Meet 409 stainless steel coil

409 stainless steel coil is a special stainless steel material composed of iron, chromium, titanium, and other elements, which has excellent corrosion resistance, good mechanical properties, and formability.

It is made through the steps of smelting, casting, hot rolling, cold rolling, annealing, and pickling. It is widely used in many fields such as automobile manufacturing, petrochemical industry, and environmental protection facilities. It is a comprehensive and cost-effective stainless steel product.

Composition of Stainless Steel 409 Coils

409 stainless steel coil is a ferritic stainless steel mainly composed of iron (Fe) and the following elements:

- Carbon (C): The maximum allowable content is 0.08%.

- Silicon (Si): The maximum allowable content is 1.00%.

- Manganese (Mn): The maximum allowable content is 1.00%.

- Phosphorus (P): The maximum allowable content is 0.045%.

- Sulfur (S): The maximum allowable content is 0.03%.

- Chromium (Cr): The maximum allowable content is 10.50% – 11.75%.

- Nickel (Ni): The maximum allowable content is 0.50%.

- Molybdenum (Mo): The maximum allowable content is 0.50%.

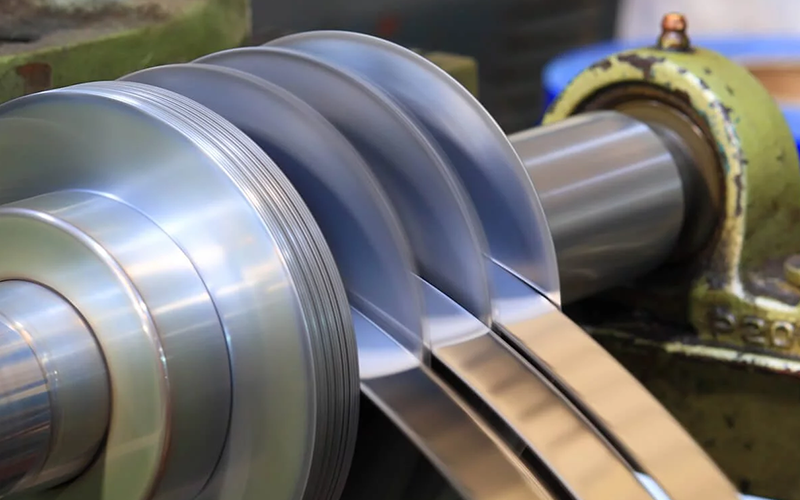

How to Make Stainless Steel Sheets into Stainless Steel Coils

1. Material preparation

Select appropriate stainless steel plates as raw materials. Commonly used stainless steel grades include 304, 316, 409, 430, etc.

2. Hot rolling or cold rolling

The stainless steel sheet is fed into a rolling mill for hot or cold rolling. Hot rolling is carried out at high temperatures, and the sheet is pressed through multiple rolls to the required thickness and width. Cold rolling is carried out at room temperature, and the sheet is gradually thinned by rolling to obtain the required size.

3. Pickling and surface treatment

There may be oxides, grease, or other impurities on the surface of the rolled stainless steel plate. Pickling and surface treatment are required to remove these impurities and make the surface smoother.

4. Cutting

According to the need, cut the stainless steel plate into the required length and width.

Coiling: The cut stainless steel plate is rolled into a roll by a coiling device.

5. Packaging and Storage

Stainless steel coils are packaged for shipping and storage. Common packaging methods include wrapping with plastic film or using wooden boxes. Our company usually uses wooden boxes for packaging and shipping by sea.

Features of 409 Stainless Steel Coil

Good corrosion resistance:409 stainless steel coil contains high chromium content, which has excellent corrosion resistance and can resist the erosion of most corrosive media.

Good mechanical properties:Under high-temperature and low-temperature conditions, 409 stainless steel coils maintain good mechanical properties, have high yield strength and tensile strength, and have good application potential in structural parts and load-bearing components.

Magnetic:409 stainless steel belongs to ferritic stainless steel, which has certain magnetic properties, which makes it have certain advantages in some specific application scenarios (such as electromagnetic applications).

Formability:409 stainless steel can be easily formed and rolled into various shapes, making it a popular choice for applications that require forming or bending.

High-cost performance:Compared with other types of 400 series stainless steel coils, the cost of using 409 stainless steel coils is relatively low, which is a more economical and practical choice.

Recyclability:Stainless steel (including 304, 316, 410, 430, etc.) is a highly recyclable material. At the end of its useful life, the stainless steel coil can be recycled and reused, contributing to sustainability and environmental protection.

What is the difference between a 409 stainless steel coil and a 410 stainless steel coil?

The names of 409 stainless steel coil and 410 stainless steel coil sound so similar, some people will ask if they are the same. Of course, 409 and 410 stainless steel coils are two different stainless steel materials, and they have some differences in chemical composition, mechanical properties, and applications:

Chemical composition:The chemical composition of the 409 stainless steel coil and 410 stainless steel coil is different. 409 stainless steel coils generally contain higher chromium (Cr) and lower carbon (C) content, while 410 stainless steel coils generally contain higher carbon and chromium content.

Mechanical properties:409 stainless steel coils generally have higher tensile strength and lower yield strength, while 410 stainless steel coils will have slightly stronger yield strength.

Corrosion resistance:409 stainless steel coil has good corrosion resistance, especially in an environment containing chloride and acid. The corrosion resistance of 410 stainless steel coil is better in the oxidizing medium.

Application fields:409 stainless steel coils are mainly used in automobile exhaust systems, combustion chambers and chimney pipes, home appliance manufacturing, and other fields. 410 stainless steel coils are often used in the manufacture of knives, valves, bearings, and other applications that require higher hardness and wear resistance.

What are the application scenarios for 409 stainless steel coils?

Due to its strong corrosion resistance, good mechanical properties, formability, and low cost, 409 stainless steel coils are widely used in automobile manufacturing, mufflers, catalytic converters, building decoration materials, municipal environmental sanitation, public facilities, Widely used in kitchen equipment, and other fields.

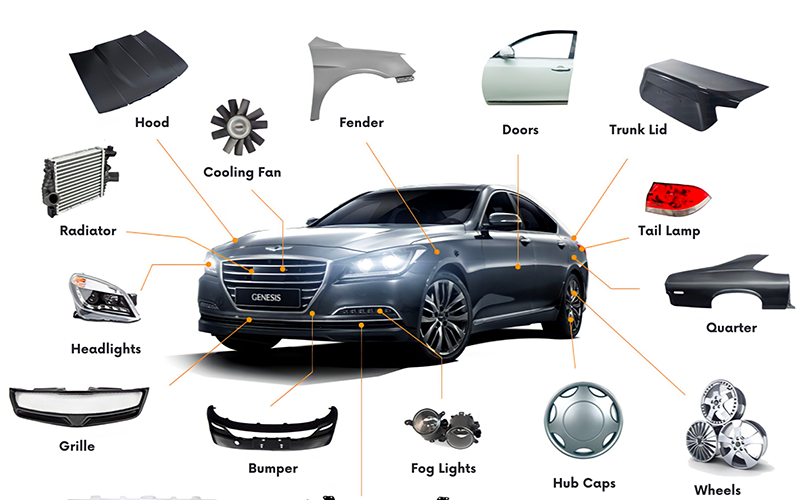

Automobile industry

409 stainless steel coil has high-temperature resistance, corrosion resistance, and good welding performance, which can meet the requirements of automobile emission and prolong the life of parts. It is often used in the manufacture of automobile exhaust systems, such as exhaust pipes, mufflers, and exhaust systems.

Petrochemical

409 stainless steel coils have excellent corrosion resistance and can maintain stability in complex chemical medium environments. They are widely used in petrochemical equipment, such as petroleum storage tanks, chemical containers, and pipelines.

Environmental protection facilities

409 stainless steel coils are high temperature resistant, cost-effective, and can maintain long-term stable operation in harsh environments. They are often used in environmental protection facilities, such as garbage incinerators and waste gas treatment devices.

Agricultural equipment

409 stainless steel coils have excellent corrosion resistance and can resist the erosion of moisture and chemicals in agricultural environments. In the field of agriculture, it is used to manufacture agricultural machinery and equipment, such as greenhouse skeletons for orchards and vegetable cultivation, agricultural vehicles, etc.

409 stainless steel coils are widely used in many industries such as automobiles, petrochemicals, construction, and environmental protection facilities. Its excellent performance makes it a stainless steel material with comprehensive functions and a wide range of applications. If you are interested in 409 stainless steel coils or other stainless steel products such as 2205, 2507 stainless steel coils, etc., please feel free to contact us!

Two important factors cannot be ignored when manufacturing Stainless Steel 409 Coils:

- Application environment;

- The strength of the material itself;

Stainless Steel 409 Coils Manufacturer

The Gnee Steel Group is a professional supply chain enterprise, mainly engaged in steel plate, coil, profile, and outdoor landscape design and processing. After 15 years of development, it has become a leading international steel supply chain company in the Central Plains. Relying on many iron and steel enterprises such as Angang Steel, we have a wide variety of products, including shipbuilding plates, pressure vessel plates, bridge decks, etc. We also provide pipes, bars, engineering design and manufacturing, and comprehensive stainless steel solution services. Cooperating with more than 600 companies around the world, the annual export capacity exceeds 80,000 metric tons. Choose Gnee Steel Group, you choose a professional and reliable steel supply chain partner!

What can we do for your Stainless Steel 409 Coils project?

- Whether you’re a dealer or a fabricator, choosing a high-quality 409 stainless steel coil can help you bring lasting value to every project.

- The Gnee team can provide reliable, safe, and economical stainless steel solutions for the precise needs of each end user.

- We will help you with all your stainless steel strapping needs.

- Welcome to contact us for more stainless steel cases and solutions.