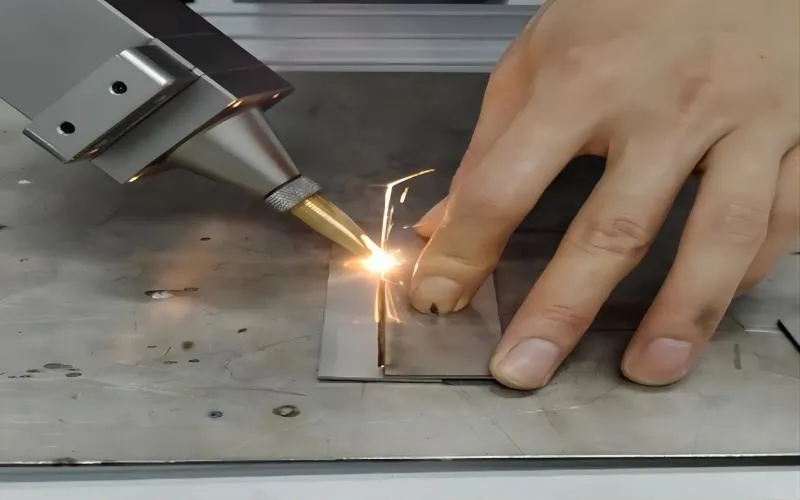

One sort of pipe that is frequently utilized is stainless steel pipe. Generally speaking, welding procedures must be completed before use to guarantee the product’s quality. We must learn the proper operation technique because it will help us in the future.

Before welding stainless steel pipes, the following preparations must be made:

1. When welding products, personnel must wear appropriate work attire and take preventive measures to ensure their safety.

2. You should determine whether the grinding wheel needs to be replaced or is loose before utilizing the electric grinding tool.

3. When operating on stainless steel pipes at high heights, safety belts must be used, and the scaffolding must be dependable and safe.

4. If working at a height and there are combustible or explosive materials below, precautions should be taken beforehand to avoid splashes from dropping.

5. Equipment with induction coils cannot be attached to the welding wire. To prevent arc damage to the steel pipe during work, the component attached to the welding clamp needs to be positioned steadily.

What are the stainless steel pipes?

The versatile material recognized for its durability and resistance to corrosion is stainless steel, which is used to make cylindrical tubes that are called stainless steel pipes. Important details regarding stainless steel pipes are as follows:

Distinctions from tubes

Although “pipe” and “tube” are sometimes used synonymously, they are not the same. Steel pipes are used to transfer gases and liquids, and they are commonly measured by their inner diameter (ID). Steel tubes, on the other hand, are measured using their wall thickness and outer diameter (OD). Tubes are frequently utilized as structural or architectural elements.

Different Grades

There are various grades of stainless steel pipes, including 304/L and 316/L. These grades’ corrosion resistance and other desired qualities are a result of the various amounts of chromium they contain.

Uses

Applications for stainless steel pipes can be found in many different areas and industries. The construction, modern architecture, pharmaceutical, oil and gas processing, water treatment, desalination, pulp and paper, brewing, shipbuilding, and energy industries are a few common applications.

Stainless Steel Types

Various types of stainless steel pipes can be distinguished by their composition and characteristics. Austenitic, ferritic, martensitic, duplex and precipitation-hardening stainless steel are a few popular varieties. Every variety has special qualities and uses of its own.

Welded versus seamless

Pipes made of stainless steel can be welded or seamless. Without any seams or weld joints, seamless pipes are constructed from a single piece of steel. Their resistance to high pressure and temperatures is well recognized. Contrarily, welded pipes are created by welding or attaching many steel sections. The particular use and needs will determine whether seamless or welded pipes are best.

Processes before welding stainless steel pipes

To guarantee excellent outcomes, there are a few crucial preliminary processes that must be followed before welding stainless steel pipes.

1. Pick the Proper Welding Material

Selecting the appropriate kind of weld material is essential for the successful welding of stainless steel pipes. Various weld materials offer distinct benefits based on the demands of the intended use.

2. Use Metal Filler with Low Carbon

Choosing a filler metal with a low carbon content is advised when welding stainless steel. This keeps the stainless steel resistant to corrosion and avoids problems brought on by applying too much heat.

3. Collective Arrangement

For welding to be successful, joints must be properly prepared. Usually, the pipes’ edges are cut to create a V- or J-groove bevel, which makes it simple for the weld head to access and promotes total fusion.

4. Tidy Up the Workpiece

Before welding, give the workpiece a thorough cleaning to get rid of any impurities that can lower the weld’s quality. Maintaining a clean and robust joint is important.

5. Manage the Heat Input

It is crucial to regulate the heat input during welding since stainless steel does not dissipate heat as well as mild steel or aluminum. Excessive heating might weaken the material’s resistance to corrosion.

6. Adhere to recommended procedures

Adhering to recommended procedures for welding stainless steel can enhance outcomes and preserve the metal’s ability to withstand corrosion. Enhancing the welding procedure can yield gains in production without sacrificing quality.