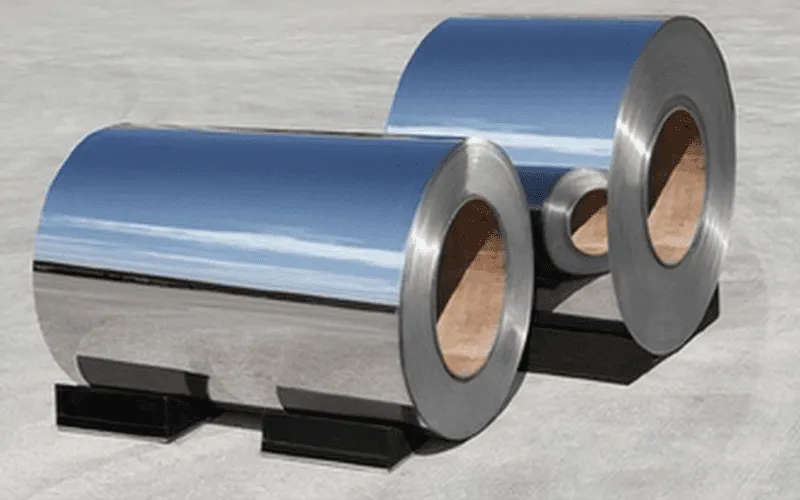

400 Series Stainless Steel Coil

Before getting to know 430 stainless steel coils, let us first understand its brothers and sisters: 409, 410, and 410 stainless steel coils, they all belong to 400 series stainless steel coils.

400 series stainless steel coils are stainless steel coils composed of iron, chromium, nickel, and other alloying elements. Manufactured by smelting, rolling, and annealing, it has excellent mechanical properties. The 400 series includes ferritic steel and martensitic steel. Compared with the 00 series stainless steel coil, the 400 series has increased chromium and manganese content, higher carbon content, higher wear resistance, and a wide range of applications.

Let’s take a look at the characteristics of 430, 409, 410, and 410 stainless steel coils!

1. 409 Stainless Steel Coil

- Usually contains elements such as iron, chromium, molybdenum, nickel, and manganese

- Low price, ferrite structure

- Often used in automotive exhaust systems, stoves, and heat exchangers

2. 410 Stainless Steel Coil

- Usually contains elements such as iron, chromium, and carbon

- Martensitic structure, high strength

- Often used in tools, bearings, valves, pumps, auto parts

3. 420 Stainless Steel Coil

- Usually contains elements such as iron, chromium, and carbon, with a high carbon content

- Martensitic structure, excellent polishability

- Often used in knives, surgical instruments, tableware, clocks, stone cutting tools

4. 430 Stainless Steel Coil

- Usually contains elements such as iron, chromium, and a small amount of nickel

- Ferrite structure, good formability

- Architectural decoration, kitchen utensils, automotive exteriors, electrical panels, accessories, etc.

Learn About 430 Stainless Steel Coil

430 stainless steel coil is a coiled product made of 430 stainless steel. It is an iron-chromium alloy stainless steel with a chromium content of 16%-18%, which is lower than the chromium content of 304 stainless steel and 316 stainless steel. Some are slightly inferior in terms of corrosion resistance and strength.

However, 430 stainless steel coils have the advantages of excellent heat resistance and magnetic properties, as well as more economical prices. In some occasions that require medium strength and corrosion resistance, such as household appliance manufacturing and other industries, it has been widely used, and it is an economical and practical stainless steel material.

Advantages of 430 Stainless Steel Coil

- Good heat resistance

- Has a certain degree of magnetism

- Good processing performance, easy to process into various shapes

- Low chromium content, poor corrosion resistance, but still has good corrosion resistance in a dry environment

Difference Between 430, 409, 410, and 420 Stainless Steel Coil

430 stainless steel coils, 409 stainless steel coils, 410 stainless steel coils, and 420 stainless steel coils are common types of stainless steel coils. Only by fully understanding their differences in chemical composition, mechanical properties, and application fields can we choose a suitable stainless steel coil to ensure that the material is For optimum performance and durability in specific environments.

| Type | Chemical Composition | Mechanical Behavior | Application Field |

| 430 Stainless Steel Coil | Usually contains about 16%-18% chromium and less than 0.12% carbon, and may contain small amounts of nickel, but the nickel content is low | It has low strength and hardness, good corrosion resistance, and magnetic properties. | Widely used in kitchen utensils, architectural decoration, home appliances, and automobile industry, and other fields. |

| 409 Stainless Steel Coil | It usually contains about 10%-11% chromium and relatively high iron content and also contains about 0.08% carbon and a small amount of titanium and aluminum. | It has high strength and low corrosion resistance. | Mainly used in high-temperature applications such as automotive exhaust systems, stoves, gas lines, and heat exchangers. |

| 410 Stainless Steel Coil | It is a high-carbon stainless steel containing about 11.5%-13.5% chromium and more than 0.15% carbon. | It has high hardness, strength, and wear resistance, but poor corrosion resistance. | Commonly used in applications requiring high hardness and wear resistance such as cutting tools, bearings, valves, and mechanical parts. |

| 420 Stainless Steel Coil | It is a high-carbon stainless steel containing about 12%-14% chromium and 0.15%-0.40% carbon. | Has high hardness and wear resistance. | Commonly used in applications requiring high hardness and wear resistance such as knives, surgical instruments, tools, and molds. |

Application Fields of 430 Stainless Steel Coil

Kitchen Utensils: It is widely used in the production of kitchen utensils, such as pots, tableware, and cooking utensils.

Architectural Decoration: It is often used to make decorative elements such as doors, windows, handrails, and guardrails. It is an ideal building material.

Automobile Industry: It is often used to make exhaust systems, exterior decorations, and parts.

Furniture Manufacturing: It is used to make furniture frames, chair legs, bed frames, etc.

430 Stainless Steel Coil Care and Maintenance

To maintain the appearance and performance of 430 stainless steel coils and prolong the service life of 430 stainless steel coils, we have some maintenance and maintenance suggestions for you:

Cleaning Method: Use a mild detergent and a soft cloth to clean the surface of the 430 stainless steel coil, and avoid using cleaning tools with large abrasive grains to avoid scratching the surface.

Protective Measures: Avoid prolonged contact with salt, acidic and alkaline substances to prevent corrosion. Special coatings or protective films can be considered to increase the corrosion resistance of 430 stainless steel coils.

With proper maintenance and care, 430 stainless steel coils can prolong their life and maintain their good looks and performance.

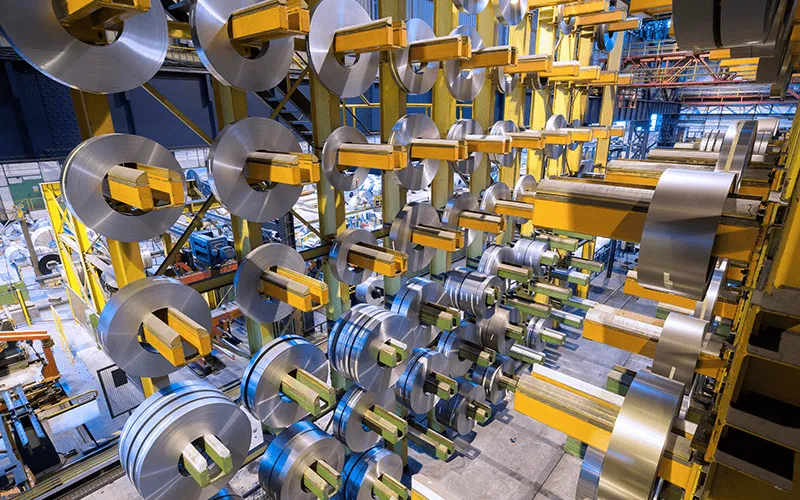

430 Stainless Steel Coils Factory

The Gnee Steel Group is a professional supply chain enterprise, mainly engaged in steel plate, coil, profile, and outdoor landscape design and processing. After 15 years of development, it has become a leading international steel supply chain company in the Central Plains. Relying on many iron and steel enterprises such as Angang Steel, we have a wide variety of products, including shipbuilding plates, pressure vessel plates, bridge decks, etc. We also provide pipes, bars, engineering design and manufacturing, and comprehensive stainless steel solution services. Cooperating with more than 600 companies around the world, the annual export capacity exceeds 80,000 metric tons. Choose Gnee Steel Group, you choose a professional and reliable steel supply chain partner!