Introduction to Stainless Steel Square Pipes and The Unique Characteristics

Corrosion Resistance of Stainless Steel Square Pipes

Stainless steel square pipes are known for their excellent rust and corrosion resistance. Chromium is principally responsible for this extraordinary feature of stainless steel. When exposed to oxygen, a passive layer of chromium oxide forms on the surface of the steel, creating a protective barrier. Importantly, this corrosion resistance makes stainless steel square pipes highly suitable for applications where they are exposed to harsh environments or corrosive substances such as acids, alkalis, and salts.

In chemical processing plants and oil refineries, where pipelines come into contact with aggressive chemicals regularly, stainless steel square pipes offer long-lasting durability combined with excellent performance.

Strength and Durability of Stainless Steel Square Pipes

Stainless steel square pipe has excellent strength, high tensile strength, excellent mechanical properties, and durability. In comparison with materials like carbon steel or plastic piping systems, stainless steel square pipes offer a superior strength-to-weight ratio without compromising on structural integrity. Industries such as petrochemicals and power generation heavily rely on robust piping systems capable of carrying fluids or gases at elevated pressures.

Heat Resistance of Stainless Steel Square Pipes

Besides their excellent corrosion resistance and mechanical strength, stainless steel square pipes also exhibit impressive heat resistance properties. They can withstand high temperatures without deformation or degradation, making them suitable for use in thermally stressed industries. In the field of chemical processing, for instance, stainless steel square pipes are often used for transporting hot or corrosive substances.

These pipes can withstand large temperature swings without losing structural integrity. Similarly, in the oil and gas industry, where pipelines might encounter high-temperature fluids during extraction or refining processes, stainless steel is the material of choice due to its ability to maintain shape and functionality under challenging thermal conditions.

Raw Materials of Stainless Steel Square Pipes

Stainless steel square pipes are fabricated using a combination of carefully selected raw materials. The primary elements utilized in the production of stainless steel include iron ore, chromium, nickel, and other alloying elements. The base component of stainless steel, iron ore, is what gives it its inherent strength and structure.

On steel surfaces, chromium creates a passivating oxide coating that inhibits rust and increases durability. Stainless steel’s resilience to high temperatures and hardness can both be increased by nickel. In addition to these core constituents, various other alloying elements are added in specific quantities to customize the properties of the stainless steel square pipes.

These may include molybdenum for enhanced corrosion resistance in harsh environments, titanium for improved weldability, or copper for increased strength.

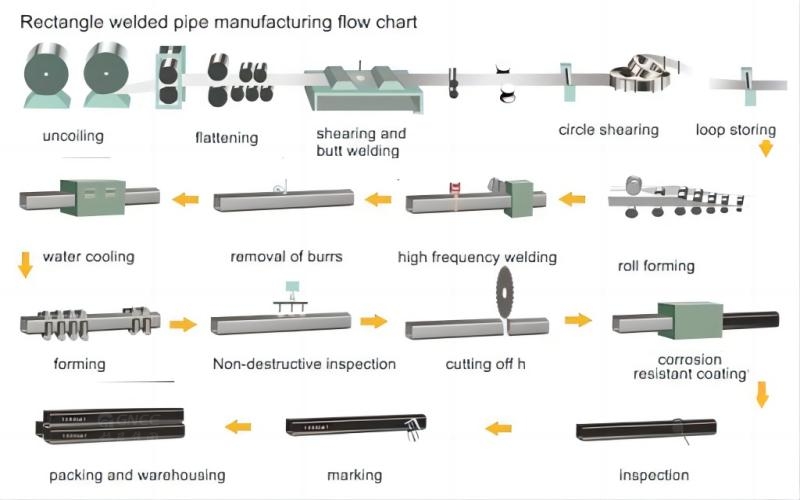

Forming Process of Stainless Steel Square Pipes

Once the solidified billets or ingots are obtained, they undergo a series of forming processes to shape them into square pipes. One commonly utilized technique is hot rolling, where the billets or ingots are heated to high temperatures and passed through a series of rolling mills. Through this procedure, the material’s length is increased while its thickness and width are decreased.

The repeated cycles of heating and rolling refine the grain structure, enhance mechanical properties, and create a precise cross-sectional shape that closely resembles a square. Alternatively, cold drawing can be employed to achieve similar results by subjecting the material to cold deformation below its recrystallization temperature.

During this procedure, heated billets or ingots are pulled through specially-made dies employing tensile forces. By carefully matching grain structures, cold drawing imparts great dimensional precision, enhances surface finish quality, and improves mechanical qualities.

Heat Treatment of Square Pipes

To further optimize their mechanical properties, stainless steel square pipes often undergo heat treatment processes. Annealing is one such technique that involves heating the formed pipes to high temperatures followed by controlled cooling. Through this thermal cycle, the material’s internal stresses are removed, its microstructure is refined for increased toughness and ductility, and its resistance to corrosion-induced cracking is strengthened.

Quenching is another crucial heat treatment method where stainless steel square pipes are rapidly cooled from high temperatures by immersing them in a quenching medium such as water or oil. High degrees of hardness can be attained while still maintaining other desirable qualities that were infused during previous production phases thanks to this quick cooling procedure.

Tempering is often performed after quenching to relieve any remaining internal stresses and attain the desired balance between hardness and toughness. This procedure improves ductility and decreases brittleness by warming the quenched pipes to precise temperatures, followed by controlled cooling.

What is Stainless Steel Square Pipe Used For?

Versatility in Architecture and Construction

Stainless steel square pipes are widely used in building and construction because of their versatility and aesthetics. They are often used as structural frames, handrails, railings, etc. Additionally, stainless steel square pipes are frequently utilized in the construction of high-rise structures, stadiums, and bridges.

Their high strength-to-weight ratio lowers material costs while enhancing the overall structural integrity of these structures. Additionally, because stainless steel can endure high temperatures, it can be used for chimneys in residential constructions or exhaust systems in commercial buildings.

Industrial Applications

Stainless steel square pipes have excellent performance and are widely used in various industries. For example, in the oil and gas field, they are used as pipelines to transport corrosive fluids or gases in high-pressure environments. Its corrosion resistance ensures the longevity of these pipes while maintaining the purity of the substances being conveyed.

In addition to oil and gas applications, stainless steel square pipes also find tremendous use in chemical processing plants. It can handle highly corrosive chemicals at varying temperatures and can also be used as piping for steam distribution systems within power generation facilities.

Food processing plants rely on stainless steel square pipes because they do not react with acidic or alkaline substances commonly found during food production processes. These pipes maintain hygiene standards by preventing contamination while facilitating efficient liquid or gas transfer within processing lines.