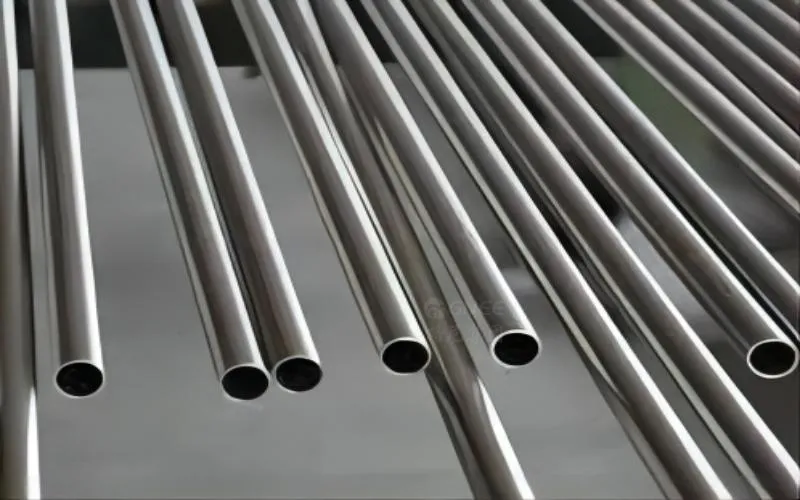

What is a stainless steel sanitary pipe?

A type of long steel with a hollow cross-section and no seams all the way around is known as a stainless steel sanitary tube. The product’s wall thickness influences how economical and practical it is; if the wall thickness is too thin, processing expenses will significantly increase. The product’s procedure also determines its limitations. Performance, general seamless steel pipe precision is low: wall thickness is not uniform, the tube’s interior brightness is low, sizing costs are high, and the interior appearance pockmarks and black dots are difficult to remove; they must be detected and shaped offline. The most prevalent stainless steel pipe variants are 304 or 316L.

What is the standard of sanitary stainless steel pipe?

Sanitary stainless steel tube is primarily used in production equipment and assembly lines for the food, beverage, alcohol, bioengineering, and other industries. As a result, there are specific requirements for the surface finish, oil ban, and passivation layer of stainless steel tubes. First and foremost, we must confirm that the pipe complies fully with the national standards for “Thin-walled Stainless Steel Water Pipes” and “Safety Evaluation Standards for Living Drinking Water Transmission and Distribution Equipment” (GB/T151-2001) and is hygienic, non-toxic, and non-polluting.

1. Surface finish: The tube’s interior and external surfaces have been polished, resulting in a dazzling surface that is frequently referred to as a mirror. The major goal of this is to stop fluids from flowing back and forth inside the tube and create a hanging wall, which can quickly get contaminated and clog the pipes.

2. Passivation layer: To give steel pipes their corrosion-resistant properties, they must be immersed in a passivation pool after polishing is complete. The acidic passivation solution will oxidize to form a passivation layer on the steel pipes’ surface.

3. Oil ban: To get rid of the oil on the steel pipe’s surface after passivation, oil ban cleaning is done. Following completion of the inspection, a grease analyzer is required to prevent oil from contaminating the tube’s wall and keep the fluid material away from it.

Advantages of Stainless Steel Sanitary Pipe

1 Does not cause dangerous metal precipitation to occur in persons

We know that the stainless steel sanitary pipe is the safest and most hygienic water pipe material, following health standards, and will not cause secondary pollution of water quality, to meet the national direct drinking water quality standards. This understanding extends to medical equipment and food tableware.

2 Won’t pollute the environment

Sanitary pipes made of stainless steel can be recycled, protecting future generations from having to deal with their waste.

3 Preserving water supplies

The strength of stainless steel sanitary pipe material is higher than any other water pipe materials, significantly lowering the likelihood of leakage of water pipes impacted by outside forces and resulting in significant water savings.

4 Great resistance to corrosion and abrasion

The stainless steel water pipe has excellent corrosion resistance in all water qualities, including soft water, and can endure high-speed water erosion up to 30 m/s. Its surface is thin and dense with a chromium-rich oxide film.

5 Minimise heat loss

The insulating effectiveness of stainless steel sanitary water pipes is 24 times that of copper sanitary water pipes, resulting in significant reductions in heat loss during the delivery of hot water.

Sanitary Stainless Steel Pipe Applications

Sanitary stainless steel pipe is made especially for uses requiring a high level of hygienic standards and corrosion resistance. It is frequently employed in sectors like food and beverage, pharmaceuticals, biotechnology, dairy, and cosmetics where it is crucial to maintain product purity and avoid contamination.

1. Food and beverage sector: Stainless steel sanitary tubing is frequently used for processes like fluid transfer, product delivery, and CIP (clean-in-place) systems in the food and beverage industry. Applications that deal with perishable foods, drinks, and delicate ingredients must have it.

2. The manufacturing of drugs and vaccines, aseptic processing, and cleanroom applications all need the usage of stainless steel sanitary tubes, which are essential in these industries. Stainless steel has a strong corrosion resistance, which guarantees product integrity and prevents contamination.

3. Dairy industry: Milk processing, cheese production, and other dairy industrial processes all need sanitary stainless steel tubing. To ensure hygienic delivery of milk and dairy products, it complies with strict hygiene regulations.

4. The production of lotions, creams, shampoos, and other personal care goods uses sanitary stainless steel tubes, which are also used in the manufacturing of other personal care items. It permits the safe and hygienic transportation of ingredients and guarantees the quality of the finished product.

5. Brewing and beverage industry: Breweries and beverage production facilities employ stainless steel sanitary tubing for the transport of beer, wine, spirits, and other beverages. It keeps products pure and avoids contamination while they are being produced.

6. Sanitary stainless steel pipe is used in the water treatment industry for the provision of drinking water and the treatment of wastewater in water treatment plants. It guarantees a sterile water supply, stops bacterial growth, and preserves water quality.