How Should An Adjustable Pipe Cutter Be Used?

1. Close the jaws tightly around the pipe

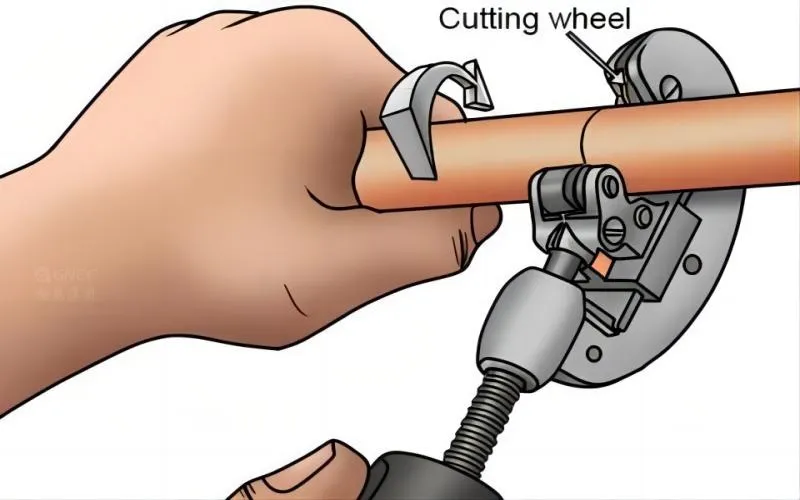

Press the pipe cutter’s rollers up against the pipe. Once the cutting wheel touches the opposite side of the pipe, turn the tightening screw in a clockwise direction.

An adjustable pipe cutter is mainly used for metal pipes and resembles a wrench. The jaws feature a cutting wheel on one side and rollers on the other to hold the tool in position on the pipe. The breadth of the jaws is adjustable with a screw on the side of the tool or the handle end. Place the pipe cutter with the open side facing upward if the pipe is horizontal. Before making any cuts, clamp or use a vice to fasten any loose pipe to a workstation.

2. To create a test groove, rotate

After making contact, give the screw one more quarter turn of tightening. Rotate the cutter 360 degrees around the pipe using the handle. This action ought to create a smooth, round groove in the pipe.

If the tool has a spiral groove, it is going off course. Verify that the pipe cutter is made for the material you are cutting, and try using a wire brush and tool cleaner to clean the cutting wheel and rollers. Should it continue to cut unevenly, it may be necessary to swap out the cutting wheel.

3. Twist and tighten several times

Now turn the tool 360 degrees around the pipe and tighten the screw until you feel tension. To progressively drive the cutting wheel through the pipe, repeat this action.

Since pressing the cutter into the pipe can harm your tool, it is preferable to tighten it too little rather than too much. For each rotation, or even every other rotation, try giving the screw just a 1/4 turn.

To engage the pipe in various positions, some exotic pipe cutters have numerous wheels or blades along the jaws. Because they allow you to rotate the tool back and forth along a smaller arc rather than in complete circles, these are excellent for tight spaces.

When Is It OK to Use A Pipe Cutter Rather Than A Hacksaw?

1. When you require a smooth surface, use a pipe cutter

The cut made by the pipe cutter is smooth and largely burr-free. This works well for any plumbing pipe, but it’s especially useful for plastic or metal pipes that you want to solvent-weld or solder. A hacksaw creates a jagged edge that requires additional labor to sand and deburr before bonding can occur.

2. An adjustable pipe cutter is best when making precise cuts

To cut a precise circle, align the pipe cutter once at the beginning. For many applications, this is a pleasant bonus, but it’s crucial if you intend to thread pipes.

When using an adjustable pipe cutter, hold it firmly on the pipe and spin it around without tightening it to create a groove for a straight cut. If the grooves don’t create a complete circle but instead spiral, clean the tool and try again.

Apply pipe joint compound to the pipes’ exposed threads if you’re joining them.

It’s important to employ a Teflon-containing pipe compound because Teflon expands in the presence of moisture and stops leaks.

Is There Any Material That A Pipe Cutter Cannot Cut?

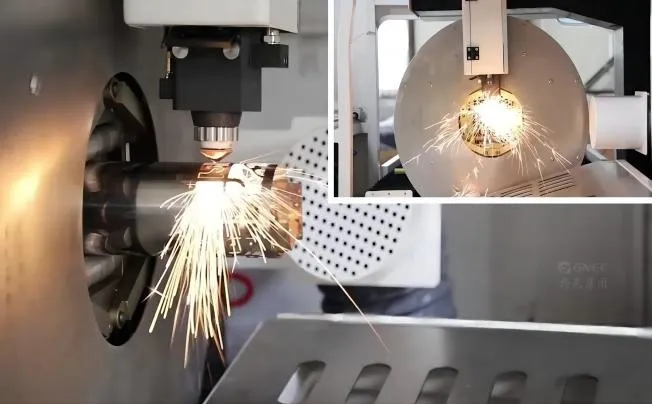

1. Soft metals are ideal for the majority of adjustable cutters

Any pipe cutter with an adjustable jaw width should be able to handle copper, brass, and aluminum pipes without any issues. You’ll need a specific type with hardened wheels and, if you’re getting heavy-duty, an extra-long handle for increased leverage to cut through steel or iron.

2. The capacity of PVC cutters varies by product

Plastic pipes made of PEX, PP, CPVC, and PE are all easily cut with almost any PVC cutter. Check your particular model to determine if it is also capable of cutting PVDF, PB, or ABS plastics. Any rigid, light-colored plastic pipe put within a home is likely made of PVC.

Squeezing old plastic pipes with a scissor- or ratchet-style cutter may result in cracks since they are more brittle. A hacksaw or an adjustable pipe cutter are safer choices. When the blade gets dull and the temperature drops, there is an increased chance of cracking.

Stainless Steel Pipe Cutter Be Used?">

Stainless Steel Pipe Cutter Be Used?">