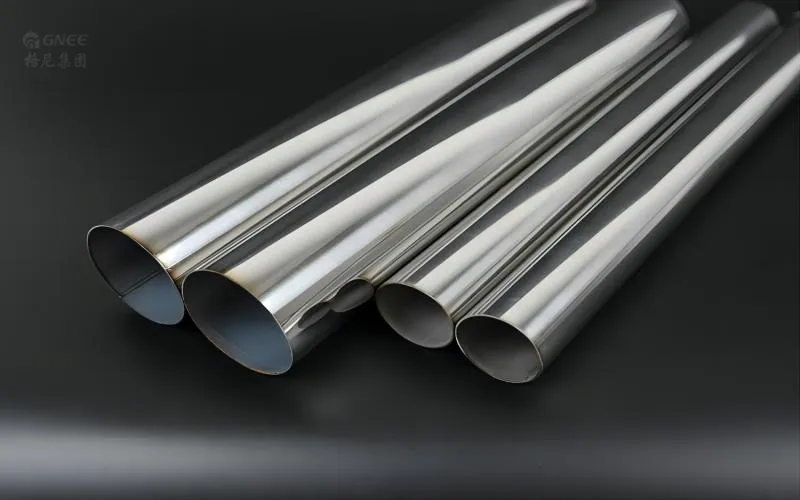

What Is a Stainless Steel Pipe?

A hollow, oblong steel with other components like nickel, manganese, and molybdenum added to improve its qualities, stainless steel tubing is formed of iron and chromium. It is used in petroleum, chemical, medical, food, light manufacturing, and other areas because of its exceptional corrosion resistance and suitability for a wide range of applications involving the transmission of fluids or gases.

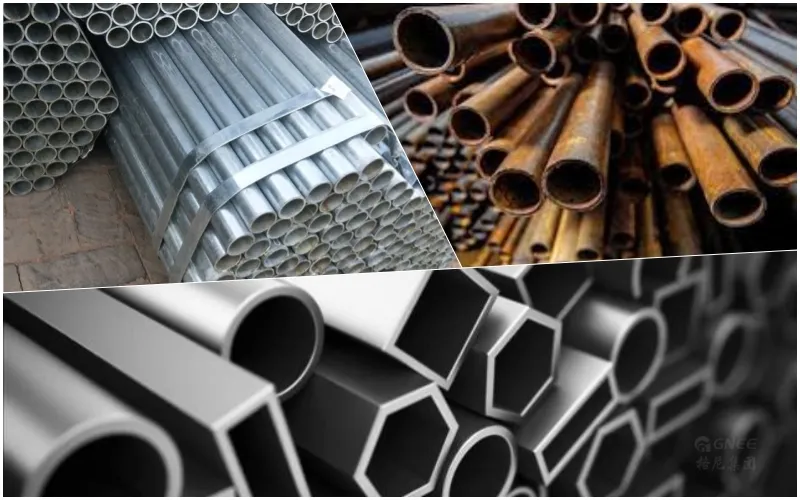

The alloy metal tube is shielded from the outside environment by a thin layer of chromium plating, thus the external environment has no impact on or injury to the inside environment. Additionally, to accommodate various requirements, stainless steel tubes are offered in a range of sizes and shapes, including round, square, and rectangular tubes. To establish piping systems that can effectively carry fluids or gases safely and dependably, they are typically utilized in conjunction with fittings and couplings. Consequently, stainless steel tubes are highly sought after in the market, with 304 and 316 stainless steel tubes being the most popular due to their high-quality attributes and dimensional variances. These types of stainless steel tubes have various levels of corrosion resistance, strength, and other characteristics depending on the particular requirements of the application.

In conclusion, stainless steel tubes are preferred because of their resistance to corrosion, strength, durability, and versatility. They are well-liked not only in China and India but also around the world.

Why Is It Called Galvanized Pipe?

Steel pipes that have been galvanized—a protective layer of zinc applied to stop rust and corrosion—are made of steel. Galvanizing became popular after it was found that lead poisoning could be induced by regular lead pipes. The steel pipe is dipped into a molten zinc solution during the galvanizing process, which creates a metallurgical bond with the pipe’s surface. The steel pipe is shielded from moisture and other corrosive substances by this covering of zinc.

Plumbing systems frequently employ galvanized pipes, particularly in older homes and structures. Because they were affordable and durable, they were well-liked in the past. Galvanized water supply pipes became the most popular type of material used to supply homes with drinking water from the end of World War II until 1960. The underlying steel may rust and corrode as a result of the zinc covering degrading and becoming damaged over time. Plumbing issues like leaks, discolored water, and low water pressure may result from this.

1. Water leaks: Rust or corrosion on the pipe’s exterior, typically near the joints, might eventually cause leaks.

2. Water that is discolored: Iron and minerals in pipes can cause water to turn brown. Brown spots next to faucets may potentially be a sign of rusted pipes.

3. Reduced water pressure: Corroded pipes may hinder the flow of water. Low water pressure may ensue as a result.

Potential health complications can result from any of the aforementioned conditions.

What is Cast Iron Pipe and Why Do We Use It?

Grey cast iron is the main material used to make cast iron pipes. Cast iron (CI) piping was commonly used to transmit water and sewage until plastic piping was created. One of the oldest pipeline systems still in use today is made of cast iron, but high-density polyethylene (HDPE) and polyvinyl chloride (PVC) pipes have taken their place. Although most cast iron pipes need to be replaced due to deterioration, some of them are still in service.

Because of its durability and long-lasting performance, cast iron pipes are frequently used in DWV (drainage, waste, and ventilation) systems, which are employed in older homes and structures. Cast iron sewer pipes with correct installation can last for more than a century. Cast iron pipes are created by melting pig iron, a significant amount of scrap metal, and other materials, then pouring the molten metal into molds to form the pipes’ thick walls. The resulting cast iron pipe can handle low wastewater pressures even if corrosion occurs, has strong resistance to external loads, and is appropriate for underground installation.

Cast iron pipes will corrode over time, however, rust will eventually build up on the exposed pipe, slowing down corrosion. Cast iron pipe is still an excellent option for putting pipes in homes because of its advantages, but it is no longer as common because of the more affordable, less expensive alternatives presently available.

How Do You Distinguish Them from the Naked Eye?

1. Examine the Material

Because the primary material in cast iron pipes is iron, which corrodes and rusts easily at room temperature, cast iron pipes outside typically have a more durable anti-corrosion covering, typically asphalt paint or silver powder paint. Epoxy resin paint is another option, so the color and texture of the paint are what you can see and feel.

To achieve the stainless steel color, the stainless steel tube is mostly made of alloy steel, which is resistant to rust at room temperature despite its name. As can be seen, the dazzling ornamental stainless steel has essentially been polished.

The exterior of the steel pipe that has been galvanized with zinc is coated. The outer layer of galvanized steel is intended to protect the pipe because regular steel pipe (technically referred to as welded steel pipe) and cast iron pipe are easily prone to rust and corrosion at room temperature. Typically, the color of the galvanized layer is visible.

2. Consider the Connection

While socket connections, clamp connections, flange connections, etc., look obvious, a cast iron pipe is not welded.

In theory, it is forbidden to weld galvanized steel pipe because galvanic corrosion will occur between the solder and the galvanized layer and welding will remove the galvanized coating. As a result, the connection is frequently made using a wire, a clamp, or a wire flange.

The majority of stainless steel pipe is welded, however, there are also welded flange connectors and clamp connections. The wire is difficult to set because of its strength.

3. Before making a purchase, it is important to thoroughly consider the manufacturing standards, models, specifications, and other aspects of pipes.