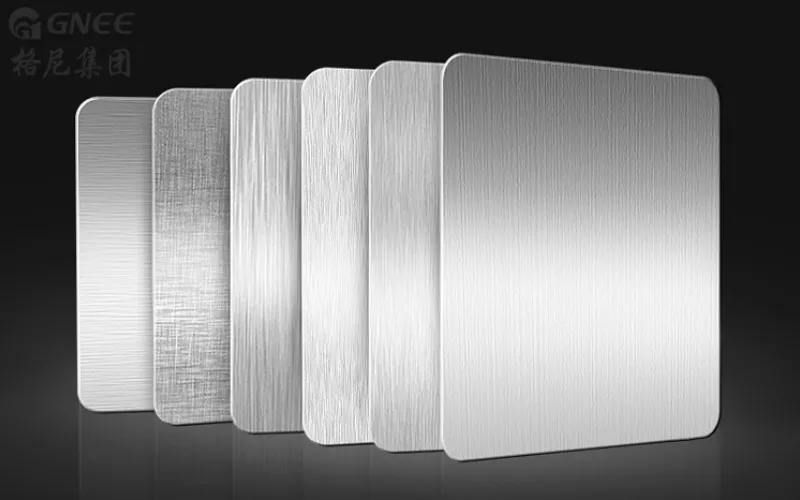

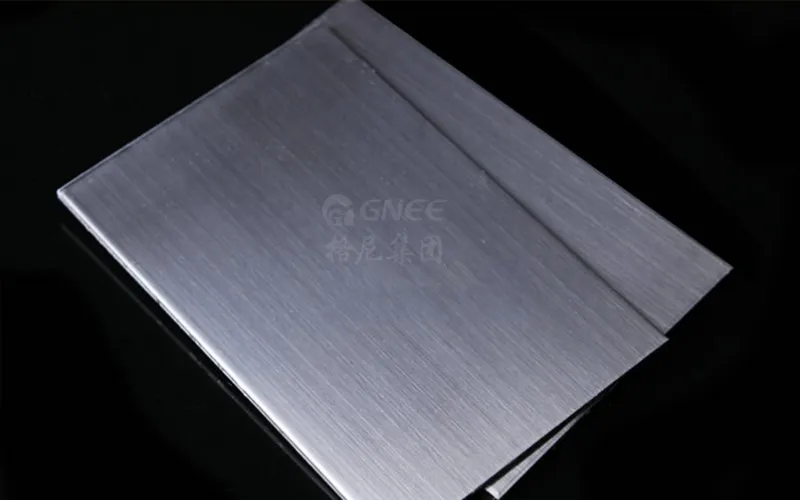

What Is Brushed Stainless Steel Plate?

A brushed stainless steel plate is a regular stainless steel sheet/plate that has been treated through brushing techniques to create a unique texture or finish characterized by fine parallel lines commonly known as “grain”. The brushing process involves either mechanical abrasion or hand drawing methods and results in a surface that looks like metal wool or sandpaper was used on it. Therefore, it is much duller than traditional polished stainless steel finishes and helps to hide fingerprints, scratches, and other imperfections. Brushed stainless steel products are widely used in kitchen appliances, architectural designs, furniture, fashion, and decorative applications.

Here you can see the whole production process of brushed stainless steel plate in the following steps:

1. Purchasing raw materials: stainless steel coils.

2. Uncoiling the stainless steel coils and slitting them into strips.

3. Shearing the strips into desired sizes.

4. Pressing the sheets into shape.

5. Brushing by hand or machine.

6. Inspecting and packaging the finished product.

Pros and Cons of Brushed Stainless Steel Plates

When it comes to brushed stainless steel plates, there are both advantages and disadvantages to using this type. Next, let Gnee Steel walk you through these features in detail.

Pros You Can Enjoy from Brushed Stainless Steel Material

1. Sleek Appearance

The wire drawing process uses abrasive materials to perform back-and-forth mechanical movement and chemical corrosion on the surface of the metal plate so that the surface of the workpiece obtains a layer of linear texture with uniform thickness distribution. This gives the brushed stainless steel plates a unique and captivating visual appeal that sets them apart from other finishes. It not only largely reduces reflectivity but also adds a touch of sophistication to any space due to its modern look, making the plate a popular choice for those seeking to elevate their interior design.

2. Strong Abrasion Resistance

Under normal circumstances, brushed stainless steel plate is more resistant to wear and tear than bright stainless steel plate and looks more upscale.

3. Great Durability

Brushed stainless steel plates exhibit impressive mechanical properties that contribute to their overall durability. With high impact resistance capabilities, they can withstand accidental knocks or heavy use without compromising their structural integrity. Furthermore, the wire drawing process itself enhances the scratch resistance of the surface. The textured grain pattern effectively conceals minor scratches or scuffs that may occur over time due to everyday usage.

4. Easy Cleaning

Compared with mirror stainless steel (No.8 finish), brushed stainless steel surface is usually polished with much less smoothness and gloss. It can visually conceal the dirt, dust, fingerprints, and sweat stains on its surface. Plus the non-porous nature, the brushed stainless steel helps save you much effort and time for cleaning and maintaining.

5. Various Designs

Different brushing methods will produce different linear textures so that the brushed stainless steel has different linear texture shapes. Generally, wire drawing textures can be divided into straight grains, random grains, ripples, swirl grains, etc. Now let’s keep discovering these four main patterns that brushed stainless steel sheet comes in.

| Patterns | Definition |

| Straight Grain

|

It is also known as the hairline finish, usually processed by mechanical friction on the stainless steel plate to obtain a long, unidirectional, and straight linear texture on the surface parallel to the longitudinal metal panel. It usually contains long linear texture and short linear texture. In addition, the linear textures of different thicknesses can be obtained by changing the diameter of the steel brush.

|

| Random Grain | Seen from a distance, the brush’s stainless steel surface is composed of circles of sand patterns, while up close, there are random irregular grains. This is because it is ground by the irregular swing of the grinding head up, down, left, and right. The production of this kind of texture is very demanding, and the surface is matte.

|

| Ripple | Its production process uses the axial movement of the upper set of grinding rollers on a brushing machine or a graining machine so that the stainless steel surface obtains a wavy pattern after being brushed. |

| Swirl Grain | The production process is: 1) use a small motor with a round felt on its shaft. 2) Fix the small motor on the table at an angle of about 60° to the edge of the table. 3) put a carriage to fix the stainless steel plate, and a piece of polyester film is also attached to the edge of the carriage to limit the thread speed. 4) rotating the felt and mop in a straight line so that the stainless steel plate can obtain the thread patterns of the same width on its surface. |

Moreover, it can add some color by chemical water plating or vacuum ion plating on the surface of the base material of the stainless steel wire drawing plate. It is called colored stainless steel brushed plate. And coatings can also be applied, such as electroplating and galvanizing coatings.

6. Wide Versatility

These dense linear grains on the surface look beautiful and provide a milder tone, which can effectively hide scratches, fingerprints, and other blemishes. This makes it ideal for appliances such as kitchenware, architectural designs, furniture, all kinds of equipment enclosures, various door panels/guards, logos, elevators, etc. It is also suitable for not requiring a highly reflective effect to brighten the space.

Cons You Need to Know When Using Brushed Stainless Steel

However, there are some drawbacks to using brushed stainless steel plates as well. You need to know what they are before deciding whether to buy.

1. High Cost

One of the biggest is that it can be quite more expensive than non-brushed stainless steel. Of course, which one is better, brushed or non-brushed stainless steel plate, depends on the customer’s actual needs. If you need the advantages of brushed stainless steel but can accept the disadvantages of brushed stainless steel (the unit price is slightly higher), Gnee recommends using brushed stainless steel plates.

2. Low Corrosion Resistance

Another big disadvantage is its low corrosion resistance. The corrosion resistance of brushed stainless steel plates will be worse than that of non-brushed ones because the wire drawing process will destroy the composition and chromium content of the stainless steel plate surface. As we all know the anti-corrosion performance of stainless steel plate mainly depends on the chromium content. If the chromium is damaged, its corrosion resistance is reduced accordingly. Therefore, when purchasing stainless steel plates, it is necessary to consider the environment and use purpose to determine whether to draw wires.

3. Thickness Loss

Generally speaking, the wire drawing process will lose the thickness of the stainless steel plate to a certain extent, generally 0.1~0.2mm.

4. Periodic Cleaning

The human body, especially the palms, has a relatively strong secretion of oil and sweat, which will leave obvious fingerprints on brushed stainless steel plate surfaces if frequently touched by hand. Therefore, they need to be scrubbed regularly to maintain their pristine appearance. Here are some maintenance tips for brushed stainless steel products to keep in mind:

-Regularly dust your brushed stainless steel products with a soft, dry cloth. This will help prevent dirt and grime from building up on the surface.

-If you need to clean your brushed stainless steel, use a mild soap and water solution. Avoid harsh cleaners or abrasive pads, as these can damage the finish.

-To remove fingerprints or smudges, use a lint-free cloth dampened with distilled water. You can also use a gentle glass cleaner on occasion.

-Be careful when using metal polish or waxes on brushed stainless steel. These products can dull the finish over time. If you use them, apply sparingly and immediately buff off any excess.

Contact Brush Stainless Steel Supplier for More Details

In conclusion, brushed stainless steel plate has emerged as a versatile material that not only enhances the visual appeal of stainless steel plate but also brings forth a touch of sophistication to various surfaces. It has found its place in both home appliances and architectural building and fashion designs. Check out the advantages and disadvantages of brushed finish stainless steel mentioned above to learn more. If you have the desire to buy, feel free to contact us today to get a quote here.