How To Store Stainless Steel Plates?

When storing stainless steel plates, it becomes of utmost importance to take all necessary precautions to prevent any unsightly scratches or damage. Here are some tips that will ensure SS plates remain in impeccable condition.

1. Choosing Suitable Warehouse

The first step to store stainless steel plate materials is of course to choose a suitable warehouse. The suitable site requirements are:

It is a clean, dry, and ventilated place.

It should be kept away from harmful gas sources and dust sources as much as possible.

There shall be no acid, alkali, salt, cement, industrial reagents, or other items near the stainless steel plates.

It should be isolated from carbon steel and carbon steel processing areas. If stainless steel and carbon steel are processed in the same workshop, carbon steel dust will fall on the stainless steel plate surface, which easily causes iron contamination on the stainless steel plate surface.

In general, the stainless steel plate material warehouse should adopt a closed warehouse.

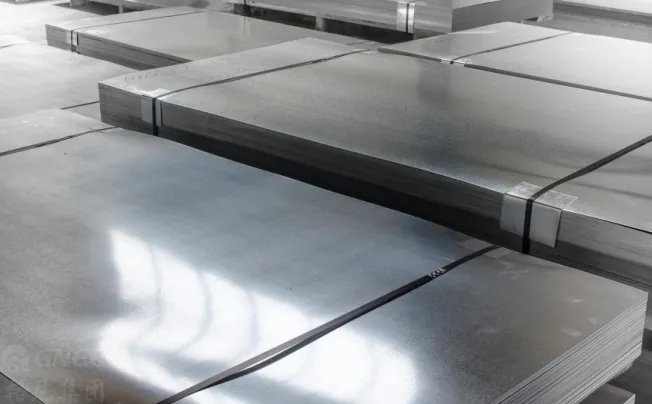

2. Utilizing Specialized Storage Racks

Storage racks can be the most practical and convenient option for stainless steel plate storage. These racks allow the plates to be stored vertically, thereby saving precious space and reducing the peril of unsightly scratches or damage. And it is also easy to put or lay down the plates.

The storage racks should be wooden or painted steel brackets, or padded with rubber pads to isolate them from other metal materials such as carbon steel to avoid dust, oil, and rust from corroding the stainless steel surface.

3. Considering the Plate Protectors or Dividers

Plate protectors or dividers, serve as an excellent means to prevent the unfortunate rubbing together of stainless steel plates, which often results in unsightly scratches. These protective accessories can be placed between each plate, thus creating a cushioning barrier. Therefore, these protectors or dividers should be crafted from soft materials, such as felt or foam, which can ensure the gentlest protection for your stainless steel plates.

4. Avoid Overcrowding

It is of paramount importance to refrain from overcrowding the storage area where the stainless steel plates are kept. Overcrowding may lead to unfortunate accidents such as plates falling or being inadvertently bumped into. Such incidents can result in undesirable outcomes, including unsightly scratches, dents, and even injuries. Therefore, it is imperative to ensure that there is ample space between stacks of plates, allowing for safe handling and retrieval, thus mitigating the risk of any untoward incidents.

Precautions for Storing Stainless Steel Plates

1. During storage, attention shall be paid to moisture, dust, oil, etc., to avoid rust on the surface of stainless steel plates.

2. When water is immersed between the film and the stainless steel plate substrate, the corrosion rate is faster than that without film.

3. The stainless steel plate coated with the film shall be protected from direct sunlight. And the film shall be inspected periodically. If the film has deteriorated (the service life of the film is 6 months usually), it shall be replaced immediately.

4. If the packaging material is wet when adding padding paper, the padding shall be removed immediately to prevent surface corrosion.

5. Stainless steel plates can be stored outdoors and even be placed in a covered outdoor warehouse if necessary. But it is necessary to avoid exposure to sea salt, de-icing salts, and air pollutants such as acid mist and grinding dust.

6. When storing, the storage location should be convenient for lifting, and relatively isolated from other material storage areas.

7. Stainless steel plates should be inspected frequently after being put into storage. If there is any rust, the rust layer should be removed.

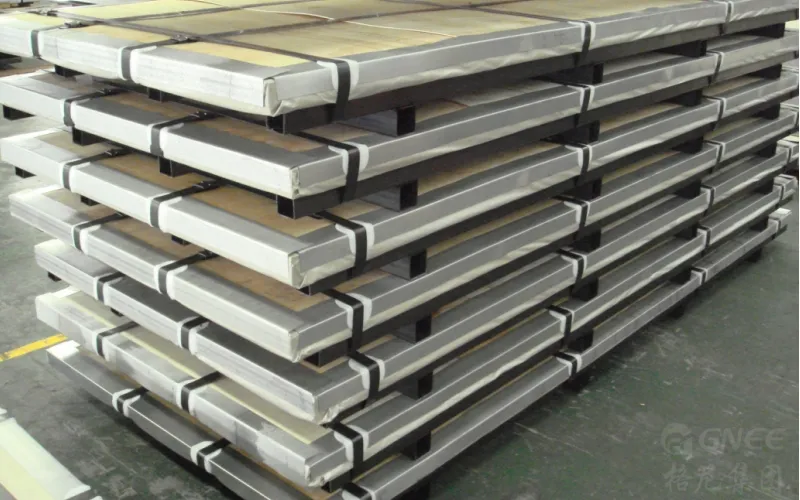

8. For some users with a larger storage capacity of stainless steel plate materials, there are some other storage rules. For example:

Stacking according to the cross-section of stainless steel plates or stacking and storing together according to different furnace numbers (also known as batch numbers);

Secondly, pay attention to making the stainless steel plates stacked as neatly as possible, and their symbolic ends face one direction, which is convenient for identification and search. When necessary, related shims or metal racks can also be used to make the storage of stainless steel materials more stable and effectively prevent the storage pile from tilting, shifting, or sinking.

FAQ Concerning the Storage of Stainless Steel Plates

1. Can Stainless Steel Plates be Stacked without any Protection?

It is ill-advised to stack stainless steel plates without any protection. Though stainless steel is renowned for its durability and resistance to corrosion, stacking plates without proper safeguarding may result in unsightly scratches, dents, and other forms of damage. To avert such calamities, it is recommended to interpose a layer of protective material, be it cardboard or foam, betwixt each plate whilst stacking them. This shall serve to cushion the plates and minimize the peril of surface damage.

2. Is It Necessary to Store Stainless Steel Plates in a Specific Manner?

Indeed, it is important to store stainless steel plates in a specific manner to uphold their quality and prevent any harm from befalling them. At the same time, it is easy to put in or out.

3. How Frequently Should Stainless Steel Plates be Inspected for Damage?

Regular inspections are of the essence to detect any damage or potential issues with stainless steel plates. The frequency of inspections may hinge upon various factors such as the environment, usage, and handling of the plates. Nevertheless, a general guideline stipulates that the plates be inspected at least once every six months. During the inspection, meticulously scrutinize the plates for any signs of corrosion, scratches, dents, or any other visible damage. Swiftly address any issues that arise, to forestall further deterioration and ensure the longevity of the stainless steel plates.

Conclusion

In summary, although stainless steel plate has strong corrosion resistance and long service life, it also requires good storage and maintenance by the supplier/user. That can greatly extend the use efficiency of stainless steel plate products, thus creating tremendous benefits.