What Is Perforated Stainless Steel Plate?

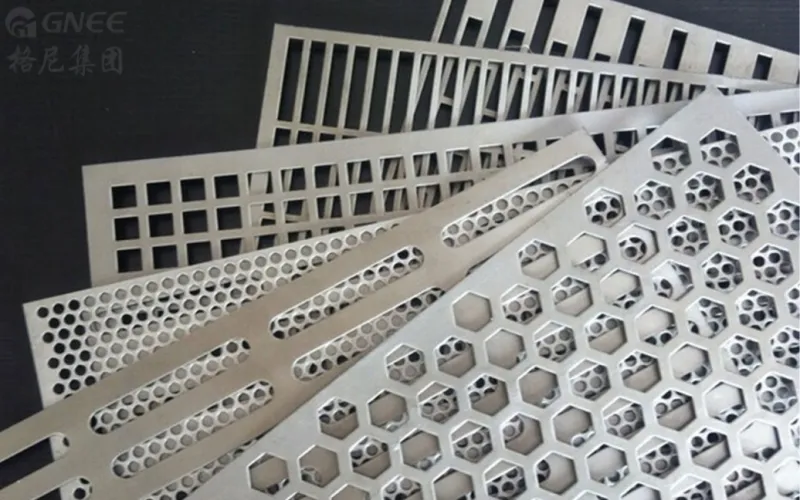

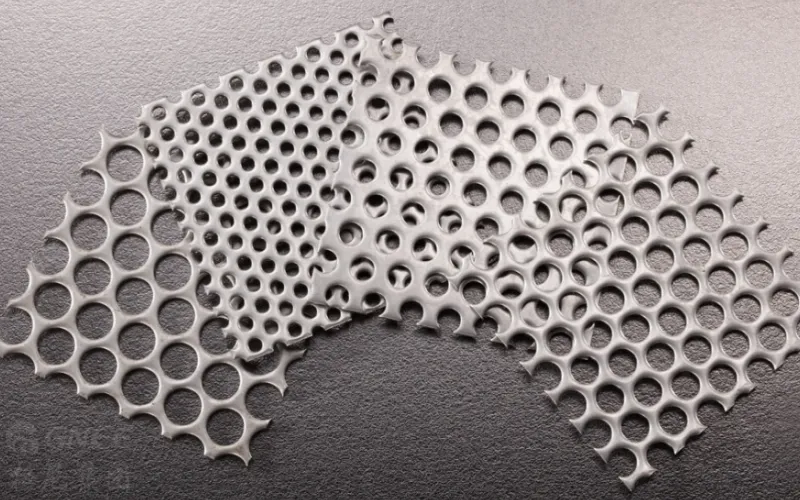

Perforated stainless steel plate, a marvel of modern metallurgy, greatly combines the strength and durability of stainless steel plate with the aesthetics and versatility of perforation. These holes are strategically placed across the metal surface by using advanced perforation techniques, imparting functionality and attractive appeal to the material. Additionally, the size, shape, arrangement, and density of these holes can vary significantly based on the customer’s specific requirements.

Nowadays, it has found wide applications in different industries, ranging from buildings and fencing panels to filtering systems. By allowing for the controlled passage of air, light, and fluids while retaining the whole structure, the perforated stainless steel metal has revolutionized the way we design and build.

Why Perforated Stainless Steel Sheet is Popular in the Steel Market?

1. Superior Corrosion Resistance: The plate is typically fabricated from austenitic or ferritic stainless steel. Austenitic stainless steel, such as 304 or 316, is widely used due to its high chromium and nickel content. Nickel improves the structural integrity and increases the resistance to corrosion and rust caused by chemicals or saltwater exposure. Ferritic stainless steel, on the other hand, possesses high levels of chromium but lower nickel content. They also exhibit comparable corrosion resistance but with improved strength characteristics.

2. High Strength & Structural Integrity: Perforated stainless steel sheets boast an impressive combination of high tensile strength and structural integrity, allowing them to withstand substantial loads without deforming or fracturing.

3. High Permeability: Compared with other stainless steel plates like stainless steel corrugated plates, stainless steel patterned plates, and stainless steel wire drawing plates, this sort of metal offers good permeability to water, air, and light. What’s more, it can be used as fencing material for your backyard, without obstructing your view to see what’s happening outside.

4. Various Patterns: It can be expected that perforated stainless steel metal has many attractive and unique hole designs. This adds a lot of beauty and charm to modern architecture.

5. Light Weight: All steel designs offer lightweight properties, and perforated stainless steel is no exception. More importantly, the perforations of perforated stainless steel can largely decrease the light of metal between 10% and 40%. That is, it can require less fuel, manpower, and money to transport it to your projects.

6. Green Solution: It improves both performance and cost-effectiveness. The perforated stainless steel plate can be either reused or melted to process other stainless plates. This makes significant contributions to environmental conservation and sustainable development.

Where Can Perforated Stainless Steel Plate be Used for?

Perforated stainless steel material can be applied across various sectors. For example:

In construction projects, these plates serve as essential components for facades or cladding systems due to their endurance and distinct appeal.

In engineering disciplines such as filtration systems or industrial equipment manufacturing, perforated stainless steel plates provide an ideal solution due to their corrosion resistance combined with precise hole patterns that allow controlled flows or screens for particle separation.

In transportation, it can be used in the manufacturing of radiator grilles, stair reads and risers, vessel components, car tuning, safety guards for machinery or equipment enclosures, and the like.

Finally, perforated stainless steel plates can be tailored for use in other applications including decorative screens, noise control panels, ventilation grilles, speaker covers, baskets, home appliances, etc.

How Is Perforated Stainless Steel Metal Made?

It uses the stainless steel plate as the substrate and the manufacturing process of perforated stainless steel can be either punched or cut.

Traditional Punching Method

One of the conventional methods employed in perforating stainless steel plates is through traditional punching techniques. Rotary punching machines utilize rotating drums or die with specific hole patterns to create perforations in a continuous fashion. This method allows for high production rates while maintaining constant hole quality throughout the plate’s surface. Turret punch presses represent another commonly utilized traditional method for creating perforations in stainless steel plates.

Laser Cutting Technology

In recent years, the rise of laser cutting technology has revolutionized the perforation process, allowing for ever more complex and intricate patterns. Two primary laser cutting methods employed for perforating stainless steel plates are CO2 laser cutting and fiber laser cutting. CO2 laser cutting involves a high-powered CO2 laser beam focused on the metal sheet’s surface. The intense heat generated by the laser vaporizes or melts the material, creating precise and clean holes. This method is particularly suitable for thicker stainless steel plates.

On the other hand, fiber laser cutting utilizes a fiber optic beam that is guided through flexible cables to deliver high energy density onto the material. Fiber lasers offer enhanced speed, accuracy, and efficiency compared to CO2 lasers, making them ideal for thinner stainless steel plates.

Perforated Stainless Steel Plate Manufacturer and Supplier

Whether it’s for architectural applications or industrial use, the versatility and durability of the perforated stainless steel plate make it an ideal choice. So, whether you’re designing an eye-catching building facade or engineering an efficient filtration system, incorporate the charm of perforated stainless steel plate to elevate your project to new heights.