled steel. It is crucial to relieve such stresses before processing the material to prevent the warping of the final steel products.

9. Steel Section

Due to their different residual internal stress, the steel section of hot-rolled steel and cold-rolled steel is also very different. The steel section on the cold-formed steel is curved, while the steel section on the hot-rolled steel is non-curved.

10. Size

All cold rolled products provide higher precision and are superior in tolerance, concentricity, and straightness when compared to hot rolled products. Generally, cold-rolled thickness difference does not exceed 0.01 to 0.03mm. Take the stainless steel plate as an example:

| Products | Thickness |

| Hot rolled stainless steel plate | 3-20 mm |

| Cold rolled stainless steel plate | 0.5-5 mm |

11. Distortion

Hot rolled steel experiences slight distortions (e.g. through sheet metal bending) because the cooling process gives slightly trapezoidal shapes and forms. Cold rolled steel has perfectly squared angles with well-defined corners and edges.

12. Ductility

Hot-rolled steel is also more ductile than hot-rolled steel due to high-temperature processing. In other words, it can bend under greater stress without breaking. Hence, manufacturers can work with it more easily, manipulating the metal’s shape to fit their needs.

13. Cost

Hot rolled steel tends to be cheaper than cold rolled steel because it is manufactured without any delays in the process and does not require reheating like cold rolled steel. While the cold rolling process can be more labor-intensive and complex.

14. Application

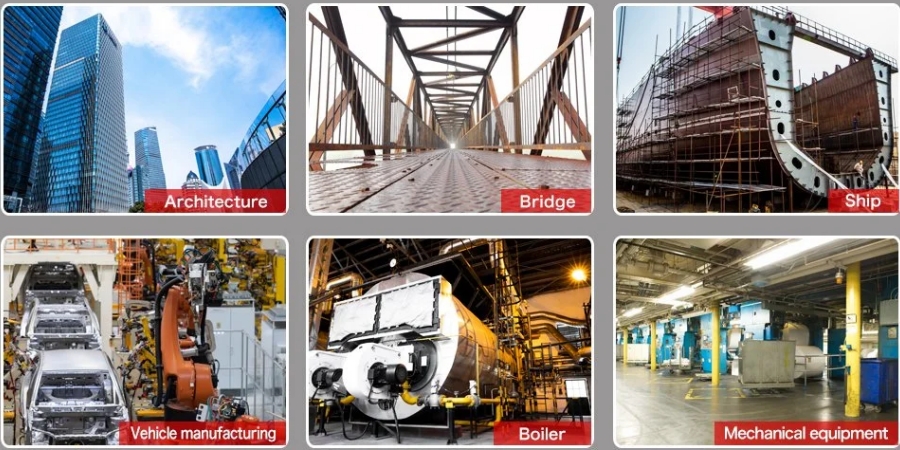

Hot rolled steel products are commonly used when precise shapes and tolerances are not essential, such as:

Construction: steel structure, beams, shipbuilding, etc.

Automobiles: automotive frames, wheel rims, tracks and railcar components, exhaust pipe, etc.

Machinery: agricultural equipment, stampings, mechanical components, etc.

Manufacturing: billets, sheets, slabs, tubes, bars, plates, pipes, rods, angles, substrate of cold rolled steel, etc.

By comparison, cold rolled steel is used in applications where tolerances, surface conditions, concentricity, and straightness are the major factors. Also, it is better suited for high-stress applications. Typical applications include:

Home appliances,

Metal furniture,

Aerospace structural components,

Precision instruments,

Food cans,

Doors and shelving,

Fan blades,

Frying pans,

Sheets, bars, rods, strips, pipes, coils, etc.

Cold Rolled Vs Hot Rolled Steel, Which One Suits My Projects?

The question of which process is better is a question that does not have a specific answer. As we discussed, the hot rolling and cold rolling process both have their benefits and drawbacks that make the ideal option change from project to project. To obtain the answer of which process is better, you need to know what you intend to manufacture in the first place. Then, whichever product suits your needs, Gnee Metal Supply is here to help.

Contact Gnee for Your Hot Rolled and Cold Rolled Stainless Steel

Gnee is an industry-leading supplier of premium hot-rolled and cold-rolled stainless steel products. We offer plentiful stainless steel — including sheets, plates, bars, rods, coils, pipes, foils, and pipe fitting products. And the purchase options include next-day delivery and will-call pickup options. Whether you’re located in China or not, we can provide the hot-rolled and cold-rolled stainless steel products your project requires. Just select your desired metal, shape, dimensions, and grades now!