How To Choose Stainless Steel Plates?

When choosing stainless steel plates, there are several factors to consider to ensure you select the right ones for your needs. Here are some key points to keep in mind.

1. Using Purpose

Before selecting stainless steel plates, the purpose and use environment of stainless steel plates should be considered. Are they for everyday use, special occasions, or outdoor activities? This will help determine the appropriate size, weight, grade, and durability required for the plates.

Generally, 200 series stainless steel plates can be used indoors, and grades such as 304 should be used outdoors. In acidic and alkaline places or coastal areas, grades above 316 are generally used.

And for medical treatment or kitchens, sanitary stainless steel plates tend to be chosen.

2. Material Quality

When selecting stainless steel plates, it must be determined that the material meets the standard. Take the 304 material as an example:

1. From the price analysis, if the 304 stainless steel plate is even lower than the general price of the 201 stainless steel plate on the market, it is necessary to carefully identify that: it is likely to be impersonated by other materials;

2. Identify whether there is a steel stamp “304” on the surface of the plate. The manufacturer’s quality certificate should be obtained as a certificate at the same time;

3. 304 SS plate can be tested with an acid reagent. After 30 seconds, material 304 will not change color, and material 201 will turn black;

4. For bulk purchases, samples can be taken and sent to the national authoritative testing center for ingredient testing.

3. Design

Consider the design and style that best suits your preferences and complements your existing projects. Various options are available, whether you prefer a modern, minimalist look or a more traditional style. For example, it includes stainless steel corrugated plate, stainless steel patterned plate, stainless steel perforated plate, stainless steel wire drawing plate, and stainless steel clad plate.

4. Thickness

As we know, thicker stainless steel plates provide better strength and stability and add more weight and cost. Thinner stainless steel sheets, on the other hand, are more flexible and lightweight but may compromise performance and durability. Therefore, choosing the right thickness is a good starter to determine the application and the structural or design requirements. Here’s a general guideline for the thickness options available, along with their common applications:

0.8 mm to 3.0 mm: suitable for decorative and artistic purposes, such as wall cladding and fabrication of sculptures, jewelry, and kitchen utensils.

3.0 mm to 12.5 mm: ideal for industrial applications such as construction, manufacturing, and mechanical engineering, where heavy-duty performance is essential.

12.5 mm and above: mostly used for extreme conditions such as offshore, marine, and mining industries, where safety and reliability are critical.

Nevertheless, it’s important to ensure that the thickness of the steel complies with local regulations and industry standards that dictate the minimum thickness required for food packaging.

5. Size

Stainless steel plates come in different sizes, with varying lengths and widths. The standard size options available on the market are typically in feet or meters, depending on the supplier’s location and operating standards. Here’s an overview of the most common size options for stainless steel plates:

Length: 2400 mm, 3000 mm, 6000 mm, and 8000 mm

Width: 1200 mm, 1250 mm, 1500 mm, and 2000 mm

Custom sizes for stainless steel plates are also possible, depending on the supplier’s capabilities and the customer’s specifications. It’s essential to check with the supplier for their custom size options and availability before placing an order.

6. Grade

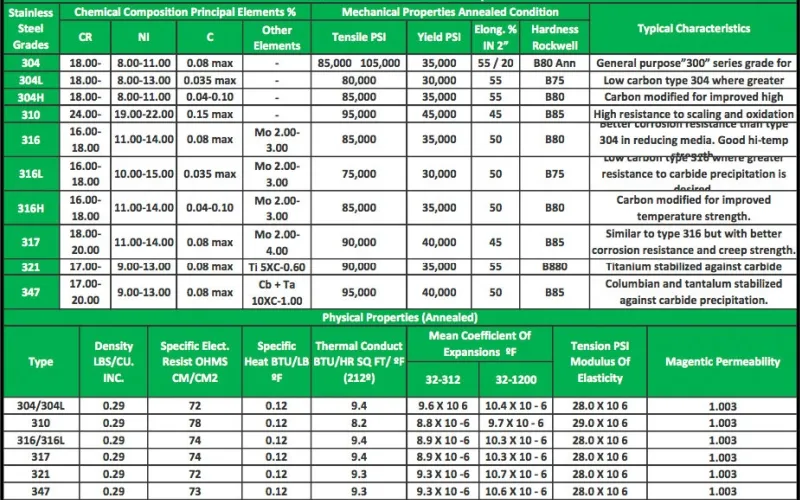

It is also important to know the critical differences between stainless steel grades. Various grades have unique characteristics that make them ideal for specific applications. Many manufacturing and construction projects depend on specific stainless steel materials, and that is why it is essential to understand and compare grades before purchasing stainless sheets and plates.

For instance, if welding is your chief concern for your stainless steel plates, the 304 stainless steel offers durability and strengthening capabilities. It is a stainless steel grade that performs at relatively high temperatures making it ideal for industrial, architectural, and transportation applications. In comparison, 316 stainless steel is optimal for applications requiring more extreme corrosion resistance. Due to the increased molybdenum content in its composition, it increases the corrosion resistance but is not as easy to machine. This material is typically used in applications with proximity to corrosive environments such as acids, chemicals, and salt water.

7. Finish

In addition to the many grades of stainless steel, the sheets also come in a variety of finishes depending on the application that stainless steel is used for. The finishes are numbered or alpha-coded: 1, 2B, 2D, 2BA (or simply Bright Annealed) 3, 4, 6, 7, 8, and TR for Temper Rolled.

The #4 brushed finish is the most common. Easily recognizable, you’ll find the finish on nearly all stainless steel appliances. The brushed look has a bright finish and is characterized by short, uniform, parallel polished lines, with a visible directional “grain.” It is designed for daily use and to hide scuff marks, fingerprints, scratches, etcetera.

The #8 mirror-like finish has the most reflective, highly polished surface of any stainless steel. The finish is arrived at by polishing with successively finer abrasives and then buffing extensively until all grit lines from preliminary grinding operations are removed.

8. Budget

Determine your budget for the stainless steel plates. There are options available at different price points, so consider the balance between quality and cost.

9. Stainless Steel Plate Supplier

Choosing a reliable and reputable stainless steel plate supplier is essential to ensure quality, availability, and customer service. Here are some tips on how to choose a stainless steel supplier:

1. Quality and Reputation: the supplier should have a good reputation for supplying high-quality stainless steel products that meet industry standards.

2. Pricing: while it is important to consider the cost of the stainless steel products, do not base your decision solely on pricing. Choose a supplier that offers a fair price for high-quality products and reliable services.

3. Certifications: a reliable supplier should have certifications such as ISO 9001 and other quality control systems to ensure their products meet the required standards.

4. Experience: a supplier with considerable experience in the field can provide valuable insights and solutions to your specific situation.

5. Delivery and Lead Times: check that the supplier can deliver the products you need on time, with reliable and fast shipping and handling services.

6. Customer Reviews: checking online reviews and testimonials from previous customers can provide valuable feedback and insights into the supplier’s performance and reliability.

In China, there are many big brand stainless steel suppliers, such as Taigang, Baosteel, and some high-quality private steel mills that are good choices like Gnee Steel.

Buy Stainless Steel Plates from Gnee Steel

Gnee Steel is a stainless steel fabricator and supplier with more than 15 years of development and experience. We can offer stainless steel plates in a wide selection of grades, cuts, sizes, thicknesses, patterns, and finishes that can be customized to suit customer’s specific projects. If you can’t find the wanted size or grade for your stainless steel plates, feel free to contact us for assistance at +8618437960706.