What Is Stainless Steel Plate Bending?

Stainless steel plate bending is the process of forming the stainless steel plate into specific shapes. This can be achieved through the use of a press brake, punching machine, ironworker, or other machinery.

Why Bend Stainless Steel Plate?

Bending stainless steel sheets has numerous benefits, making it a popular choice for those looking to customize their products or projects.

First, stainless steel plates have excellent corrosion resistance, which means they do not corrode easily even when exposed to moisture or other harsh elements like UV rays or extreme temperatures. So when you bend your stainless steel plate into shapes, you won’t have to worry about rusting or other signs of corrosion over time.

Another benefit is that, even after being bent into various shapes, the metal will still retain its strength and will not lose any of its structural integrity over time. This makes it an ideal choice for projects that require resistance to wear and tear over time.

How To Bend Stainless Steel Plates?

Here are the general steps involved in bending stainless steel plates:

1. Prepare the stainless steel plates. All must be inspected to be good and clean.

2. Mark the Bend. Measure and mark the bend location along one edge of the stainless steel plate with the tape measure and awl. Place a second bend mark on the edge of the stainless steel sheet parallel to the edge you just marked.

3. Wear the protective suit. Put on your safety glasses, gloves, and clothes.

4. Select the correct tooling. There are several different methods available for bending stainless steel plates. Depending on your project requirements and budget constraints, you can choose from a variety of techniques, such as manual forming (using hand tools), press brake forming (using presses), or cold rolling (using machines). Each technique has its own set of pros and cons that should be weighed carefully before deciding on which method to use for your specific project needs.

5. Set the parameters. Adjust the parameters of the press brake or bending machine according to the thickness and dimensions of the stainless steel plate.

6. Perform the bending process. Carefully execute the bending process, ensuring the plate is bent to the required angle without causing damage.

7. Inspect the result. After bending, inspect the stainless steel plate to ensure it meets the required specifications and tolerances.

Considerations for Bending Stainless Steel Plate

1. Plate thickness. Before bending the stainless steel plate, it is essential to determine the thickness of the plate. Thicker plates require greater bending force, so the bending force of the press brake should be considered in advance.

2. Bending angle. Stainless steel plate has high tensile strength, low elongation, high bending force required, and large bending angle.

3. Bending radius. The larger the bending radius, the more rebound will also increase, so when bending stainless steel sheet, the bending radius and bending angle should not be too small, otherwise bending cracks will occur.

4. Bending rebound. Due to the higher yield strength of stainless steel compared to carbon steel, the elastic recovery is greater. There may be inconsistencies in the bending angle, bending radius, and mold size. Therefore, using a sharper Upper punch produces a smaller bending radius and reduces sheet rebound.

5. Calculating the bending allowance. The bending allowance, which is the expansion of the outer side of the plate, can be calculated with the knowledge of the sheet thickness, bending angle, and inner radius.

This calculation determines the required length of the plate for bending.

The formula for calculating the bending allowance is: BA=(π/180) x B x (IR+K x MT), or use a bending allowance gauge.

Three Common Ways Of Bending Stainless Steel Plates

1. Bending by Hand

For thin and small stainless steel sheets, we can bend them by hand. The prepared auxiliary tools include marking pens, angle rulers, rulers, flat pliers, and hammers.

Firstly, calculate the bending allowance, mark the bending line with a ruler and marking pen, and then cut the size of the sheet. Clamp the sheet tightly with flat jaw pliers, and use a hammer or manual bending to the size. Use an angle ruler to check and repeat the operation until the bending is completed.

2. Hot Bending

For thick stainless steel plates, we need to heat the plate and perform hot bending. Put the sheet metal into the hot press machine, the machine will heat the sheet metal with high frequency, and shape it by hot pressing with the mold. This method requires customized molds for mass production.

3. Cold Bending

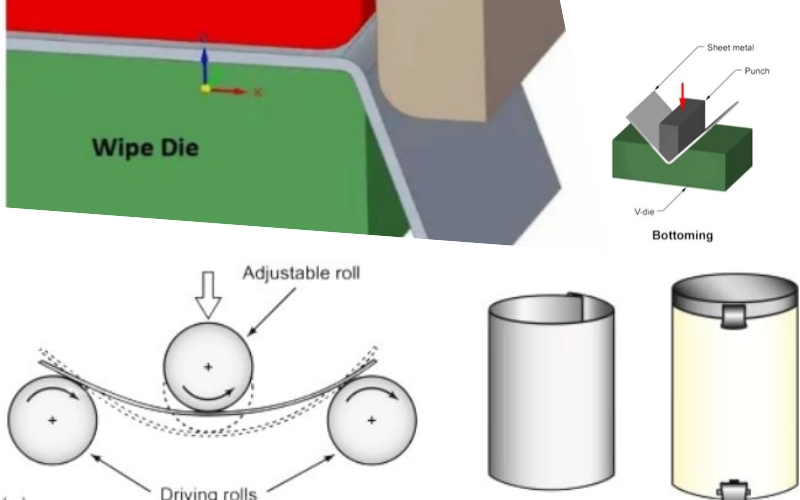

In cold bending, hydraulic press brake and hydraulic rolling machine are usually needed.

The hydraulic Press brake can use the upper punch to apply downward pressure to bend the stainless steel sheet surface to the specified angle. During bending, the ratio of the sheet thickness to the notch of the lower die of the Press brake also needs to be considered. Generally, choose die channel (V) = thickness (T) × 8.

What Are the Different Types of Stainless Steel Plate Bending?

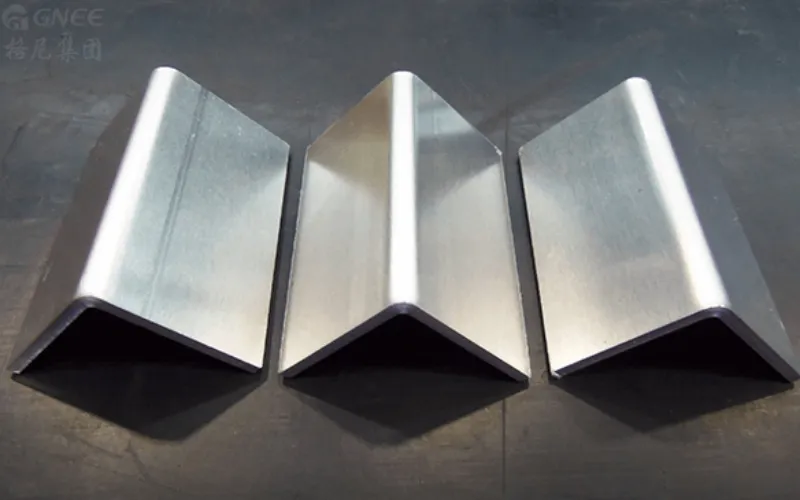

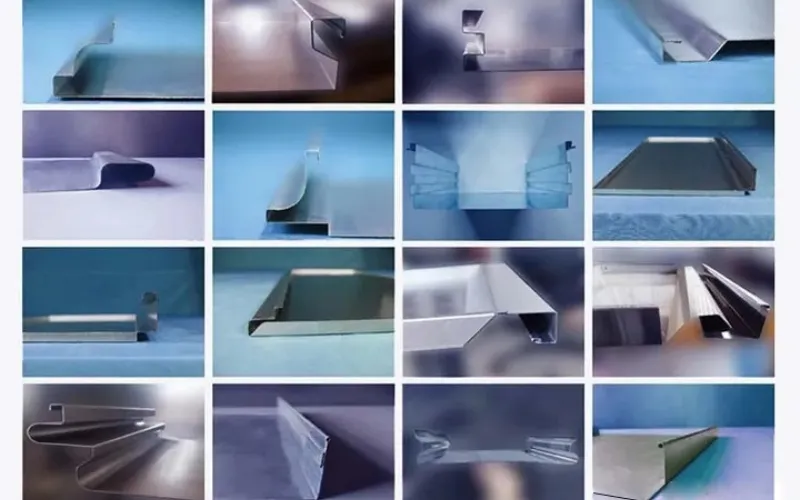

The stainless steel plate bending process can result in different bending shapes based on the angle and radius of the bend. Let’s take a look at some of the main bending types in stainless steel plate bending.

1. V bending. This is the most common bending process and is named so because of the V-shaped punch and die used in the process. The punch presses the metal sheet into the lower die, resulting in a V-shaped workpiece.

2. Bottoming. The Upper punch completely presses the metal sheet into the Lower die, so the angle of the mold determines the final angle of the workpiece. Bottoming can reduce sheet rebound and provide good accuracy.

3. Air bending. Air bending provides greater flexibility, helping you achieve results between 90 and 180 degrees with multiple bends as adjustments. Of course, its accuracy will be lower than Bottoming’s.

4. Coining. Coining has been popular in the past, but with the development of CNC Press Brake, its application has gradually decreased.

5. U bending. U bending is similar to V bending in that it also uses the Upper punch to press down on the Lower die. But its shape is U-shaped and is mostly used for manufacturing U-shaped channel steel.

6. Step bending. Step bending is the multi-V bending, which can make the workpiece bend a large radius, but also can perform several small V bending in succession.

7. Roll bending. This process is used for bending workpieces with large curls and involves the use of three rolls driven by a hydraulic system to bend the sheet. For example, it allows the sheet to be bent into tubes and cones. If necessary, large radius bending can also be manufactured, which can be rolled once or multiple times simultaneously.

8. Wipe Bending. This method is similar to edge bending, namely bending the edge of sheet metal, and the width bending tool also determines the inner radius of the bending. The plate is placed on the lower die and pressure is applied to the protruding metal by a pressure pad and punch, resulting in bending.

9. Edge bending. This method involves the use of upper and lower molds that move up and down for bending. It’s usually used for shorter stainless steel plates to reduce sharpness and prevent damage to the bending edge.

10. Rotary bending. This method can bend the workpiece with a degree of more than 90. The final profile is similar to a V-bend, but the profile surface is smoother.

Conclusion

Bending stainless steel plates can be an excellent way to customize your project or product according to your needs and preferences. Reading this blog, you will get a lot to ensure that your project turns out exactly how you want it while minimizing potential damage or warping due to improper techniques. If you want further talk, welcome to contact our technical team: Whatsapp: +8619949147586.