Performance Comparison of Stainless Steel Pipes and Copper Pipes

1. Corrosion Resistance of the Two Pipes

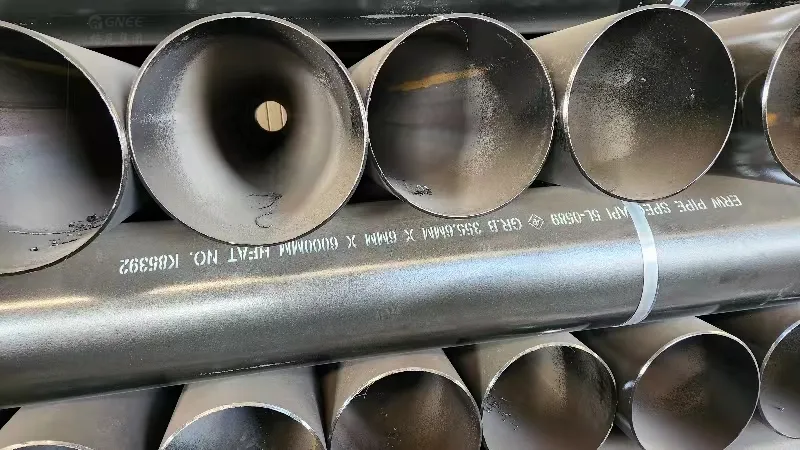

The ability of a material to withstand the corrosive effects of fluids or gases moving through it as well as any external corrosive forces is known as corrosion resistance. Due to the passive chromium oxide layer that forms on the surface of stainless steel and quickly regenerates itself when the surface is damaged, one of the most significant benefits of stainless steel is its resistance to corrosion, which makes it ideal in a variety of applications. resistant against corrosion.

When exposed to some common environmental conditions, especially in higher concentrations, copper can corrode. Gases such as carbon dioxide, sulfur dioxide, and hydrogen sulfide, “hard” water with a high chlorine or chloride content (which also corrodes stainless steel, but in larger proportions), and acidic conditions with a pH over 6.5-7.0 are some of these contributing variables.

Stainless steel often provides superior corrosion resistance to a wider range of gases and liquids, yet both stainless steel and copper will corrode under the correct conditions.

2. Strength and Durability

In strain and stress testing, stainless steel performs better than copper because it is typically 2.5 times stronger. 316 stainless steel pipe has a tensile strength between 570 and 620 Mpa, which is almost three times that of copper. It can endure high pressure and high temperature without any issues.

While easier to cut, bend, and more ductile than steel, copper is not appropriate for high-pressure or high-temperature applications.

3. Cost Comparison of Stainless Steel and Copper Pipes

Stainless steel pipe is typically the less expensive alternative in terms of cost. It can last for many years if maintained properly and is typically significantly less expensive than copper pipe. Steel pipes normally cost less upfront, but because of corrosion problems, they could need more frequent repair.

On the other side, copper pipes tend to cost more upfront but need less upkeep over time. The lifetime of copper is also remarkable; with proper maintenance, it can endure 50 to 70 years. As a result, copper pipes are generally a superior option in the long run.

4. Installation and Environmental Impact

Although it takes more effort and time, copper is a softer, more pliable metal that can be bent readily, eliminating the necessity for some tiny fittings. Stainless steel is good for long-term installations because of its strength and rigidity, frequently requiring less support than copper. Because the wall thickness can be reduced while maintaining the same pressure rating, stainless steel pipe may also be lighter than copper pipe, simplifying installation.

Additionally, stainless steel is a recyclable and environmentally friendly material. Its manufacture uses no hazardous chemicals, making it reasonably low-carbon and environmentally benign. Although copper is a low-carbon element as well, improper handling can lead to environmental degradation.

When are Copper and Stainless Steel Most Frequently Used?

Copper and stainless steel are both popular and dependable materials for ductwork. In residential, commercial, and light industrial plumbing applications, copper has been utilized for generations. Historically, stainless steel has been considered a “killer” for many applications because it is pricy, premium, and pricey.

Because of this, heavy industrial applications, the food and beverage industry, and the wastewater/water treatment industry have historically employed stainless steel pipes more frequently. Both materials, nevertheless, offer advantages. Stainless steel is more likely to be taken into consideration for applications where copper piping was formerly the “go-to” technology.

The following applications do not allow the use of copper:

Engine pipes: Fuel can polymerize in copper pipes, which thickens it.

High-pressure systems (restricted to copper pipe pressure ratings; as pipe size grows, pressure ratings drastically decline) accelerated systems Considering that the flow rate increases dramatically with the rate of corrosion. A copper pipe corrodes 20 times more quickly than stainless steel at a flow velocity of 6 m/s than it does at a flow rate of 2 m/s.

Advantages and Disadvantages of Stainless Steel Pipes and Copper pipes

Advantages and Disadvantages of Stainless Steel Pipes

Steel pipes have some benefits over copper pipes, one of which is that they are less prone to corrosion. Steel pipe is perfect for outdoor applications because it doesn’t freeze as easily in cold climates. Steel pipes are moreover typically less expensive than copper pipes.

Steel pipe, as opposed to copper pipe, has the drawback of freezing in cold weather, which can lead to issues with your plumbing and heating systems. In addition, steel pipes typically cost more than copper pipes.

Advantages and Disadvantages of Copper Pipes

The better heat and pressure resistance of copper pipe over steel pipe is one of its benefits. Additionally, copper pipes outperform steel pipes in terms of heat and electrical conductivity.

A further drawback of copper pipes over steel pipes is their greater susceptibility to corrosion, which can be problematic in exposed or outdoor applications.

Summary of the Differences Between Copper and Stainless Steel Pipes

Each material has its advantages and disadvantages, so it’s important to carefully weigh all your options before choosing one type of pipe over another for your specific needs. With proper research and planning, you should be able to find the best solution for your project without too much difficulty.