Why Need to Make/Form Patterns on Stainless Steel Plate?

1. Slip improvement or slip resistance. The patterns will provide a non-slip and raised surface that makes them ideal for use in areas where safety is a concern. It makes the plate ideal for use in stairways, pathways, catwalks, trailers, truck beds, etc.

2. Surface quality improvement. Compared with plain stainless steel metal, it is processed by different patterns of raised diamonds to add extra beauty to your projects.

3. Excellent scratch resistance. The raised design makes the plate uneven and more wear-resistant than other finishes, making it ideal for use in harsh environments.

4. High toughness. The raised pattern makes it have a stronger load-bearing capacity than substrates of the same thickness.

5. Great durability. Using stainless steel plate as substrate, it also has a long lifespan of more than 50 years.

6. A wide variety of designs. These sheets come in a variety of grades, sizes, thicknesses, and pattern designs to meet specific requirements.

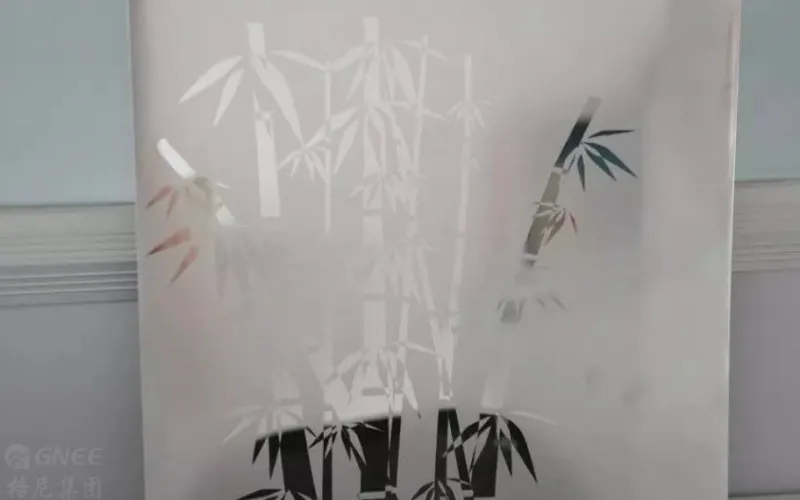

7. High Recognition.Thanks to its unique design to produce strong visual impacts, it can leave an enduring impression on everyone they come into contact with. In the realm of decoration, patterned stainless steel sheets and plates take center stage, embracing artistic and religious motifs.

8. Easy cleanliness and maintenance. It is easy to clean and maintain just like other stainless steel products.

How To Make Patterns on Stainless Steel Plate?

There are many ways to make patterns on stainless steel plates, including carving, milling, embossing, stamping, etching, sandblasting, etc. Let’s have a closer look now!

1. Hand Carving

It is to use a diamond blade to carve various patterns on the stainless steel plates by hand. This method usually results in poor pattern accuracy, high labor intensity, and low work efficiency. Therefore, hand carving is suitable for plates with uneven surface decoration that does not require high precision.

2. Sandblasting

It is to use compressed air to spray high-speed emery on the surface of the stainless steel plate blocked by the pattern template to form sand patterns. The surface produced by the sandblasting method is relatively rough and it is difficult to spray thin strips. The depth generally does not exceed 0.08mm.

3. Mechanical Milling

It is to use mechanical equipment, such as engraving machines, profile marking machines, or copiers to operate rotary tools for milling. This method can only be engraved on flat stainless steel plates and is easy for deep milling. The operation cost of mechanical milling is expensive but offers a strong three-dimensional effect.

4. Embossing

It is produced by rolling a coil of stainless steel straight into the embossing mold to form designs on the coil surface. Then the coil will be cut into sheets. It should be noted that this type has been pattern-pressed into a raised design on one side of the product. The other side is flat. The patterns are mainly Belgian flowers and Japanese fine flowers.

5. Stamping

With stamping, the stainless steel plate is passed between a series of large patterned rollers and mechanically stamped into patterned designs. This process creates concave and convex designs on the surface of the stainless steel plate. As the patterns are different, the depth of the concavities and convexities on the plate is also different. The commonly used pattern molds of this type are mainly lentil flowers and round bean flowers and the thickness of the stainless steel plate is about 2-5mm (too thin will directly cause the plate to deform). Generally speaking, the scratch resistance of the stamped plate is 80% higher than that of the embossed plate.

Another thing that should be noted is that both embossing and stamping are the two main processing methods to fabricate stainless steel patterned plates nowadays.

6. Etching

Etching is to use an auxiliary electrode in an appropriate electrochemical etching solution to erode the surface of the stainless steel plate that has been covered with a patterned resist film to obtain an etched pattern. After removing the film, a pattern with higher precision will be obtained. Its etching speed is also faster, and suitable for mass production. But it requires the use of specialized instruments and equipment.

The etching process can be used to produce textures that have varying depths and sizes as per your request.

7. Other Methods

Of course, in addition to the above commonly used methods that directly form patterns on the surface of stainless steel plates, there are also thermal transfer and lamination sheets that are slowly being accepted by the market. Moreover, with the development of stainless steel processing technology, new processes will continue to emerge, and stainless steel plates will become more and more popular.

Looking To Buy Patterned Stainless Steel Plates?

Gnee Steel Co., Ltd. is a comprehensive stainless steel corporation integrating design, processing, manufacturing, and trade. Our factory is committed to the development and research of the surface of stainless steel plates. At present, the factory has the most advanced complete set of production equipment, production experience, and technology for surface treatment of stainless steel plates. Adopting a strict quality management system and product testing, we adhere to the business philosophy of quality first and excellence. Due to our more than 15 years of experience in production, we ensure that we can offer the best advice for the design of your project. Contact us today to learn more about this unique and versatile product or get free samples!