An Overview of 304 Stainless Steel Sheet and Plate

304 Stainless steel plate is known as one of the most versatile stainless steels available in the market. It is usually made up of austenitic stainless steel that has 18–20% chromium and 8–10.5% nickel, along with other small amounts of carbon, silicon, manganese, phosphorus, and sulfur in the composition. In this regard, it is also known as an 18/8 stainless steel plate in the industry.

Besides, 304L is the low-carbon version of 304.

Grade 304 Stainless Steel Chemical Composition

| C | Si | Mn | Cr | Ni | S | P |

| ≤0.08 | ≤1.0 | ≤2.0 | 18.0~20.0 | 8.0~10.5 | ≤0.03 | ≤0.035 N≤0.1 |

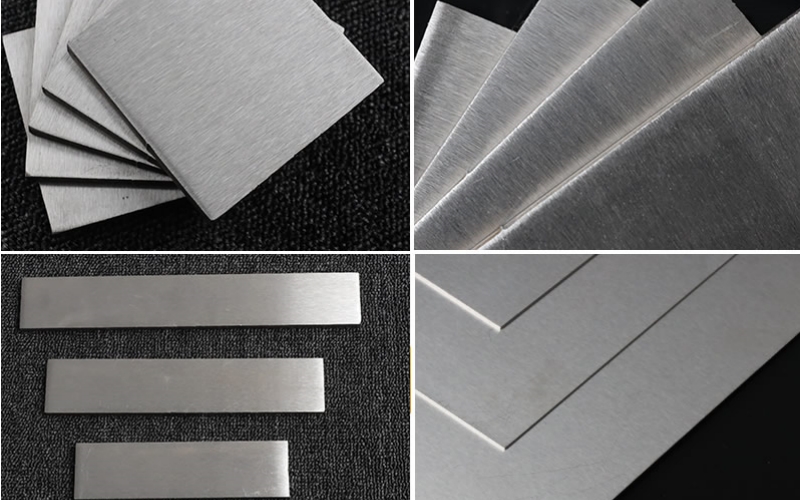

Marking Method of 304 Stainless Steel Sheet and Plate

The common marking methods of 304 stainless steel are 06Cr19Ni10, ASTM 304, and SUS304, in which 06Cr19Ni10 generally refers to production under national standards, ASTM 304 refers to production under American standards, and SUS 304 refers to production under Japanese standards. As for others, STS304 refers to the Korean standard, 1.4301 represents the European standard, and 304 reveals the Australian standard.

Production of 304 Stainless Steel Sheet and Plate

Generally speaking, 304 stainless steel plate is made by rolling technique on 304 stainless steel coils. Rolling can be divided into hot rolling and cold rolling. Hot rolling is manufactured at high temperatures while cold rolling is fabricated on hot-rolled 34 stainless steel plates at room temperature.

Advantages of 304 Stainless Steel Sheet and Plate

1. Superior Corrosion Resistance

When compared with standard carbon steel and low alloy steel, industrial 304 stainless plate provides enhanced protection against corrosion, rust, staining, and other corrosive media (like water, oil, acids, salts, etc). This mainly depends on its alloy composition and internal structure, and the main role is chromium. Chromium has high chemical stability and can form a passivation film on the steel surface to isolate the metal from the outside world, protect the steel plate from oxidation, and increase the corrosion resistance of the steel plate. If the passivation film is destroyed, its corrosion resistance will sharply decrease.

2. Excellent Formability

304 Stainless steel plate has good formability and can be simple to manufacture and shape by all common methods. During the manufacturing process, products of various shapes and sizes can be manufactured by cutting, bending, welding, shearing, sawing, etc.

What’s more, it should be noticed that 304 is subject to work hardening during deformation and is subject to chip breaking. The best machining results are achieved with slower speeds, heavier feeds, excellent lubrication, sharp tooling, and powerful rigid equipment.

3. High Toughness

304 stainless steel plate has excellent mechanical properties, its strength and plasticity are higher than ordinary steel. It can withstand the stress of high temperature, high pressure, and heavy load without deforming or cracking. In addition, its mechanical properties can be changed by cold working or heat treatment, so that it can meet various application requirements.

4. Heat Resistance

304 stainless steel plate also has good resistance to heat, oxidation, and wear in intermittent service up to 870°C and in continuous service to 925°C. However, continuous use at 425-860°C is not recommended if corrosion resistance in water is required.

Additionally, it is non-magnetic and has low thermal conductivity, which can retain heat longer than other metals when heated.

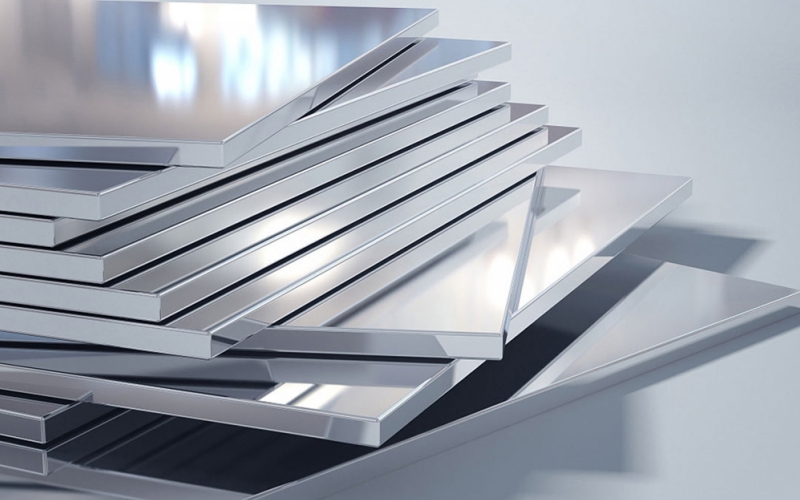

5. Elegant Finish

From the naked eye, it has a flat, glossy, and smooth surface, providing a very sleek modern feel. This can add a sense of luxury to your building constructions.

6. Easy Maintenance

Due to its non-porous surface and smooth metal texture, the 304 stainless steel plate is easy to clean and maintain.

Common Applications for 304 Stainless Steel Sheet and Plate

As a cost-effective and versatile steel material, 304 stainless steel sheet and plate is frequently used in construction, automobiles, machinery, aerospace, electricity, manufacturing, pharmaceutical/medical/chemical processing, and other industries. Some typical examples are listed below:

Construction: architecture and building construction, roofing, paneling, steel structures, shipbuilding, etc.

Manufacturing: it can be used to fabricate 304 stainless steel welded pipes, 304 stainless steel profiles, and 304 stainless steel pipe fittings. Also, this plate can be used to produce nuts, bolts, screws, and other fasteners.

Automotive industry: exhaust systems, automotive trim, car body, engine, wheel covers, etc.

Machinery: medical equipment and instruments, petroleum refining equipment, pulp and paper making equipment, marine equipment, and other industrial equipment.

Home appliances: benches, chairs, furniture, refrigerator, air-conditioner, electrical enclosures, kitchenware, etc.

Public uses: decoration, beverage and food handling, heat exchangers, piping systems, storage tanks, pressure vessels, conveyors, containers, flanges, valves and pumps, hardware tools, grills, etc.

Is 304 Stainless Steel Food-grade Stainless Steel?

The answer is: 304 stainless steel is “not equal to” food-grade stainless steel. By definition, food-grade stainless steel refers to the stainless steel material that meets the national GB 4806.9-2016 standard certification and can come into contact with food without causing physical harm. Therefore, only “specially treated 304 stainless steel (meet the heavy metal precipitation standard)” is food-grade stainless steel, while ordinary 304 stainless steel is not food-grade stainless steel.

Is 304 Stainless Steel Products Rustproof?

While 304 stainless steel may be more resistant to corrosion and rust than other metals, it still can rust if exposed to certain environmental conditions such as high humidity, salt water, or a poor circulation environment. This corrosion appears in the form of brown spots or streaks on the surface of the metal and can eventually lead to pitting or rusting if not treated properly.

How Can I Prevent 304 Stainless Steel from Rusting?

Fortunately, there are some steps that we can take to prevent the 304 stainless steel plate from rusting or corroding. One way to do this is by cleaning the stainless steel regularly with warm water and soap. This will help to keep dirt and debris off the surface of the metal, which can cause staining or discoloration over time. Secondly, you should dry the stainless steel after each use, as moisture left behind can cause further damage. Finally, consider applying sealants or coatings on your stainless steel objects which will help protect the metal from exposure to moisture and other corrosive elements in its environment.

In a word, with proper care and maintenance, you can ensure that your 304 stainless steel products remain rust-free for years to come!

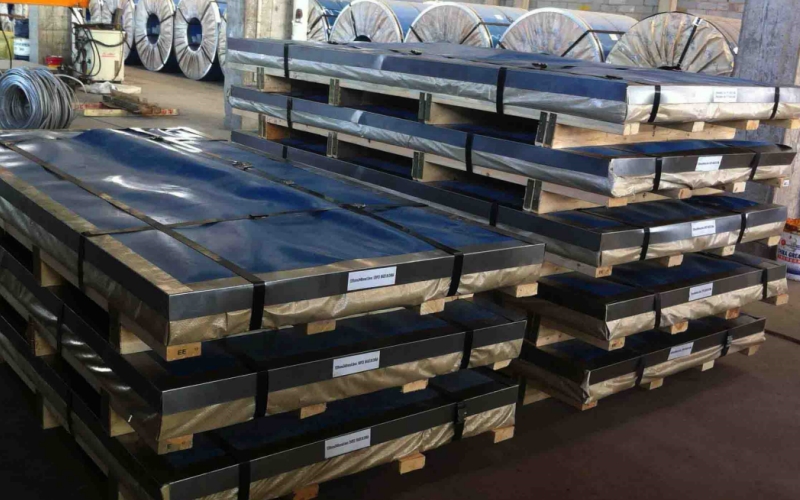

304 Stainless Steel Sheet and Plate Manufacturer in China

Manufacturers and end-users requiring reliable and durable materials must understand the properties, uses, production, and composition of 304 stainless steel sheets and plates. If you still have some confusion, come to contact us for a technical advisor’s help!

Gnee Steel is a value-added stainless steel distributor in China. Our stocks of stainless steel sheets and plates are available in 301, 304, 310, 316, and 430 grades in a choice of dull polished finish which has a smooth, clean, non-reflective surface. Besides, all our stainless steel sheet metal is supplied with a protective film on the finished side, which can easily be peeled off after installation or fabrication. If you are interested, come to contact us for further talking!