Why need bending stainless steel pipe?

1. Heat tint must be avoided or eliminated at welded junctions, such as those between straight pipes and elbows. Applying shielding gas may be challenging, especially on-site. Acid-containing materials are used in the chemical removal of heat tint, which typically involves taking safety and environmental precautions. Only the pipe’s outside can be mechanically removed. These fabrication processes are avoided when a stainless steel pipe is bent in one piece.

2. Crevices are a given in mechanical couplings that have couplers or flanges. These could be unpleasant depending on the circumstances because they can catch caustic substances. Crevice corrosion is another issue that needs to be considered. A continuous, even surface is guaranteed by bending stainless steel pipe.

Therefore, bending stainless steel pipe may be the simplest and most effective way to complete a design assignment. One of the most widely utilized manufacturing methods for stainless steel is pipe bending.

Methods for bending stainless steel pipe

To satisfy the needs of stainless steel pipe and tubing of various sizes and materials (such as 204, 304, and 316), there are four techniques of bending. Stainless steel pipe can be bent using a variety of techniques. Three-roll benders, also known as section benders, profile benders, or angle rolls, can curve tubing if the bend has a big radius. Mandrel pipe bending is a technique that can be used to bend a pipe on a rotary-draw bender if the pipe has a small radius.

Method 1——Compression Bending: In compression bending, a stainless steel pipe is held in position while being bent around a die or other type of former. Simple manual pipe and tube benders as well as hand bending, such as wrapping a stainless steel pipe around your knee, are used in the simplest applications.

Method 2——Draw Bending.: Draw bending works best with tubing that has bigger walls or is constructed of a tougher material, such as stainless steel.

Method 3——Roll Bending: In roll bending, the stainless steel pipe is often rolled through the machine as the top roller presses down to bend the pipe. Three rolls are frequently arranged in a pyramid pattern for this purpose. Large bends in stainless steel pipe or tubing workpieces in construction frequently need the use of tube rollers.

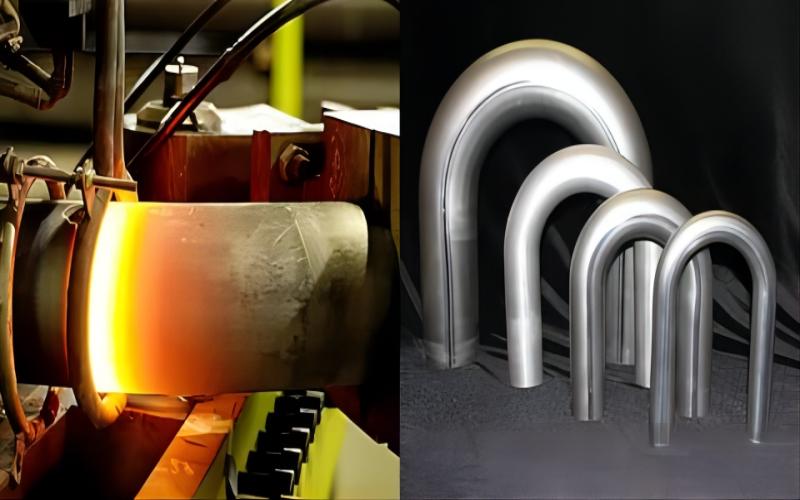

Method 4——Hot Bending: A thermal induction coil is wrapped around a stainless steel pipe at the bend for induction bending. To bend the softened pipe to the appropriate angle, the operator warms the coil and applies pressure. Because stainless steel pipe and tubing often don’t come in extremely big diameters, this is the only practical method we are aware of for bending stainless steel pipe.

Commonly used bending methods of stainless steel pipes

The two primary forms of CNC bending machines are the CNC pipe bender and the CNC profile bender. In both types, the rollers are regarded as tools since they need to be changed to accommodate various tube diameters.

1. The profile bending machine, also known as a roll bender or section bender, only has three rolls, one or more of which are powered in rotation to draw the pipe in and between them. To get the correct bend radius, the pipe is frequently run back and forth between the rolls several times. This kind may be CNC, NC, or semi-manual.

2. The second type of CNC pipe bending machine (draw bending) uses rolls that are free to rotate while the pipe is pushed through them (thus, push bending). We refer to this type—which is often CNC-operated and bends pipes in a single motion—as a CNC pipe bending machine.

Stainless Steel Pipe Bending Advice

Since items for the food and pharmaceutical industries frequently use bent stainless pipes, care must be taken to prevent carbon contamination of the steel. To prevent such contamination, the equipment should be cleaned and readied. Additionally, care should be made to keep metal strapping away from the stainless components. The pipe can be shielded during shipment using cardboard, wood, or plastic.

Stainless steel pipe can be bent, and then the ends can be flared by sliding a nut and sleeve over them. This is how process pipework is frequently provided. For instance, 316 seamless stainless steel pipe with a 1.5 OD and 0.065 walls (16 ga) was formed into a flat-back U by bending it twice at 90 degrees. The flare at the ends was 37 degrees JIC. In applications involving extremely high pressure, such as fuel distribution and fluid power, JIC (Joint Industry Council) fittings are frequently employed. Another pipe of the same size and grade was offset-bent.